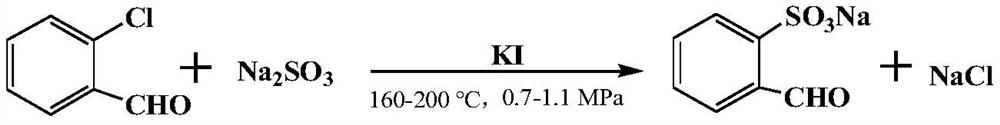

A kind of method for synthesizing o-sulfonic acid benzaldehyde under normal pressure

A technology of o-sulfonic acid benzaldehyde and a synthesis method, applied in the directions of sulfonic acid preparation, sulfonate preparation, organic chemistry, etc., can solve problems such as restricting the industrial production of sodium o-sulfonic acid benzaldehyde, and achieve easy control of industrial production and high yield. The effect of high rate and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

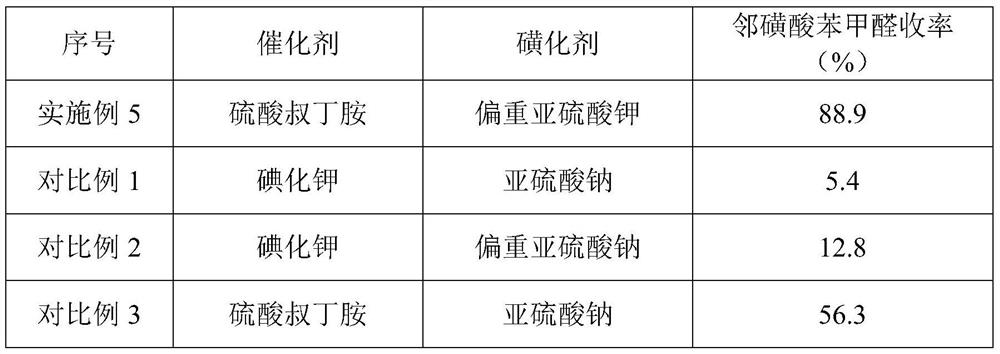

Embodiment 1

[0026] 7g of o-chlorobenzaldehyde (0.05mol) was added to the three-necked flask, 15mL of water and 0.3g of tetrabutylammonium bromide were added successively, the temperature was raised to 60° C., and stirred for 10min. Another 11.67 g of potassium bisulfite (0.0525 mol) was dissolved in 20 mL of water, and the potassium bisulfite solution was added dropwise to the reaction mixture for about 30 minutes. The reaction was carried out at about 70°C for 8h, and the reaction was completed to obtain a pale yellow liquid. The reaction solution was transferred to a beaker, a small amount of dilute hydrochloric acid was added, and the pH was adjusted to 1.0. Let stand, cool, and crystallize. Suction filtration and drying to obtain crude product. Then recrystallize with absolute ethanol to obtain 7.32 g of the finished product of o-sulfonic acid benzaldehyde, needle-like crystals, the measured melting point is 114.0 ° C ~ 115.7 ° C (the literature value is 114.1 ° C ~ 115.4 ° C), the ...

Embodiment 2

[0028] 7g of o-chlorobenzaldehyde (0.05mol) was added to the three-necked flask, 17.5mL of water and 0.5g of tert-butylamine sulfate were added successively, the temperature was raised to 60° C., and stirred for 10min. Another 11.78 g of potassium bisulfite (0.053 mol) was dissolved in 20 mL of water, and the potassium bisulfite solution was added dropwise to the reaction mixture for about 30 minutes. The reaction was carried out at about 70°C for 10h, and the reaction was completed to obtain a pale yellow liquid. The reaction solution was transferred to a beaker, a small amount of dilute hydrochloric acid was added, and the pH was adjusted to 1.0. Let stand, cool, and crystallize. Suction filtration and drying to obtain crude product. Then recrystallize with absolute ethanol to obtain 7.98 g of o-sulfonic acid benzaldehyde finished product, needle-like crystals, the measured melting point is 114.1 ° C ~ 115.0 ° C (the literature value is 114.1 ° C ~ 115.4 ° C), the purity i...

Embodiment 3

[0030] 7g of o-chlorobenzaldehyde (0.05mol) was added to the three-necked flask, 20mL of water and 0.5g of tert-butylamine hydrochloride were added successively, the temperature was raised to 60° C., and stirred for 10min. Another 12.00 g of potassium bisulfite (0.054 mol) was dissolved in 20 mL of water, and the potassium bisulfite solution was added dropwise to the reaction mixture for about 30 minutes. The reaction was carried out at about 70°C for 12h, and the reaction was completed to obtain a pale yellow liquid. The reaction solution was transferred to a beaker, a small amount of dilute hydrochloric acid was added, and the pH was adjusted to 1.0. Let stand, cool, and crystallize. Suction filtration and drying to obtain crude product. Then recrystallize with absolute ethanol to obtain 7.11 g of finished product of o-sulfonic acid benzaldehyde, needle-like crystals, the measured melting point is 113.8 ° C ~ 115.1 ° C (the literature value is 114.1 ° C ~ 115.4 ° C), the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com