An incoming wire device for a textile machine

A technology of textile machines and wires, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve problems such as dust removal and static electricity removal of threads that cannot be used for textiles, product quality reduction, and a large amount of dust attached to it. Long service life, improved product quality, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

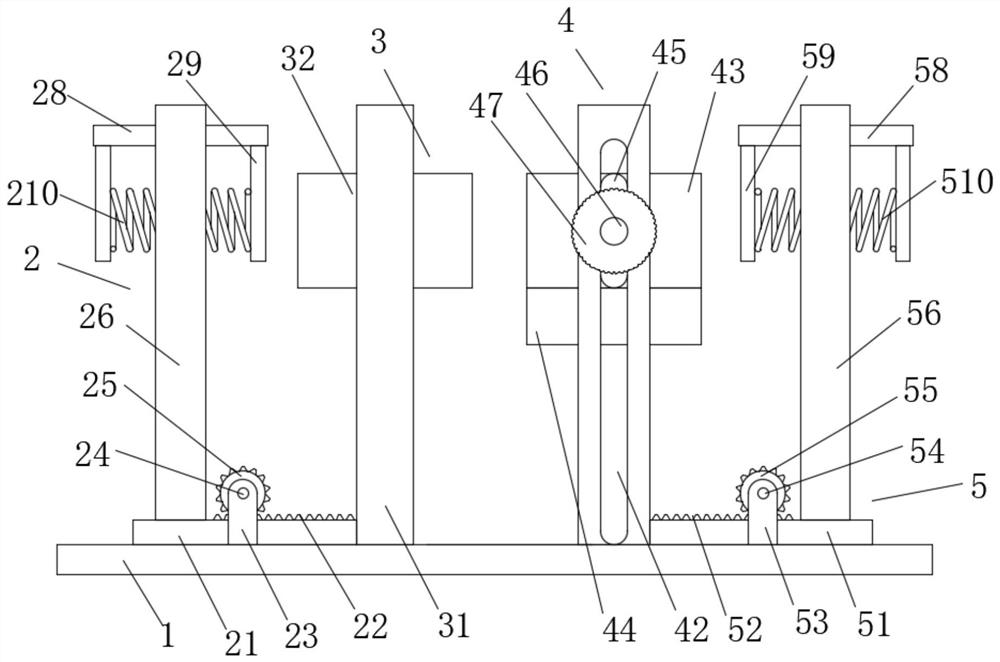

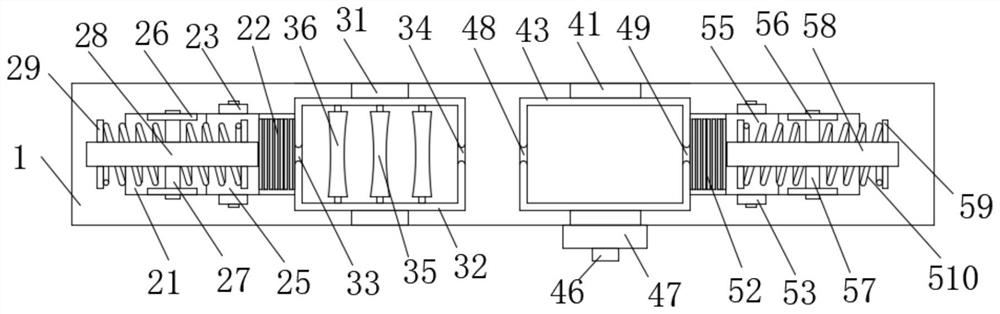

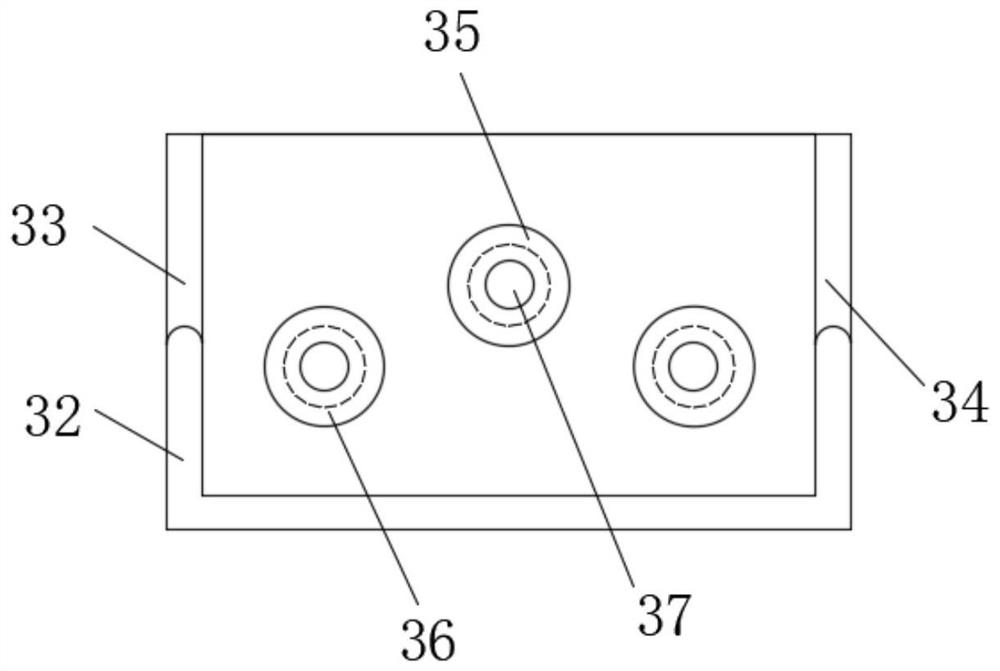

[0022] Example: such as Figure 1-4 As shown, an incoming wire device for a textile machine of the present invention includes a mounting plate 1, a first wire mechanism 2, a static elimination mechanism 3, a dust removal mechanism 4 and a second wire mechanism 5, the first wire mechanism 2, the The electrostatic mechanism 3, the dust removal mechanism 4 and the second wire mechanism 5 are all arranged on the top of the mounting plate 1, the first wire mechanism 2 is arranged on one side of the static electricity removal mechanism 3, and the dust removal mechanism 4 is arranged on the static electricity removal mechanism 3 The side away from the first wire mechanism 2, the second wire mechanism 5 is arranged on the side of the dust removal mechanism 4 away from the static elimination mechanism 3, the first wire mechanism 2 is composed of the first slide plate 21, the first rack 22 , the first support frame 23, the first rotating shaft 24, the first gear 25, the second supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com