Corrugated steel segment ring, flexible segment lining and design method of flexible segment lining

A corrugated, segmented technology, used in wellbore lining, tunnel lining, mining equipment, etc., can solve the problem of poor stability, water inrush and mud inrush in shield tunnels, structural damage of segments, and oversized bolts on the joint surface of segments. and other problems, to achieve the effect of good stability and easy compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the embodiments described below are only some, not all, embodiments of the present invention. Without departing from the spirit and scope of the present invention defined and determined by the appended claims, all other embodiments obtained by those skilled in the art without any creative effort shall fall within the protection scope of the present invention.

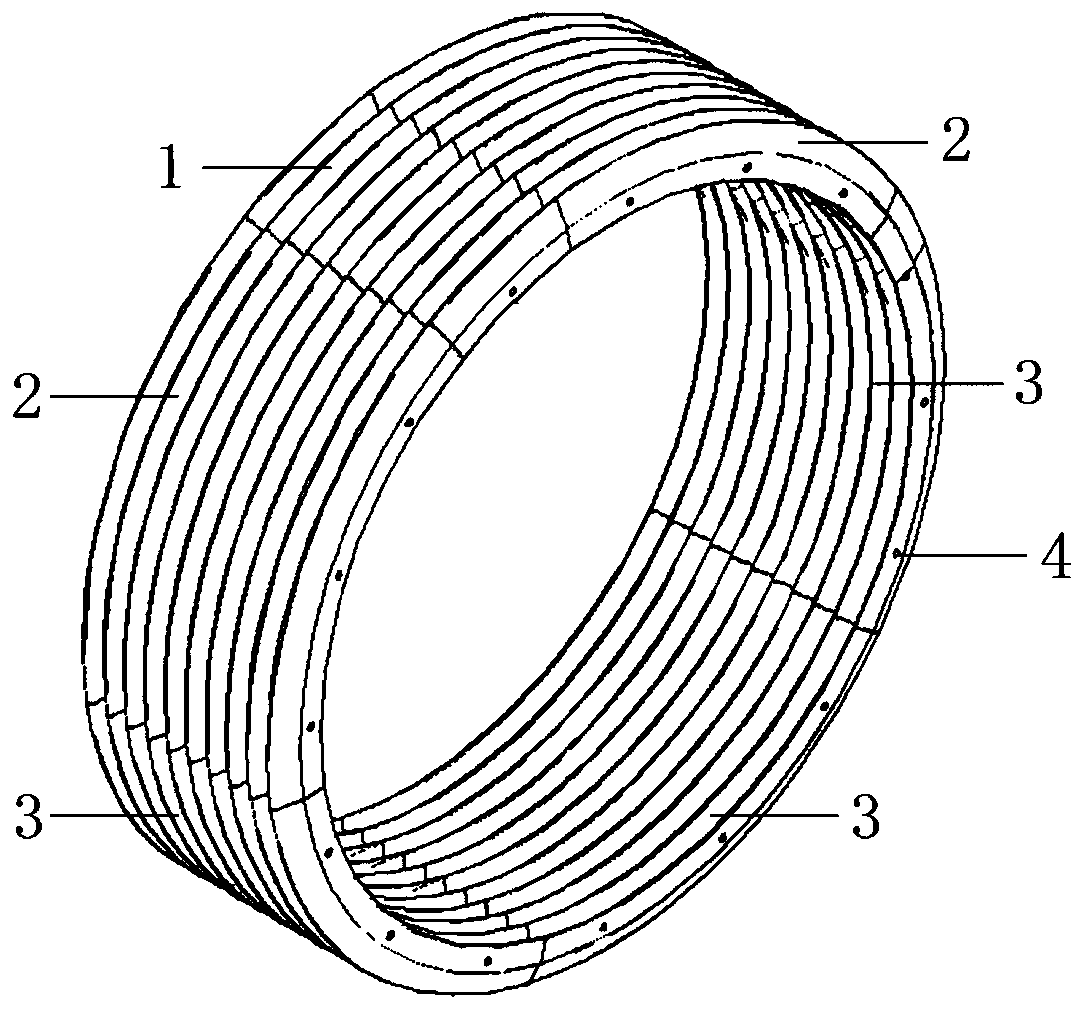

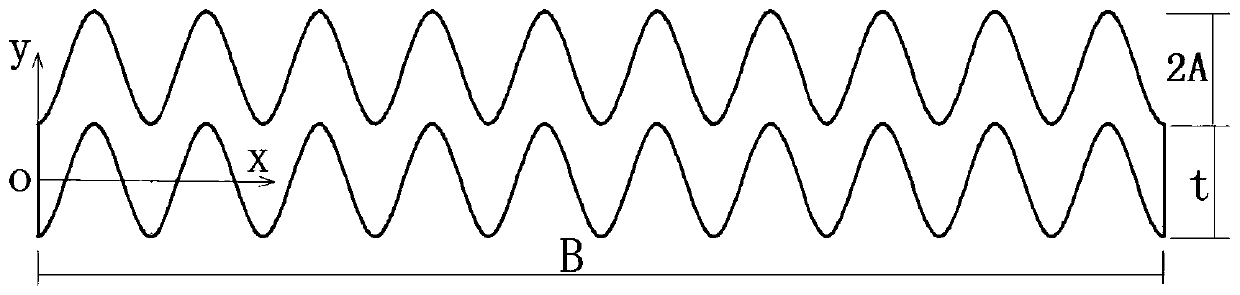

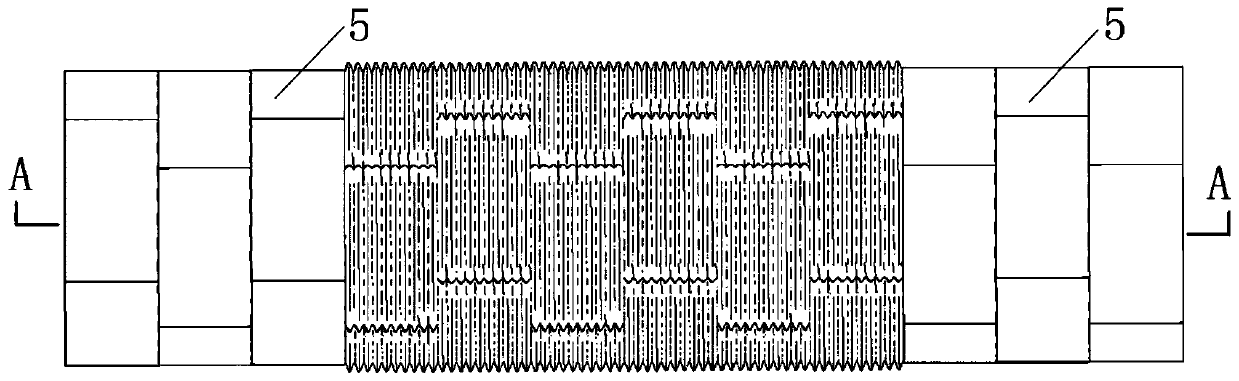

[0034] Such as figure 1 and figure 2 As shown, the corrugated steel pipe sheet ring includes a plurality of ring-shaped segments surrounded by segments, and longitudinal bolt holes 4 and circumferential bolt holes are opened on the segment segments, and the adjacent segments pass through the circumferential bolt holes that match the annular bolt holes. Bolted connection, the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com