Chemical equipment dustproofing door

A chemical equipment and dust door technology, applied in the field of chemical equipment dust doors, can solve problems such as dust scattering, health threats, air pollution, etc., and achieve the effect of reducing the probability of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

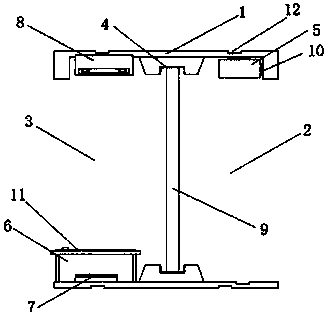

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] A chemical equipment dustproof door, which includes a base frame 1, an isolation layer 2, a filter layer 3, a slide groove 4, an air curtain machine 5, a water storage box 6, an atomizer 7, a mist absorber 8, a movable door 9, Fixed frame 10 and moving plate 11, base frame 1 is used for fixing mobile door 9, and base frame 1 is made of aluminum alloy, and sliding groove 4 is embedded on the protruding piece in the middle of base frame 1, and movable door 9 is installed in sliding groove 4, moves The right side of the door 9 is provided with an isolation layer 2, and the isolation layer 2 is composed of an air curtain machine 5 and a fixed frame 10. The fixed frame 10 is installed on the top of the base frame 1, and the air curtain machine 5 is housed in the fixed frame 10. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com