Number spraying machine capable of achieving automatic switching between high number spraying speed and low number spraying speed and number spraying method thereof

A technology of automatic switching and number spraying machine, which is applied in copying/marking methods, typewriters, printing, etc., can solve the problems of serious stacking of billets in the cooling bed, short continuous casting machine process, and affecting production, so as to avoid the non-stacking of billets in the cooling bed , Improve the efficiency of spraying number, and the effect of smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

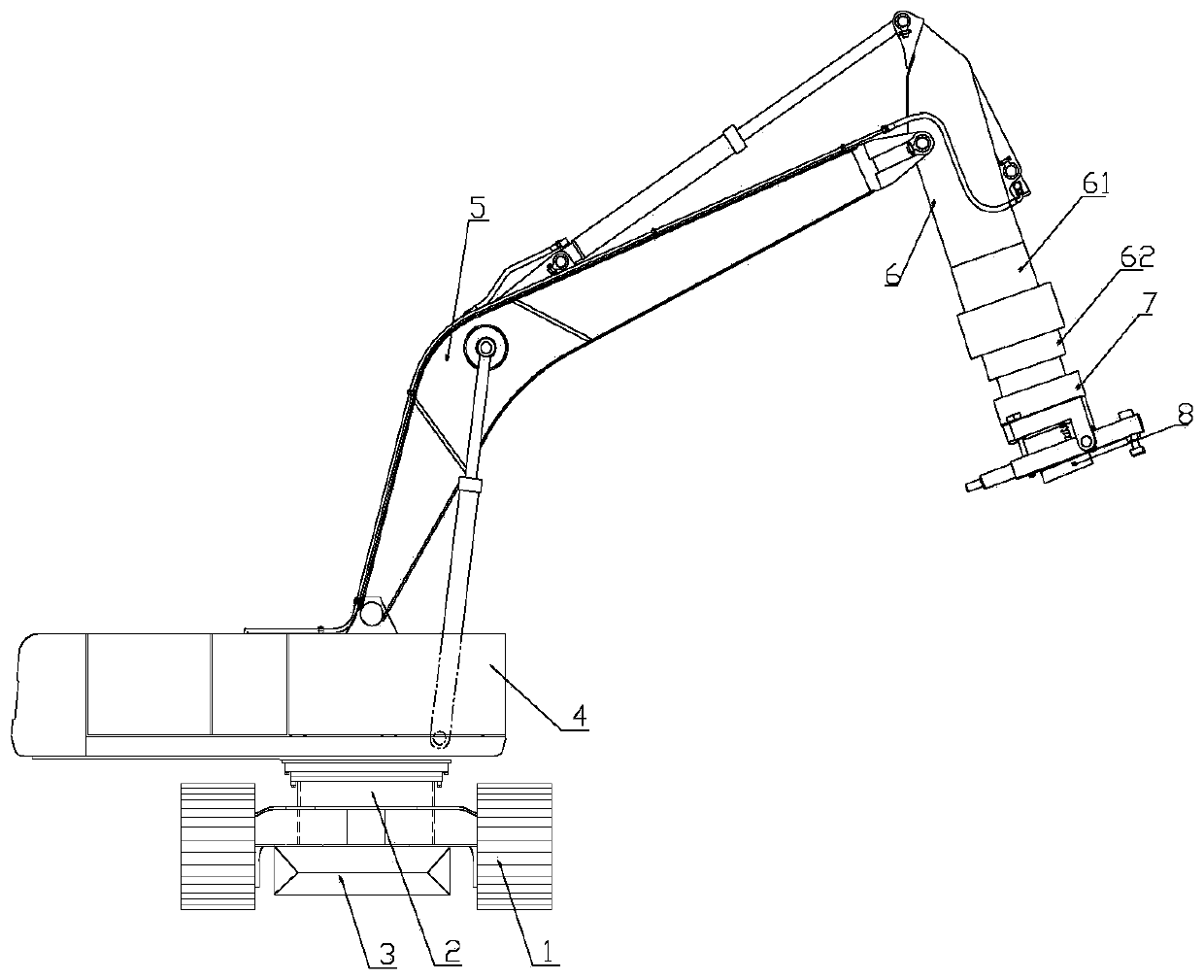

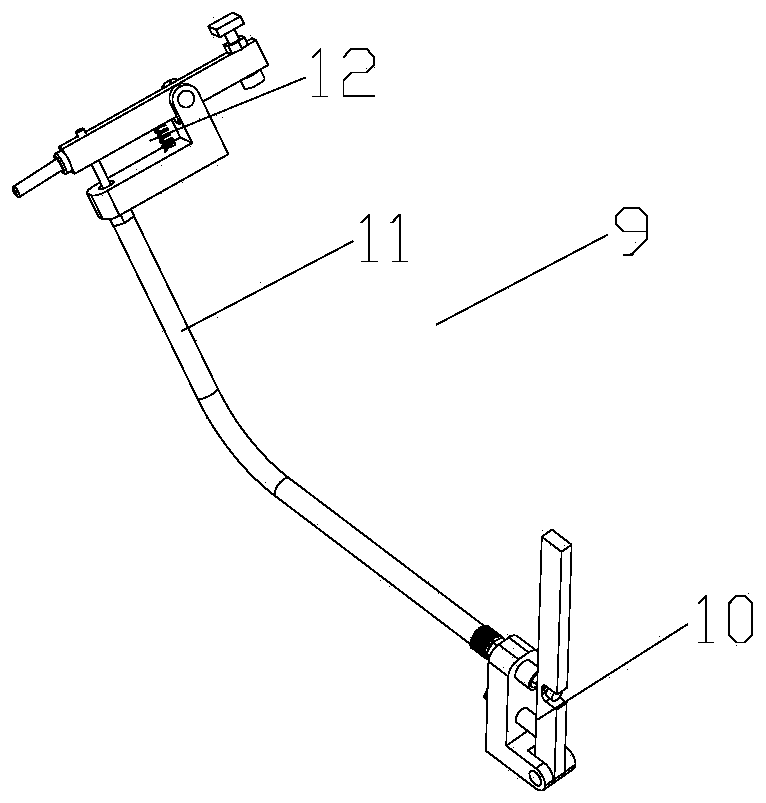

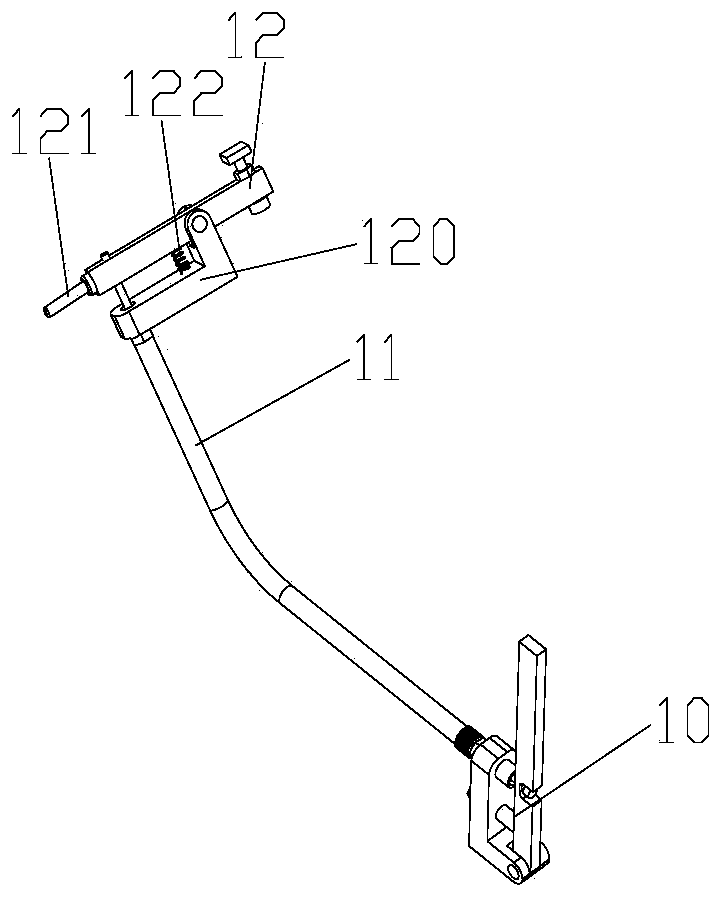

[0029] see Figure 1 to Figure 3 The technical solution provided by the present invention is a number spraying machine that can automatically switch between fast and slow speed spraying numbers, wherein it includes two oppositely arranged driving wheels 1, a driving base 2 arranged between the two driving wheels 1, The feeding structure 3 and the operating platform 4 arranged on the drive axle housing 2, and the cantilever 5 arranged on the operating platform 4, one end of the cantilever 5 is arranged on the turntable controlled by the host of the operating platform 4 On the seat, the other end is hinged with a power arm 6, and the end of the power arm 6 is provided with a number spraying mechanism;

[0030] The number spraying machine also includes a control box arranged on the driving base, and the electric control circuit of the feeding structure 3, the operating platform 4, the cantilever 5, the power arm 6 and the number spraying mechanism are connected with the control b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com