Online ash removal device of intelligent fan rotor

A technology of fan rotor and dust cleaning device, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve problems such as deterioration of rotor dynamic balance, long processing time, and falling off of dusting speed , to achieve the effect of increasing the continuous use time, prolonging the continuous use time, and improving the fan operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides an intelligent blower rotor online cleaning device. The fan is a converter gas fan, and the conveying gas is converter gas. The motor power is 2240kW, and the rated speed is 1488 rpm. Low-speed interval operation, high-speed operation speed of 1400 rpm, generally continuous operation for 45 minutes to low-speed operation, low-speed operation speed of 600 rpm, continuous operation for 15 minutes to high-speed operation, and so on. Because the gas contains a large amount of dust and moisture, the fan rotor is easy to accumulate dust before installing an online dust removal device for the intelligent fan rotor of the present invention, and it needs to be shut down every 2-5 days to clean the dust accumulation of the rotor;

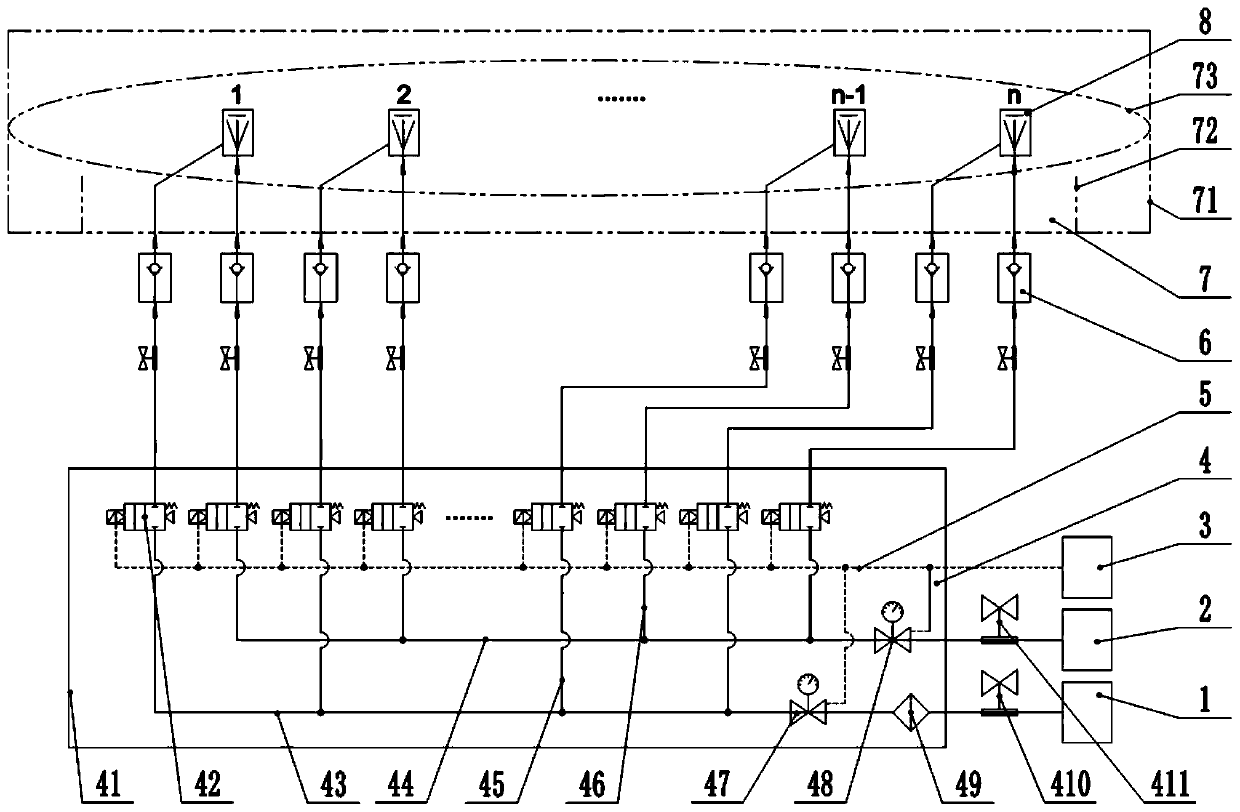

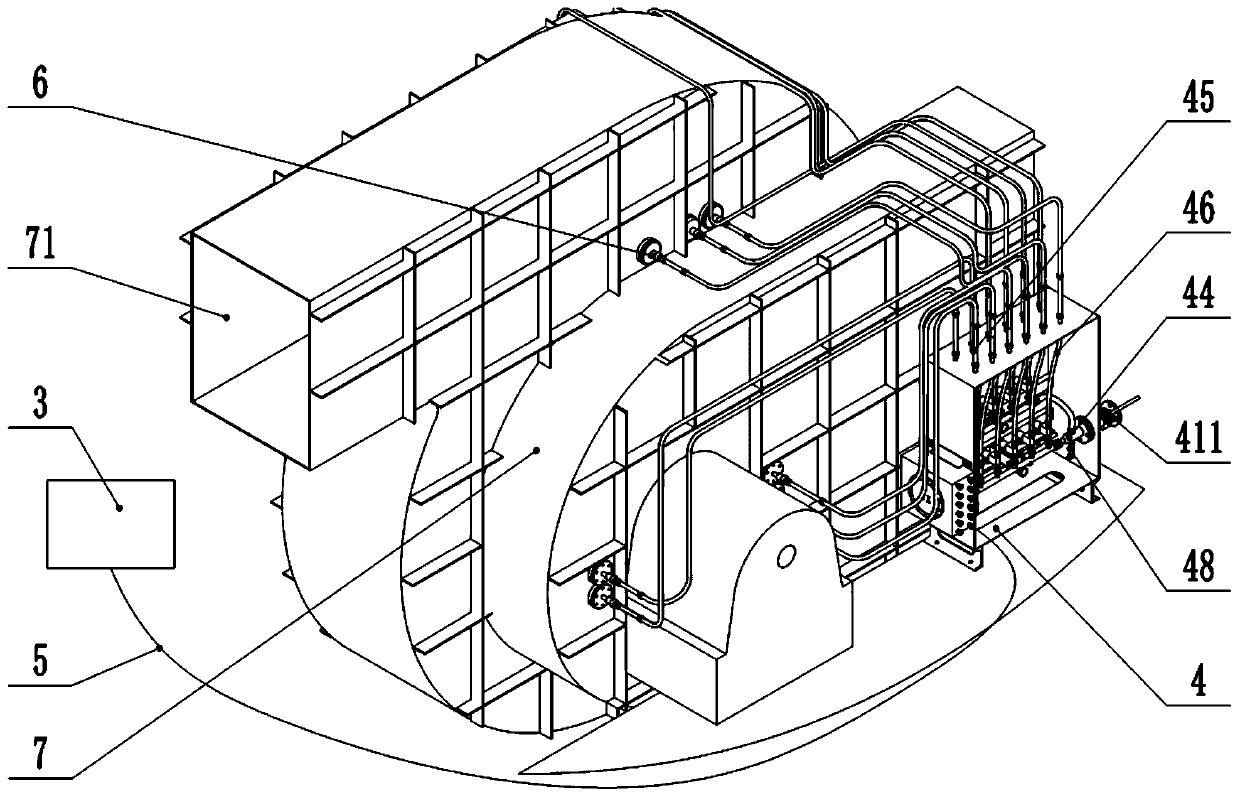

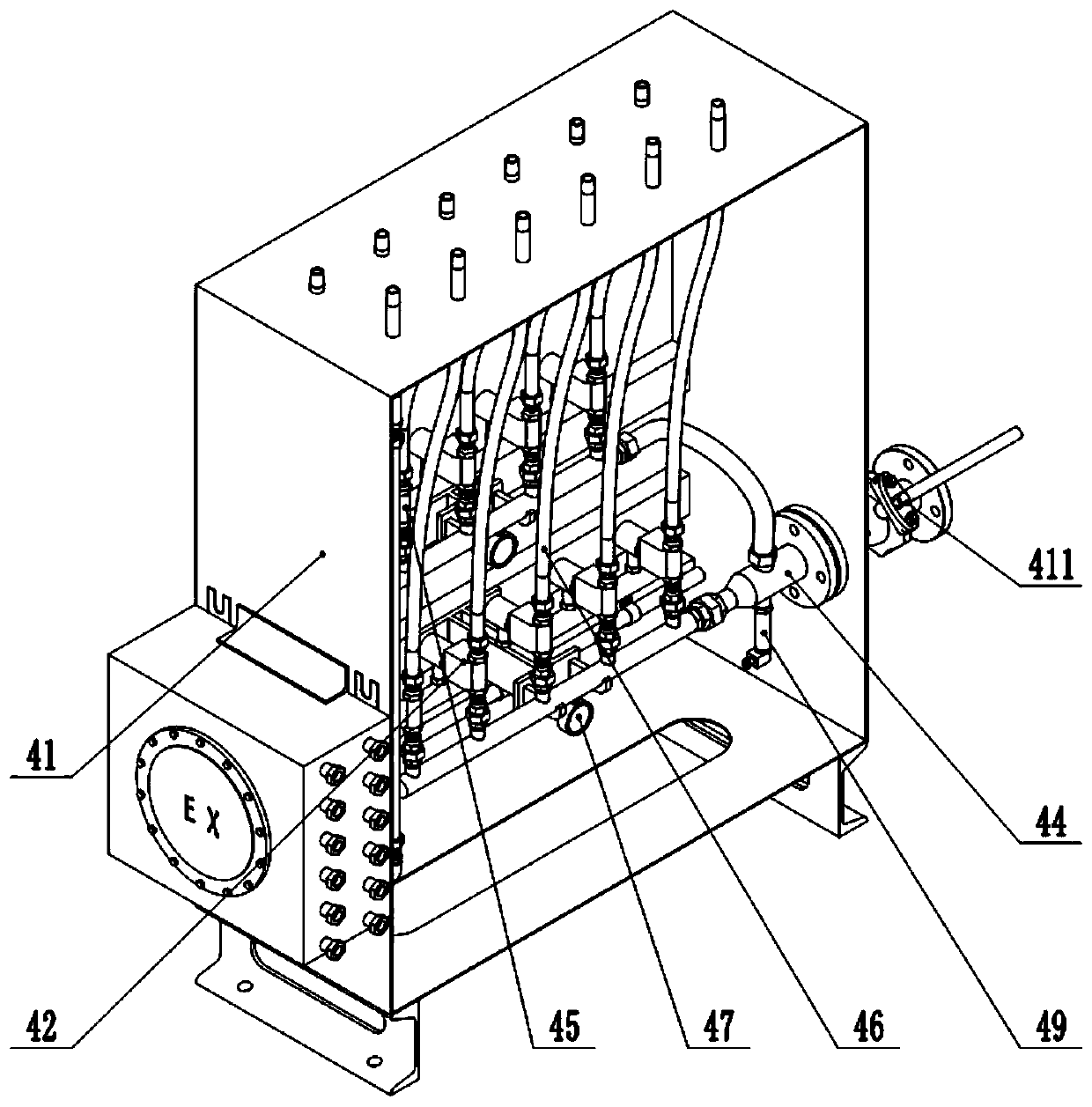

[0026]For this reason, this embodiment provides an intelligent fan rotor online cleaning device to solve the above-mentioned problems of fan rotor dust accumulation and online cleaning, including a liquid source 1, a compressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com