A kind of preparation method of tin sulfide composite negative electrode material

A technology of stannous sulfide and negative electrode materials, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve problems such as poor cycle life and rapid capacity decay, and achieve improved cycle life, low preparation cost, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

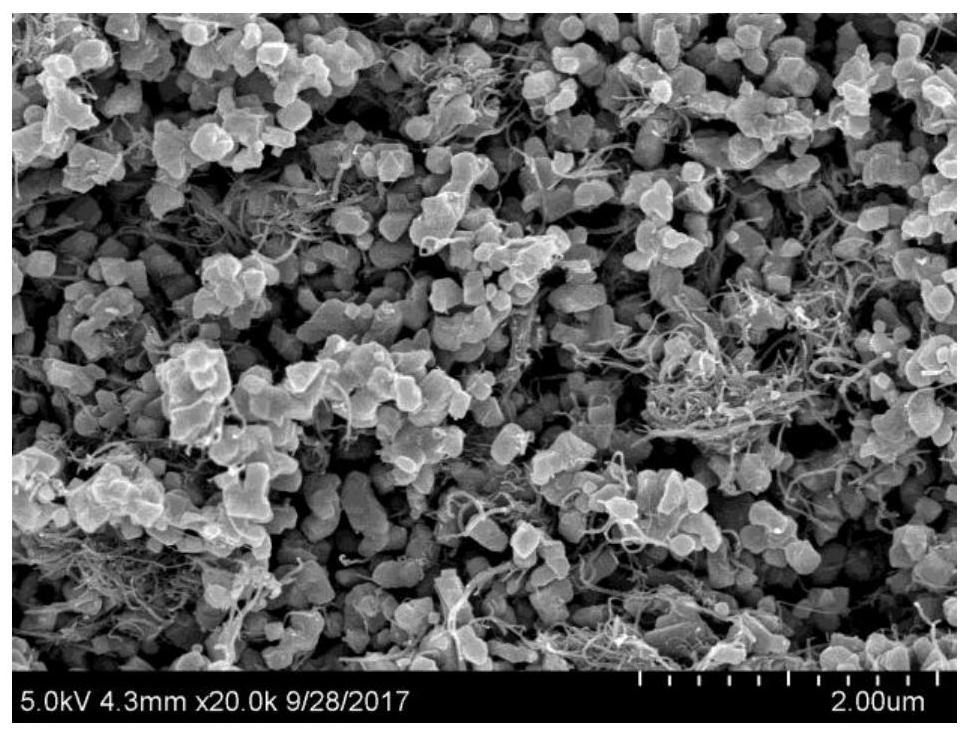

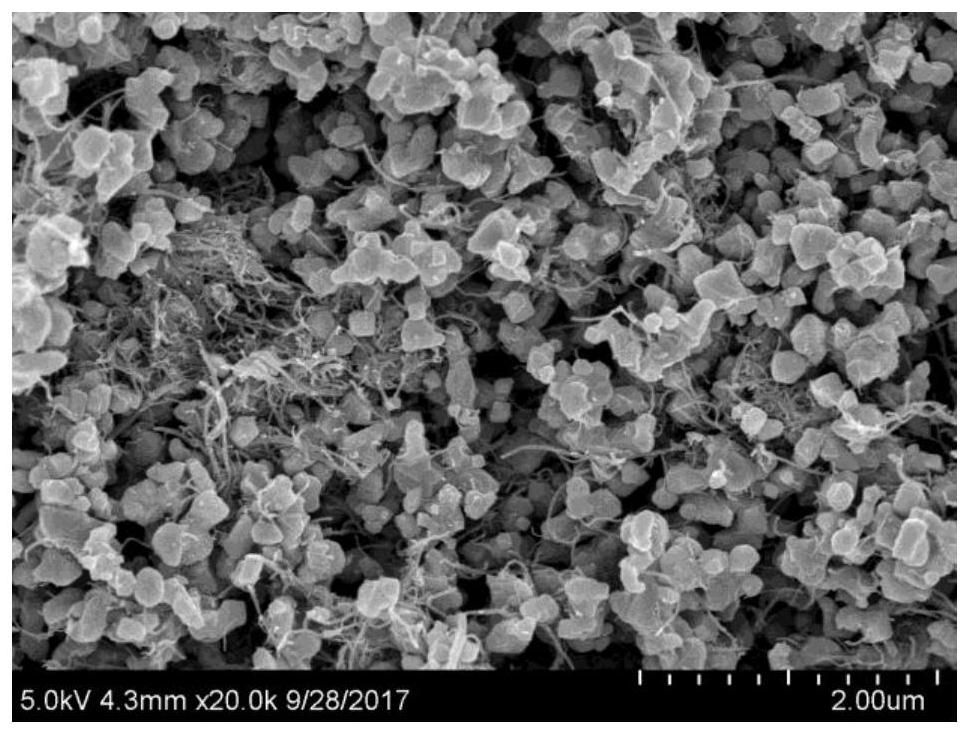

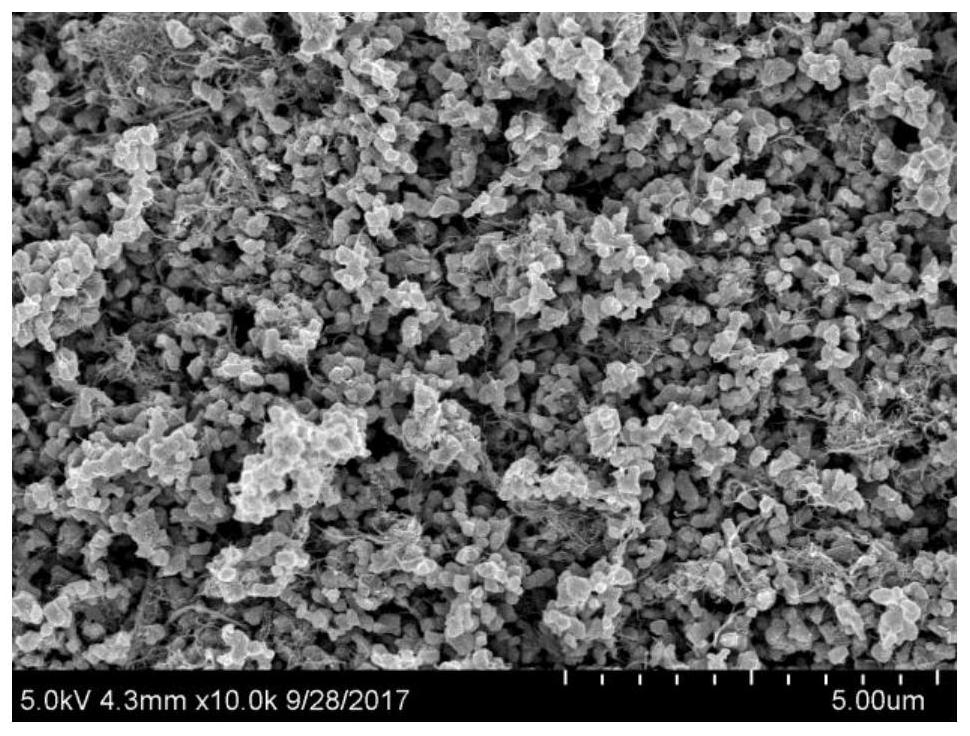

Image

Examples

Embodiment 1

[0030] A preparation method for a tin sulfide composite negative electrode material, comprising the following steps:

[0031] (1) Get stannous sulfide and carbon nanotubes, join them in the sodium alginate aqueous solution, place them in a ball mill, and obtain a uniformly dispersed mixed solution after ball milling;

[0032] (2) adding the above mixed solution dropwise into the metal salt solution, stirring evenly to obtain the hydrogel of the mixed solution;

[0033] (3) Take the hydrogel of the above mixed solution, mix it with the silicon-coated modified precursor, stir evenly, wash, filter, dry, roast, and cool to obtain the stannous sulfide composite negative electrode material.

[0034] The concentration of the sodium alginate aqueous solution is 1 wt%.

[0035] The weight ratio of the stannous sulfide to carbon nanotubes is 1:950.

[0036] The metal salt is ferrous sulfate, and the concentration of the metal salt solution is 3 wt%.

[0037] The silicon-coated modifi...

Embodiment 2

[0045] A preparation method for a tin sulfide composite negative electrode material, comprising the following steps:

[0046] (1) Get stannous sulfide and carbon nanotubes, join them in the sodium alginate aqueous solution, place them in a ball mill, and obtain a uniformly dispersed mixed solution after ball milling;

[0047] (2) adding the above mixed solution dropwise into the metal salt solution, stirring evenly to obtain the hydrogel of the mixed solution;

[0048] (3) Take the hydrogel of the above mixed solution, mix it with the silicon-coated modified precursor, stir evenly, wash, filter, dry, roast, and cool to obtain the stannous sulfide composite negative electrode material.

[0049] The concentration of the sodium alginate aqueous solution is 2wt%.

[0050] The weight ratio of the stannous sulfide to carbon nanotubes is 1:1000.

[0051] The metal salt is one of nickel sulfate, and the concentration of the metal salt solution is 5 wt%.

[0052] The silicon-coated ...

Embodiment 3

[0060] A preparation method for a tin sulfide composite negative electrode material, comprising the following steps:

[0061] (1) Get stannous sulfide and carbon nanotubes, join them in the sodium alginate aqueous solution, place them in a ball mill, and obtain a uniformly dispersed mixed solution after ball milling;

[0062] (2) adding the above mixed solution dropwise into the metal salt solution, stirring evenly to obtain the hydrogel of the mixed solution;

[0063] (3) Take the hydrogel of the above mixed solution, mix it with the silicon-coated modified precursor, stir evenly, wash, filter, dry, roast, and cool to obtain the stannous sulfide composite negative electrode material.

[0064] The concentration of the sodium alginate aqueous solution is 0.5wt%-2wt%.

[0065] The weight ratio of the stannous sulfide to carbon nanotubes is 1:900.

[0066] The metal salt is manganese sulfate, and the concentration of the metal salt solution is 1 wt%.

[0067] The silicon-coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com