High-frequency vibration system and method for nondestructive testing of microcracks on surface layer of small-size component

A high-frequency vibration, small-scale technology, used in processing the response signal of the probe, material analysis using radiation diffraction, measuring devices, etc., to achieve the effect of facilitating vibration, reducing mass, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] With reference to accompanying drawing, further illustrate the present invention:

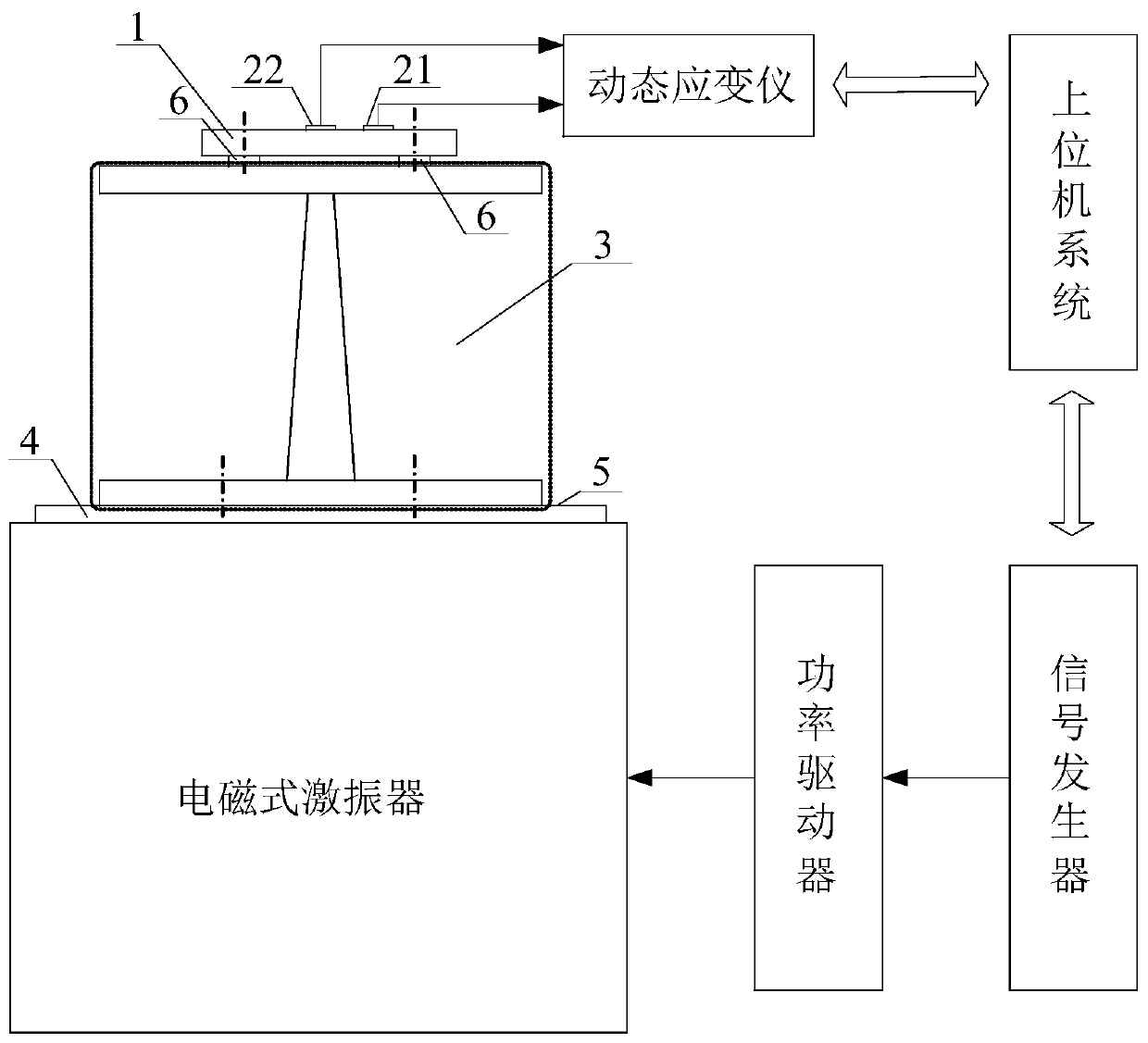

[0036] A high-frequency vibration system for non-destructive detection of microscopic cracks on the surface of small-sized components, including a host computer system, a signal generator, a power driver, an electromagnetic exciter, a high-frequency vibration energy amplification device 3, a pad 6, a strain gauge, and a dynamic Strain gauge; the upper computer system control signal generator outputs a sinusoidal excitation signal whose amplitude and frequency can be independently and continuously adjusted, and is input to the electromagnetic exciter through the power driver;

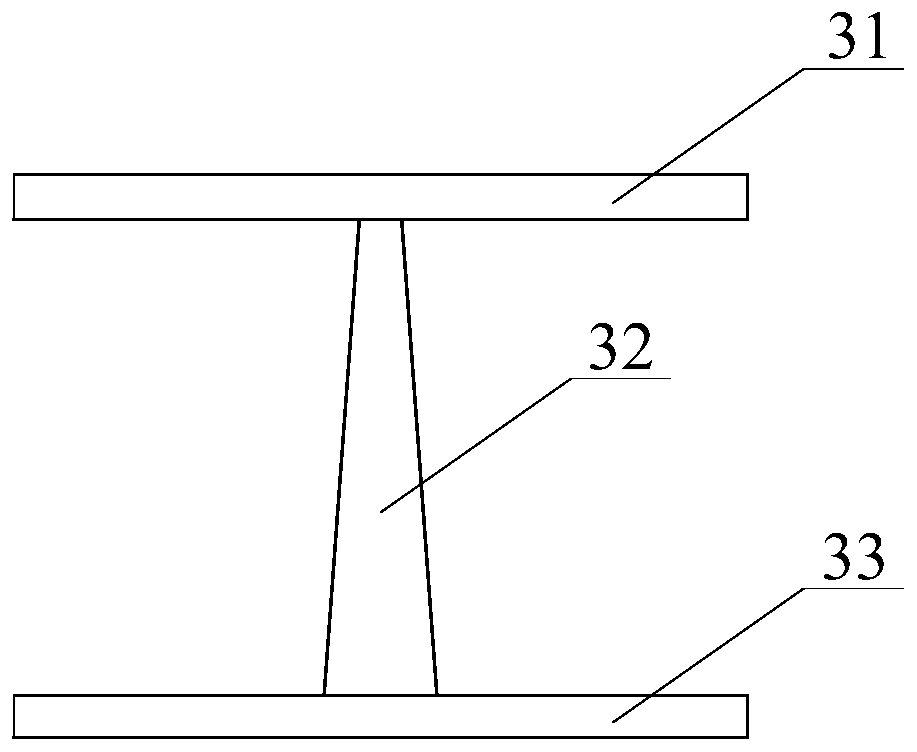

[0037] The high-frequency vibration energy amplifying device 3 is fixed on the excitation table 5 of the moving part 4 of the electromagnetic exciter. The support platform 33 on the excitation table surface 5 of the part 4 and the connecting rod 32 of the circular platform form connecting the workbench 31 and the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap