Cylinder rounding device of pressure vessel

A technology of pressure vessel and physical school, applied in the field of pressure vessel cylinder rounding device, can solve the problems of wasting manpower, low regulation efficiency, poor precision, etc., and achieve the effect of improving the degree of automation and improving regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

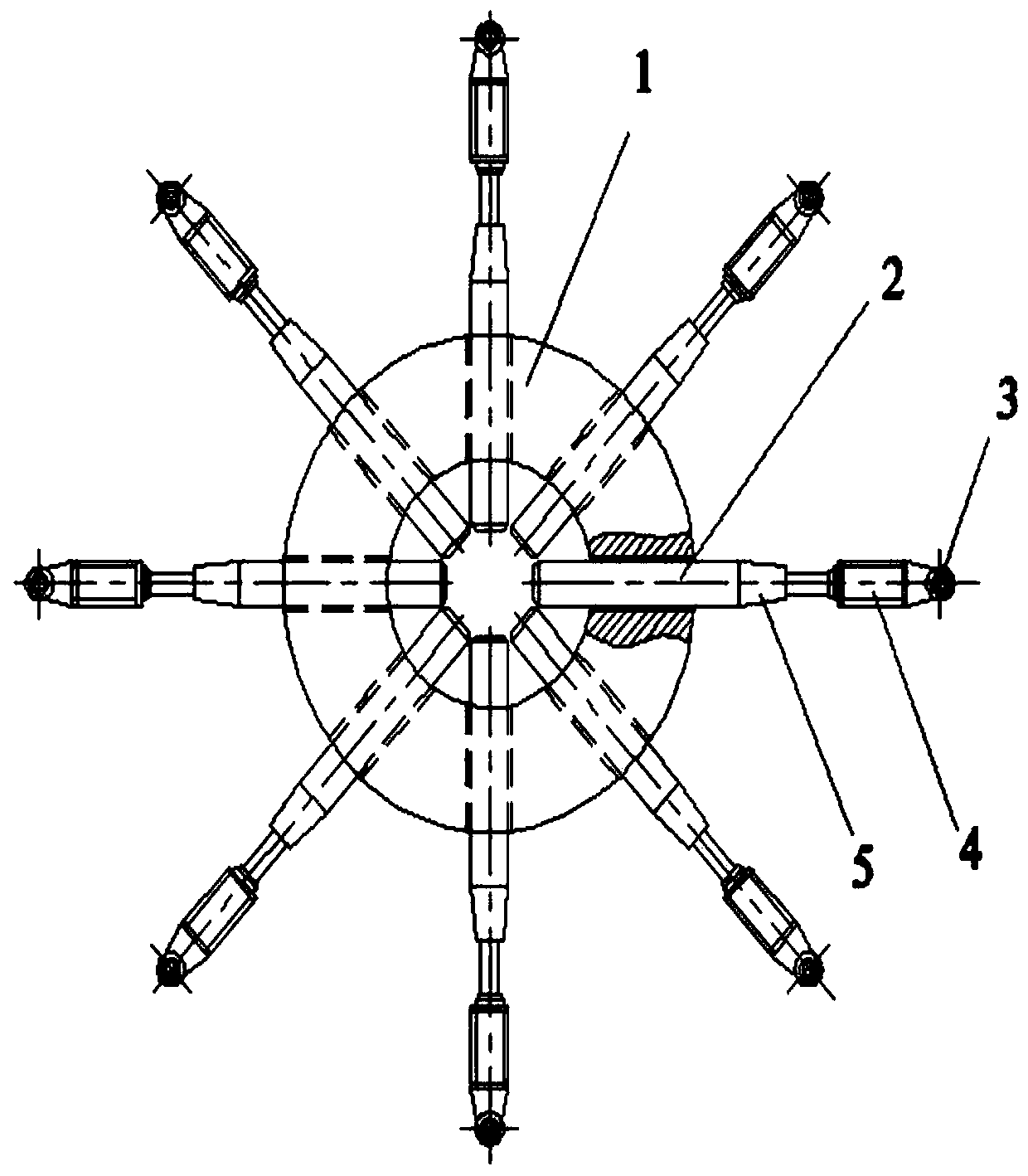

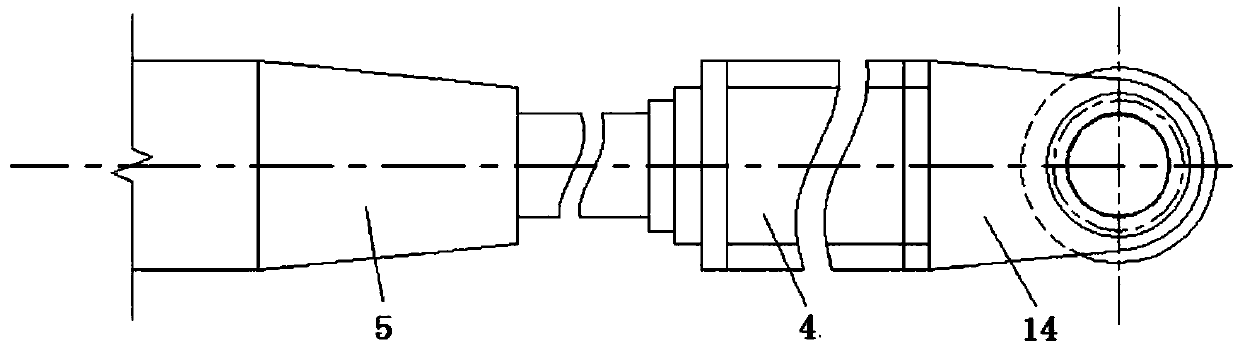

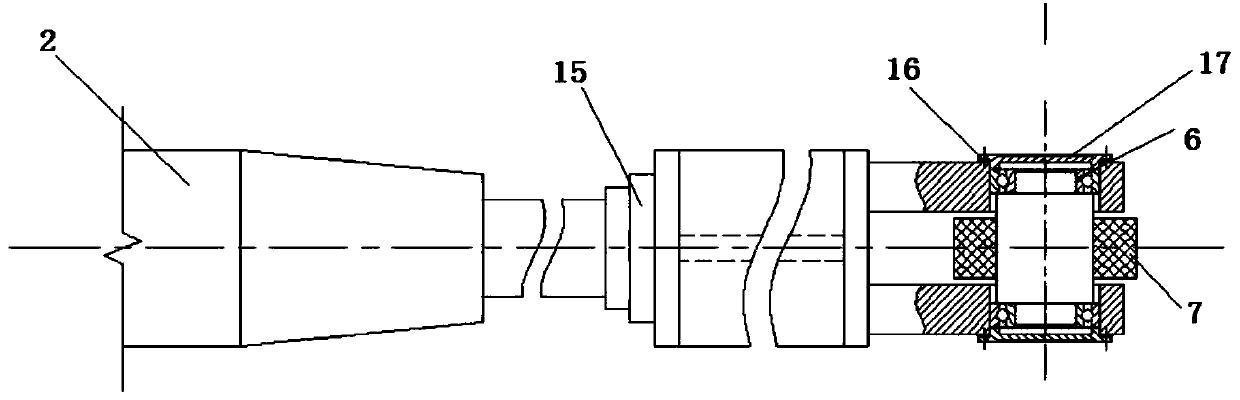

[0020] Such as figure 1 As shown, a pressure vessel cylinder circle correction device includes: a hollow disc support 1, 8 support rods and a detection mechanism, and the support rods include: a steel rod 2, a jack 5, a roller support head 3 and a support arm, One end of the steel rod 2 is uniformly threaded on the hollow disc support 1, the two ends of the jack 5 are respectively welded to the steel rod 2 and the support arm, and the support arm is connected to the roller support head 3, the steel rod 2 and the jack 5 is also provided with reinforcing backing plate 15. The support roller 7 includes: a bearing 6, 2 bearing end covers 17, 2 support plates 14, a shaft and a roller 7, the shaft is arranged on the bearing 6 at both ends of the bearing 6 cover, and the bearing 6 cover is set outside the cover and connected by bolts The support plate 14, the roller 7 is sleeved on the shaft and arranged between the support plates 14, and the bearing seal 16 is also provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com