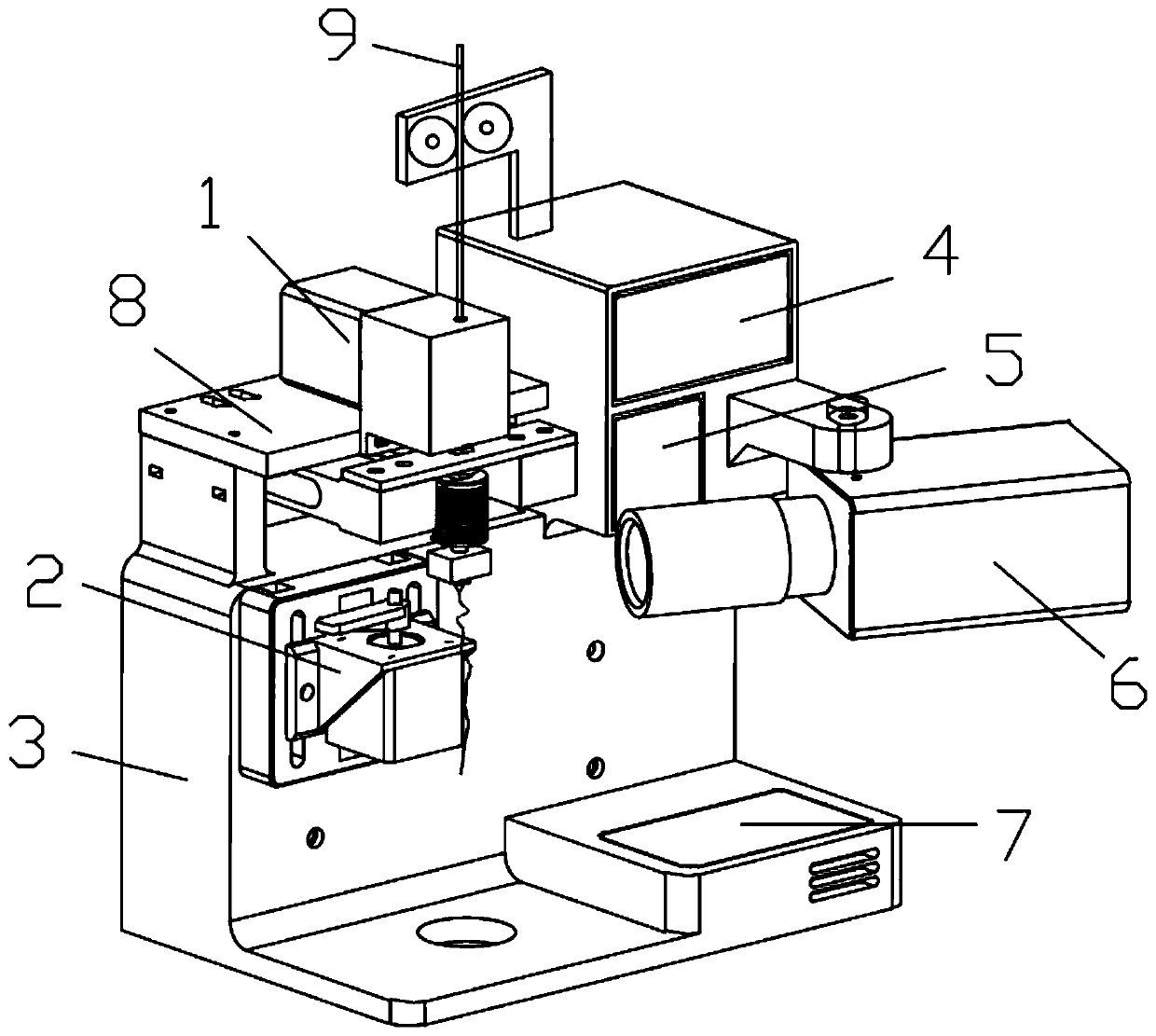

Detection device and method of spray head mechanism of 3D printer

A 3D printer and detection device technology, applied in the field of 3D printing, can solve the problems of long test cycle and many interference factors, and achieve the effect of high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

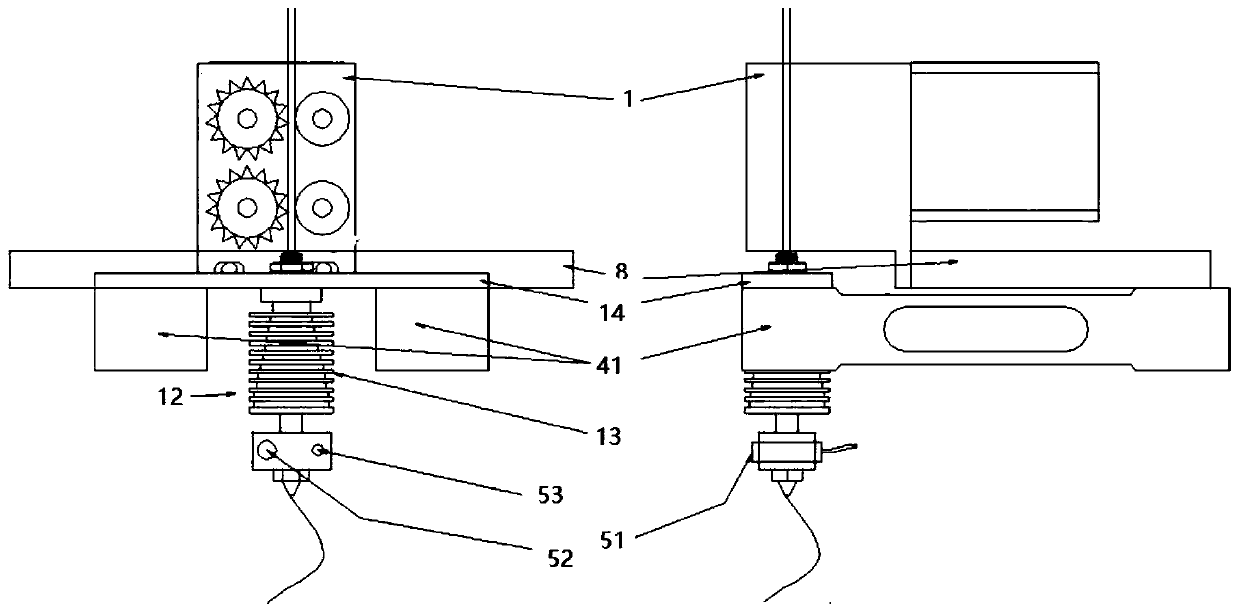

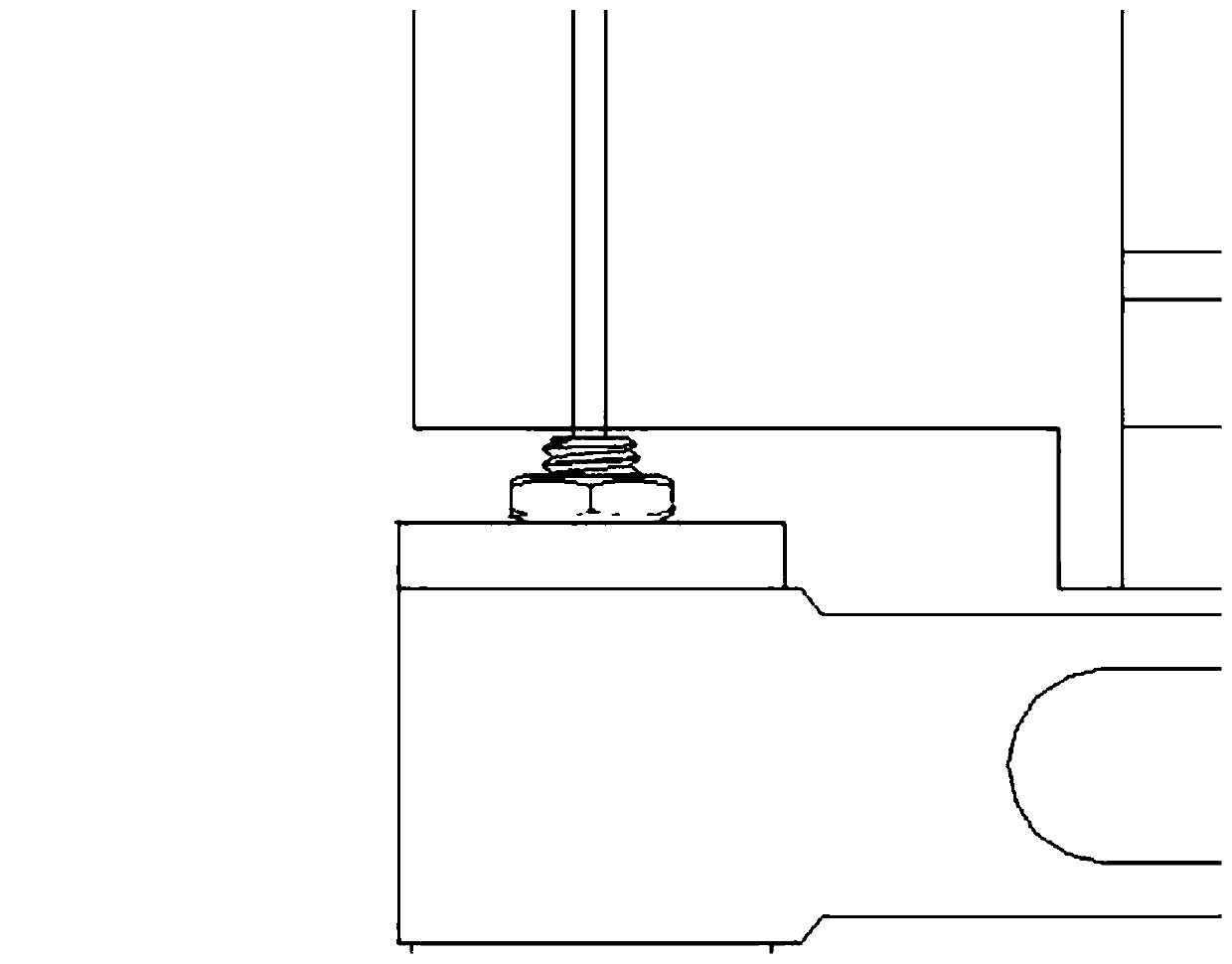

[0065] In the existing technology, a certain heating temperature and printing speed are usually set before 3D printing. The linear material is melted and extruded in the nozzle, and the actual temperature of the material extruded from the nozzle (ie, the outlet temperature) is generally low. The actual temperature is affected by the set heating temperature and printing speed, and there is currently no method to specifically test the above actual temperature. At the same time, the actual temperature of the material will have a great influence on the viscosity of the material. Generally speaking, the lower the temperature, the higher the viscosity of the material. This requires the extruder of the nozzle mechanism to provide a strong extrusion pressure. The material is extruded from the nozzle, and currently there is no instrument and method to test this extrusion pressure. In addition, after the material stops extruding, there will be "nozzle flashing" problem, and there is cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com