An active material-pushing type sub-unloading system

An active and unloading device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that the separation and unloading of materials cannot be realized, the section of separation and unloading is too long, and the included angle cannot be too large. , to achieve the effect of saving equipment investment, short unloading area and small unloading section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

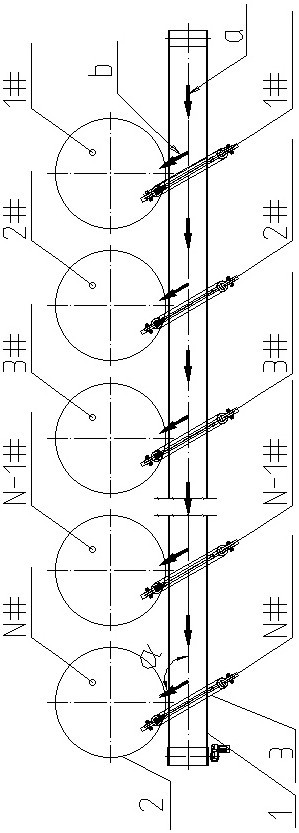

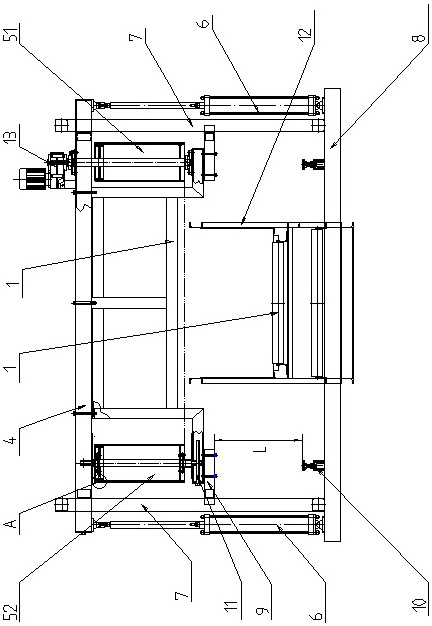

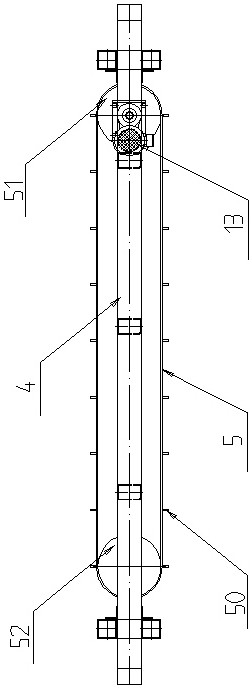

[0035] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing, figure 1 The arrow shown in a is the direction of material movement, and the arrow shown in b is the direction of material discharge.

[0036] Such as Figure 1 to Figure 4 As shown, this embodiment discloses an active material-pushing type separation and unloading system, which includes a conveying line 1 for conveying materials. The conveying line 1 can be a belt conveyor. Arrange the charging container 2 arranged in a straight line, and the charging container 2 along the conveying direction is 1# charging container, 2# charging container, 3# charging container...N-1# charging container and N# charging container container.

[0037] Between the conveying line 1 and each corresponding charging container 2, there are distributing and unloading devices 3 that guide the materials on the conveying line 1 to the charging containers 2. Unloading device, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com