Fire-fighting robot spraying curve adjusting method and device based on multi-view vision

A fire-fighting robot, spray curve technology, applied in the direction of instruments, computer control, computer parts, etc., can solve the problems of people being unable to approach the scene, single spray mode, large fire-fighting flow of fire-fighting robots, etc., to improve work efficiency and reduce workload. , the effect of improving efficiency and fire extinguishing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

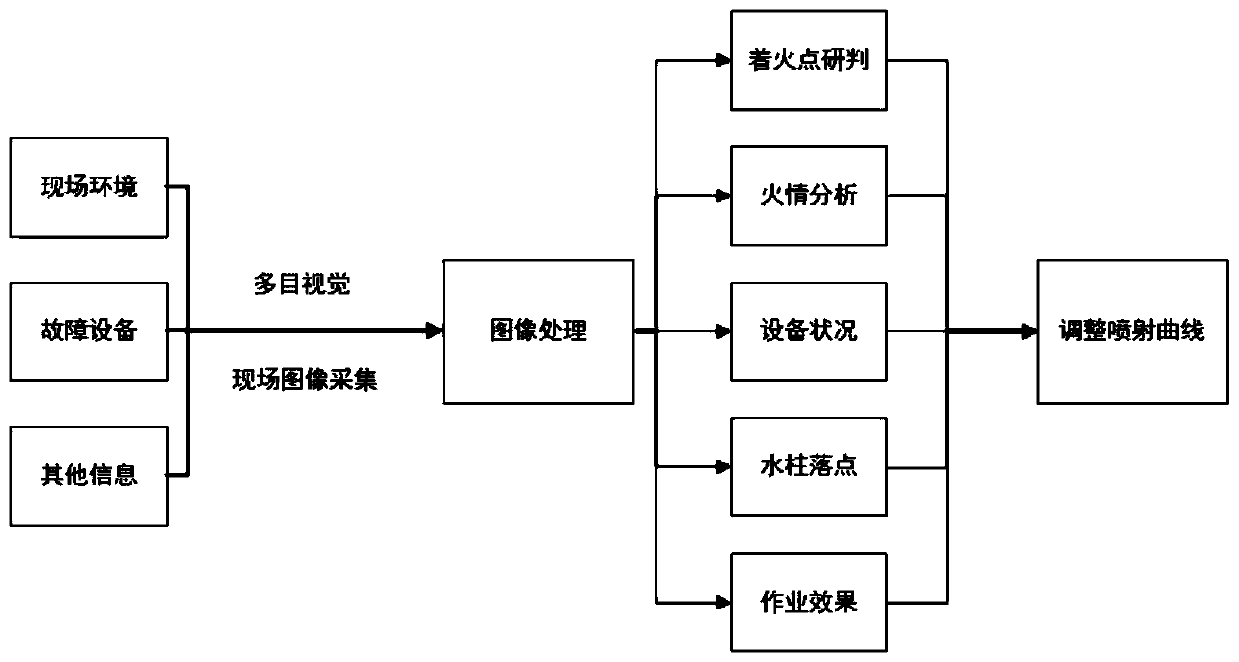

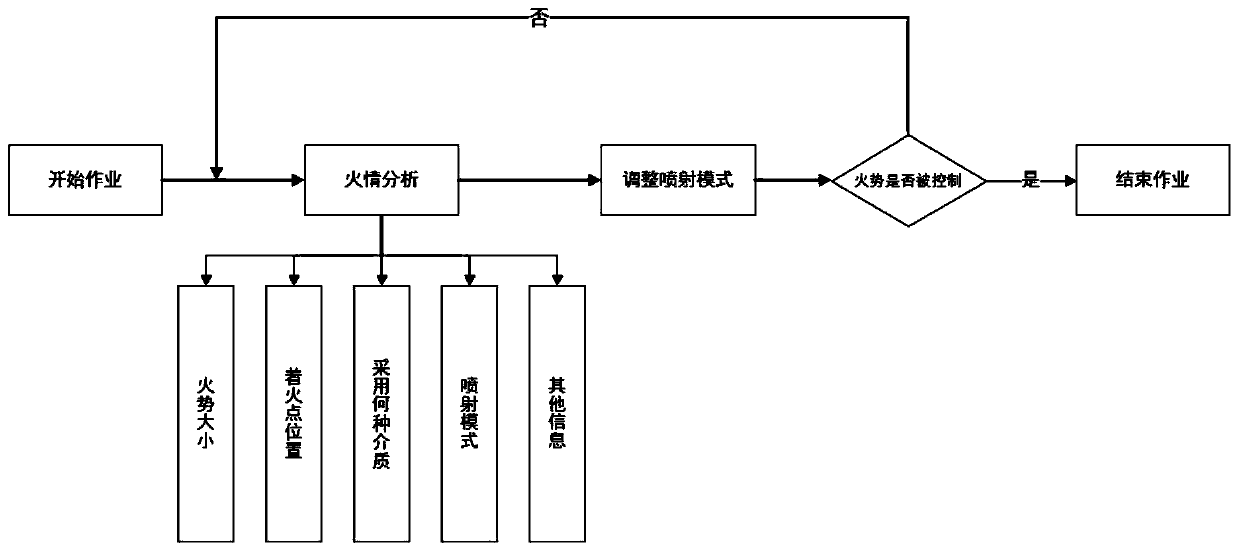

[0054] figure 1 The flow chart of the method for adjusting the spraying curve of a fire fighting robot based on multi-eye vision involved in this embodiment. Such as figure 1 As shown, the fire robot injection curve adjustment method may further comprise the steps:

[0055] S101. Acquire visual image information and infrared image information of a scene environment collected by a multi-eye vision device.

[0056] The image information of the scene environment is collected through the ordinary vision camera of the multi-eye vision device, including the image information of the equipment in the scene environment, the image information of the fire situation in the scene environment, and the smoke concentration information in the scene environment. If you are at the scene of a fire, you can collect visual image information such as fire equipment, fire size, and smoke density through multi-eye vision equipment.

[0057] The infrared images of the scene environment are collected ...

Embodiment 2

[0095] This embodiment provides a fire robot spray curve adjustment device based on multi-eye vision, the device includes:

[0096] The image acquisition module is used to acquire the visual image information and infrared image information of the scene environment collected by the multi-eye vision equipment;

[0097] The image preprocessing module is used to preprocess the obtained visual image information and infrared image information respectively;

[0098] The fire area determination module is used to determine the fire area according to the preprocessing results of the visual image information and the infrared image information;

[0099] The injection position determination module is used to establish the injection curve model according to the fire area, identify the water column drop point, and determine the optimal injection angle and injection flow rate;

[0100] The injection mode adjustment module is used to analyze the condition of the fire equipment in the fire are...

Embodiment 3

[0126] This embodiment provides a computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following steps are implemented;

[0127] Obtain the visual image information and infrared image information of the scene environment collected by the multi-eye vision equipment;

[0128] Preprocessing the obtained visual image information and infrared image information respectively;

[0129] Determine the fire area according to the preprocessing results of visual image information and infrared image information;

[0130] According to the fire area, establish the injection curve model, identify the water column drop point, and determine the optimal injection angle and injection flow rate;

[0131] Analyze the condition of the fire equipment in the fire area, and determine the best fire extinguishing position and distance;

[0132] Judging the size of the fire of the ignition equipment, select the best injection mode. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com