Negative bending moment construction hanging basket in a limited space of T-beam middle beam and using method

A limited space, negative bending moment technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult access to construction platforms, construction difficulties, negative bending moment tensioning and grouting operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

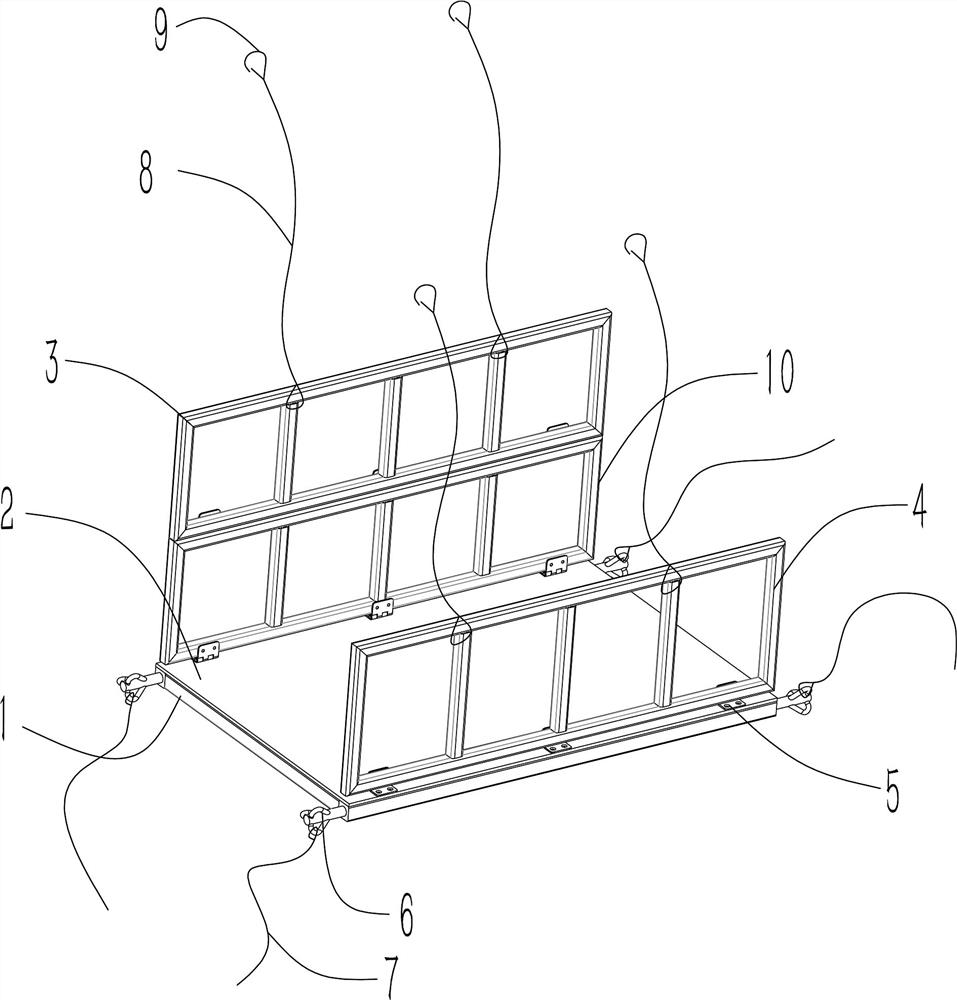

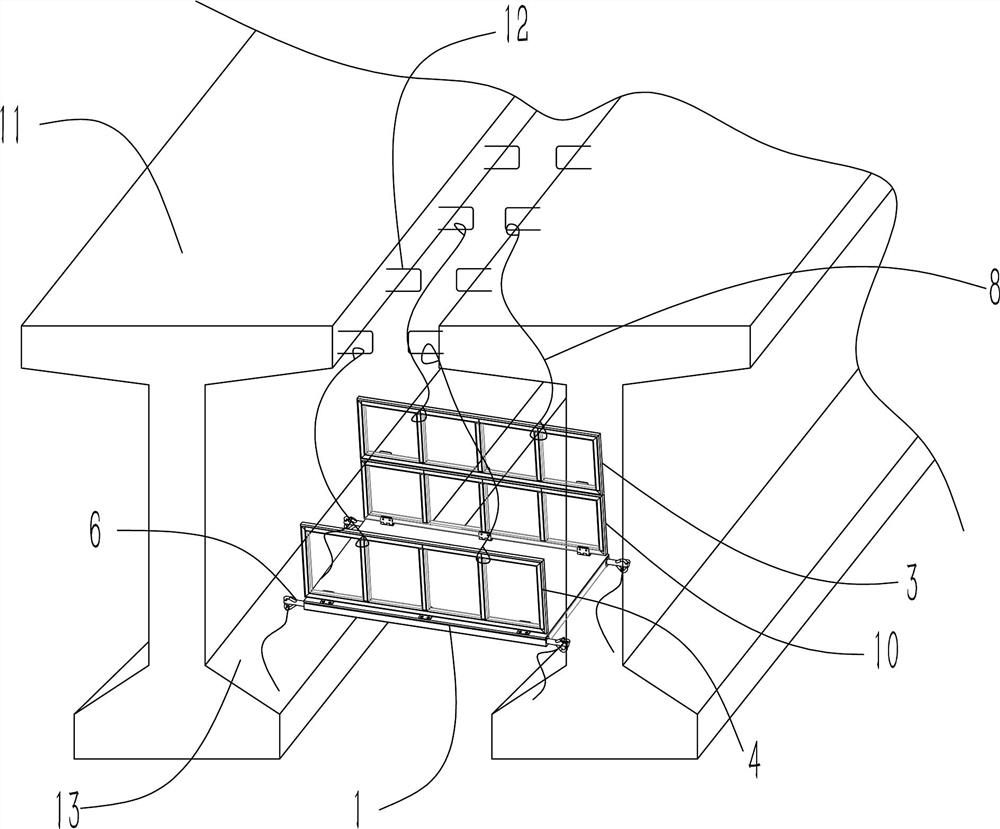

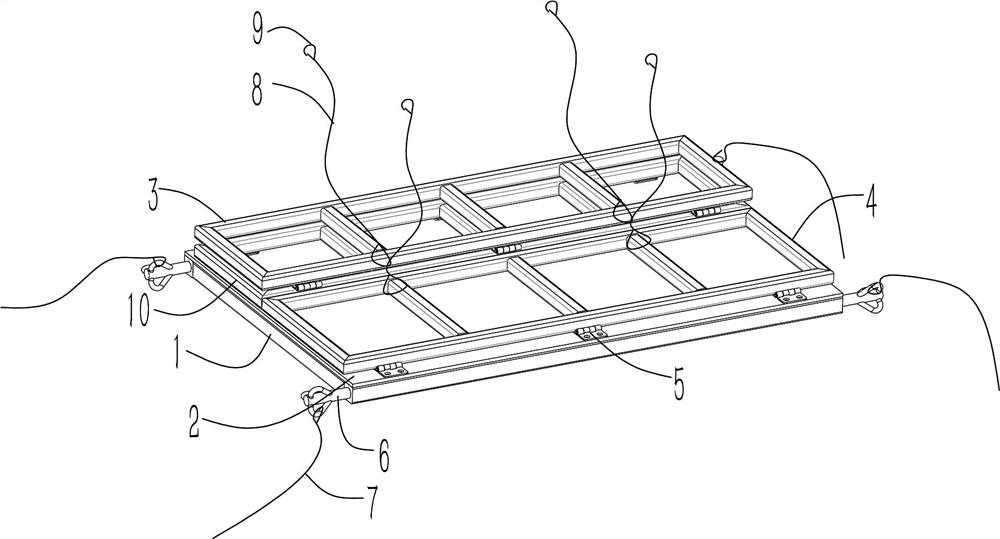

[0026] Such as Figure 1~3 As shown, a negative bending moment construction hanging basket in a limited space in the middle beam of a T beam includes a support base 1, and a plurality of screw rods 6 are arranged on both sides of the support base 1, and the screw rods 6 are threadedly connected with the support base 1, and the support base 1 Both sides above are provided with a foldable third guardrail 10 and a second guardrail 4. The third guardrail 10 and the second guardrail 4 are provided with a plurality of wire ropes 8, and the ends of the wire ropes 8 are provided with hooks 9, thus the structure , supported by the screw rod 6 against the T-beam shoe 13, the steel wire rope 8 is hung on the T-beam hoop 12 through the hook 9, and the lower support and hanging structure ensures the safety of the construction personnel. The foldable third guardrail 10 and the first The second guardrail 4 ensures that the hanging basket can be folded into a narrow space, is suitable for con...

Embodiment 2

[0032] Further illustrate in conjunction with embodiment 1, as Figure 1~3 As shown, determine the distance between the ribs of the two T-beams 11 and the distance between the two beam shoes 13, adjust the screw rod 6 of the hanging basket so that the distance between the screw rods 6 is between the distance between the beam ribs and the distance between the beam shoes 13, so that The hanging basket can be supported on the beam shoe 13, and the upper part is hung on the stirrup 12 of the T-shaped beam 11 through the steel wire rope 8 and the hook 9, and the upper hanging and lower supporting type is adopted to make the whole more stable and the personnel construction safer; use method: personnel Fold the hanging basket guardrail above the T-shaped beam 11, and fix it crosswise with steel wire rope 8 to prevent it from unfolding during the descent. Then adjust the screw rod 6 so that it can be supported by the beam shoe 13. Hang the hanging basket to the working position, put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com