Silicon wafer boxing machine

A cartoning machine and silicon wafer technology, applied in packaging and other directions, can solve the problems of high personnel dependence, increased cartoning cost, low clamping and transportation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

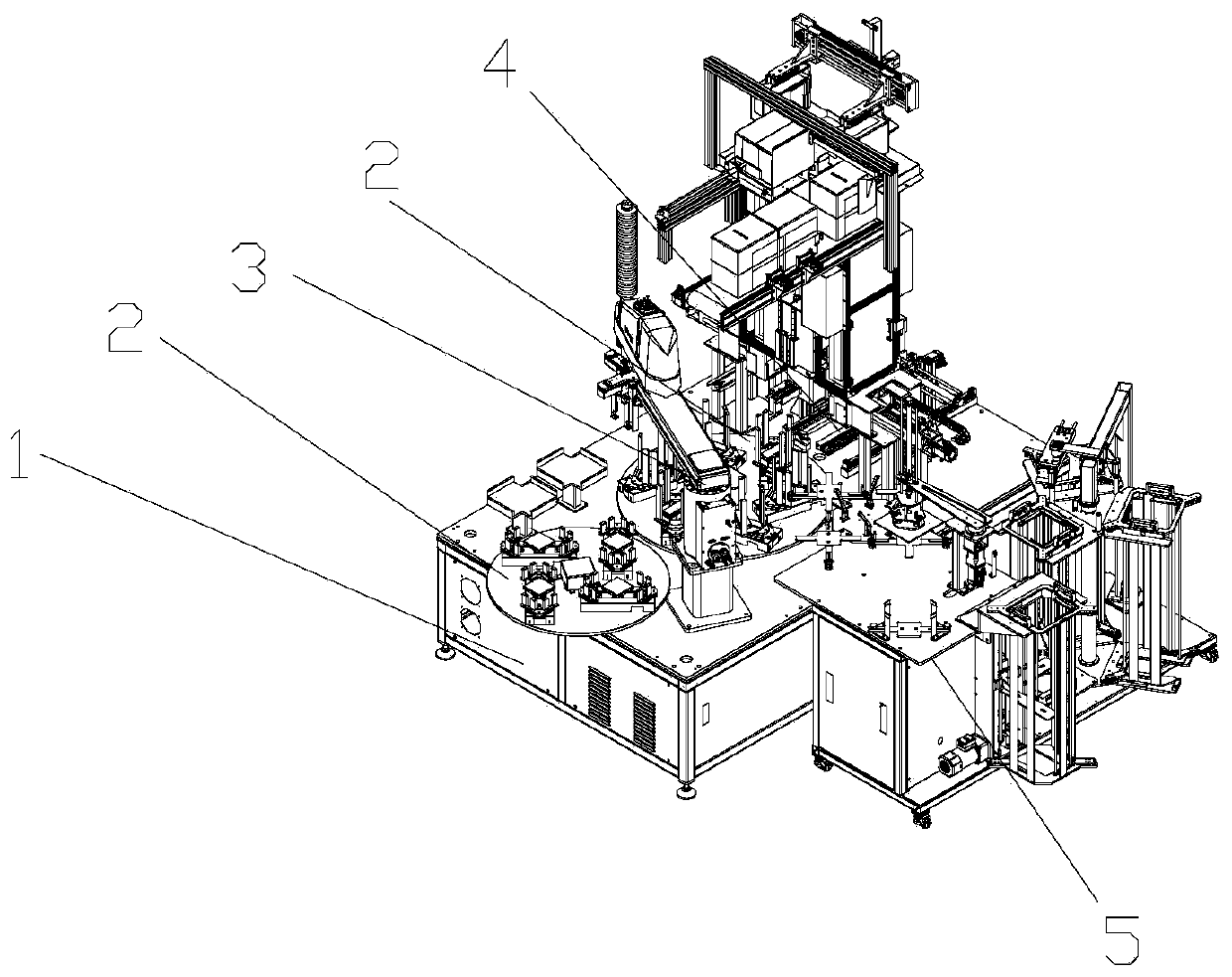

[0051] Such as figure 1 A silicon wafer cartoning machine shown includes a main frame 1, a turntable 2, a mechanical gripper 3, a box loading mechanism 4, and an interlayer configuration mechanism 5. The interlayer configuration mechanism 5 is arranged on one side of the main frame 1, and two turntables 2 are installed side by side on the table of the main frame 1, the mechanical gripper 3 is installed between the two turntables 2 and the interlayer arrangement mechanism 5, and the box loading mechanism 4 is installed on one side of the turntable 2. The quality of the silicon wafers is firstly distinguished by an external device, and the silicon wafers with different degrees of quality are distinguished and placed in the place, and then the interlayer configured on the interlayer configuration mechanism 5 is grabbed by the mechanical gripper, and the silicon wafer and the interlayer are placed together. On the other turntable 2, finally, the box loading mechanism 4 picks up th...

Embodiment 2

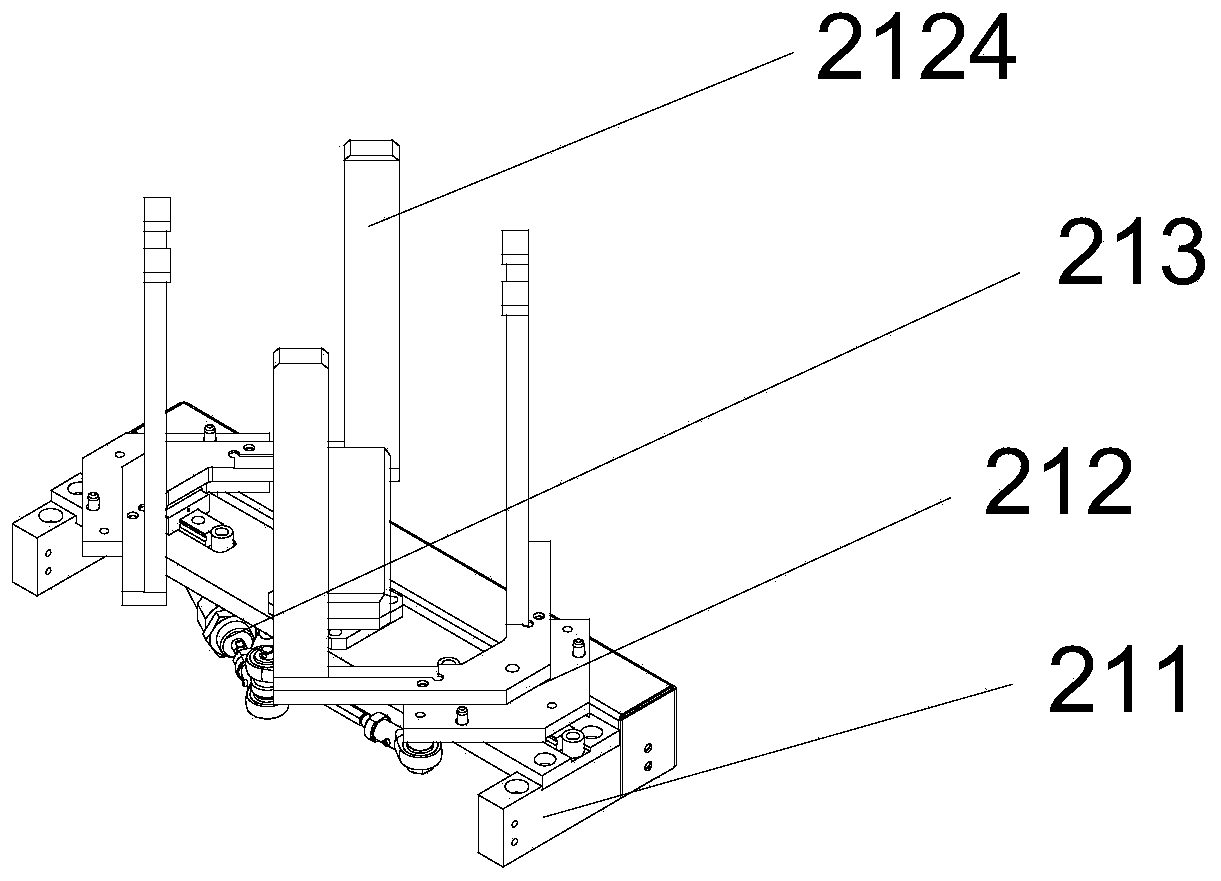

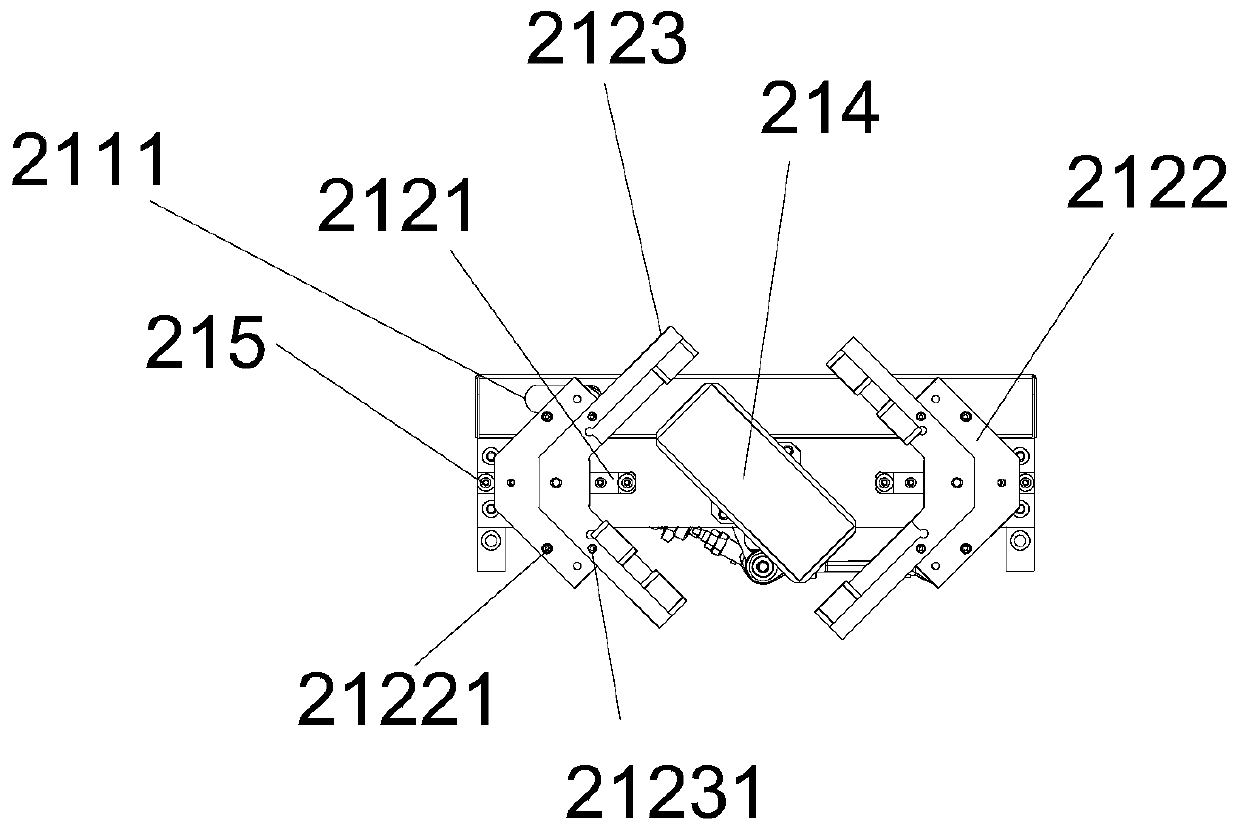

[0060] A silicon wafer cartoning machine as shown in Embodiment 1, the only difference is that the clamping module 212 includes a linear slide rail 1 2121, a slider connecting plate 2122, a backing plate mounting plate 2123, a backing plate 2124, and a linear slide rail One 2121 is fixed on both ends of the installation plate one 211, and each linear slide rail one 2121 is slidably provided with a slider connecting plate 2122, and the leaning plate mounting plate 2123 is clamped on the slider connecting plate 2122, and the leaning plate 2124 is fixed On the board mounting plate 2123.

[0061] Such as figure 2 , image 3 , Figure 4 As shown, the driving module 213 includes a driving cylinder 1 2131, a rotating plate 2132, a connecting rod 2133, and a connecting rod 2 2134. The driving cylinder 1 2131 is fixed on the mounting plate 1 211, and the rotating plate 2132 is rotatably mounted on the mounting plate 1 211. One end of the rotating plate 2132 is connected to the driv...

Embodiment 3

[0068] A kind of silicon cartoning machine shown in embodiment 1, its difference is only, as Figure 9 , Figure 10 , Figure 11 As shown, the silicon wafer tightening module 41 includes a tightening fixture 411, a driving motor 41212, a coupling 413, a tightening screw 414, a tightening nut 415, and a pressing plate structure 416. The driving motor 41212 is installed on the tightening fixture 411 One end of the coupling 413 is connected to the output end of the driving motor 41212, and the other end of the coupling 413 is connected to the tightening screw 414, and the tightening screw 414 is equipped with two tightening nuts 415 that turn in opposite directions, each tightening A pressing plate structure 416 is slidably disposed on the tight nut 415 .

[0069]The tightening nut 415 is driven to move up and down by the rotation of the drive motor 412 , thereby realizing the up and down movement of the pressing plate structure 416 . Tightening the fixed frame 411 also includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com