Installation detection and error analysis method for guide rail

A technology of error analysis and guide rails, applied in the direction of measuring devices, optical devices, large fixed members, etc., to achieve the effect of strong operability, reasonable conception and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

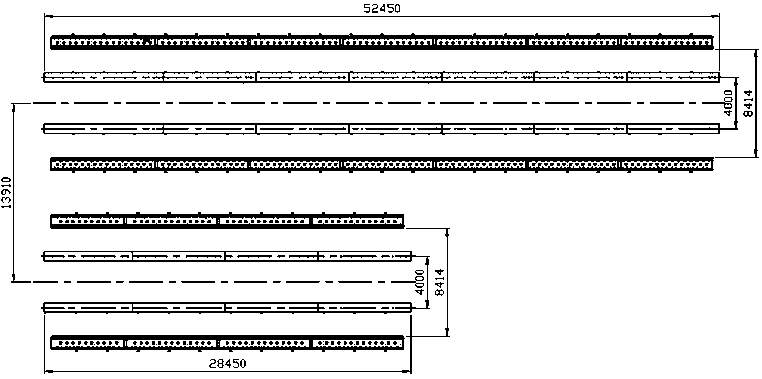

[0037] The installation detection and error analysis method of the guide rail of the present invention refers to a large, super long, space guide rail; the establishment of the guide rail space model firstly establishes various installation references in the processing stage, and these references are also used as adjustments during the installation process. For dynamic observation points, the installation datum is composed of datum plane, datum hole, target bracket, etc.; secondly, the measurement equipment must meet the installation accuracy requirements. The actual state of the guide rail is obtained by measuring the above-mentioned various installation benchmarks, and the least square method is used to fit the guide rails one by one, and compared with the theoretical state to determine whether the straightness, flatness, and verticality meet the requirements.

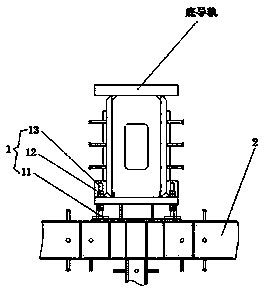

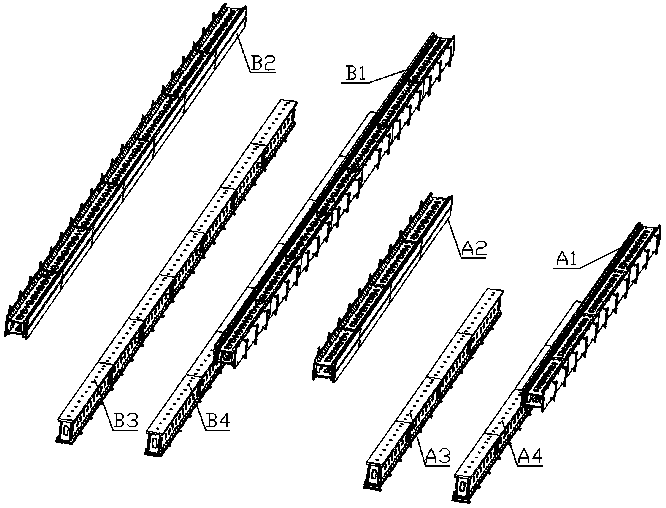

[0038] Such as figure 1 As shown, the guide rails are composed of two groups of long and short guide rails. The gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com