Impeller capable of preventing ash sticking of converter primary fan

A technology of fan impeller and secondary fan, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of re-spraying, surface wear, sticking ash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

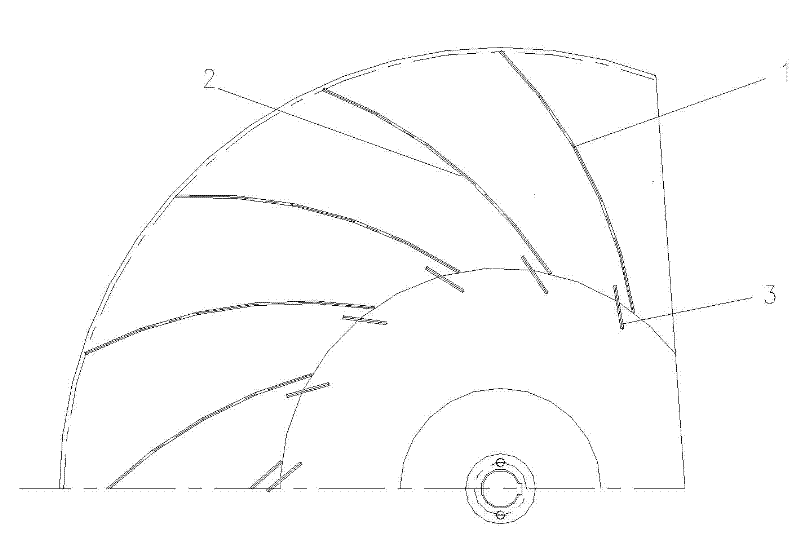

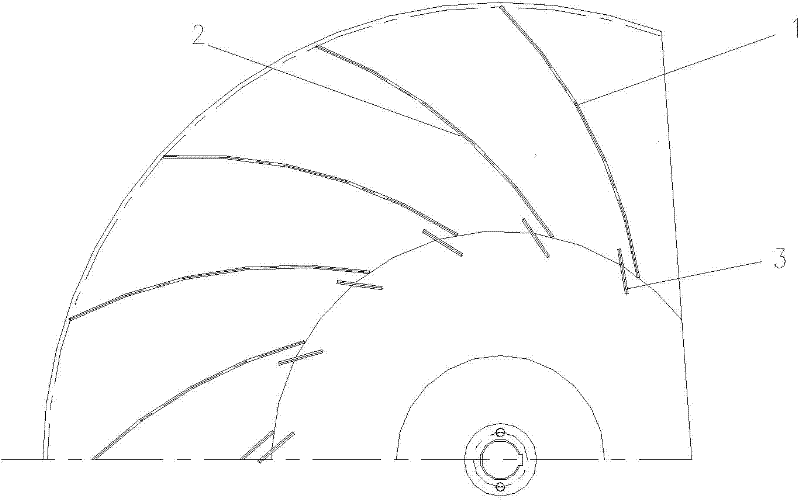

[0014] like figure 1 As shown, a converter primary fan impeller with anti-adhesive dust, the surface of the fan impeller is coated with nano-dust-proof coating 2, and the nano-dust-proof coating 2 is coated on the middle and back section of the leeward side of the blade 1. The middle plate of the impeller 1 is provided with rectifying guide vanes 3 near the inlet of the blades.

[0015] Through the rectifying guide vanes 3, part of the airflow at the air inlet passes through the diversion effect of the small blades to accelerate the flow velocity at the back of the blade 1, so that the airflow rectified by the rectifying guide vanes 3 directly scours the leeward front section of the blade 1, so that the blade 1 is leeward. The front section is not easy to accumulate dust.

[0016] According to the same boundary conditions, the airflow effect of the small blade is recalculated, and the calculation results show that the flow velocity of the leeward front section of the blade is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com