Door stop assembly used for double-door and use method of door stop assembly

A technology for double-leaf doors and doorstops, which is applied in the fields of fastening devices for wings, building fastening devices, construction, etc. It can solve the problems of shortening the service life of double-leaf doors, deformation of the door body or door frame, and large torque of the door frame, etc., to achieve Uniform force, reduce the probability of damage, reduce the effect of torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

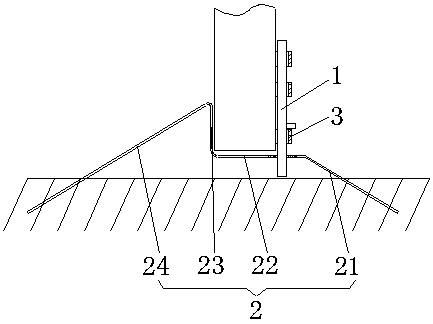

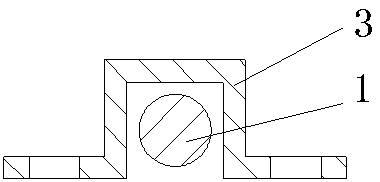

[0023] A doorstop assembly for double doors, as shown in the figure, includes a baffle plate 2 fixed on the ground along the door opening and closing direction, and the baffle plate 2 is sequentially provided with a first inclined surface 21 extending upwards along the door closing direction, and a second inclined surface A flat plane 22 with the end of the inclined plane 21 flush, and a vertical plane 23 extending upward from the end of the plane 22, and a second inclined plane 24 extending downward from the upper end of the vertical plane 23. The plane 22 is lower than the lower edge of the door body, vertically The upper end of the surface 23 is higher than the lower edge of the door body. Parts of the first slope 21 and the second slope 24 are embedded in the ground. Rounded corners are provided at the joints between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com