Automatic heat-dissipation and moisture-proof power distribution cabinet installation box

A technology for power distribution cabinets and installation boxes, which is applied to the substation/power distribution device shell, electrical components, substation/switch layout details, etc., and can solve the problems that the power distribution cabinet does not have heat dissipation and moisture resistance, and the power distribution cabinet is prone to failure, etc. , to achieve the effect of easy promotion, simple structure and moisture prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

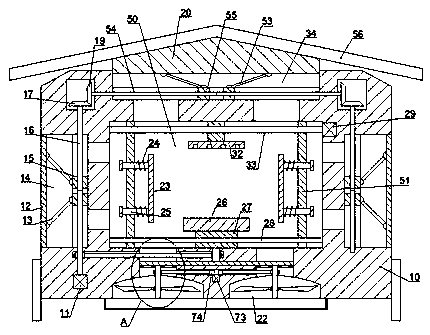

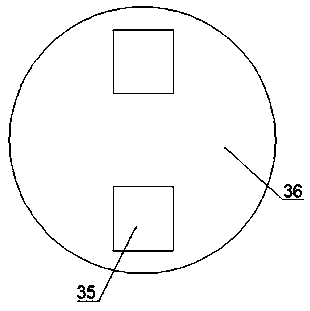

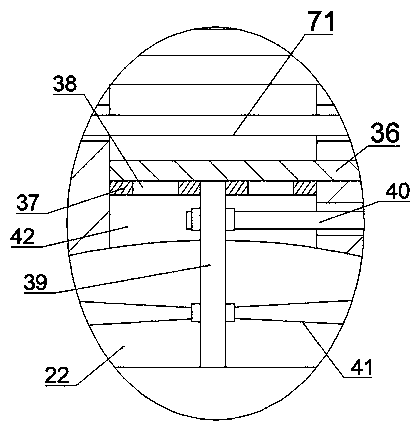

[0014] Combine below Figure 1-3 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0015] refer to Figure 1-3 According to an embodiment of the present invention, an automatic heat dissipation and moisture-proof power distribution cabinet installation box includes a main box body 10, and an installation cavity 50 is opened in the main box body 10, and two slidingly arranged in the installation cavity 50 A set of left and right symmetrical slide plates 51, two groups of slide plates 51 are provided with splints 23 for sliding on the sides close to each other, and the splints 23 are used to clamp the power distribution cabinet. Fixed block 27, a row of rollers 26 are rotated on the top surface of said fixed block 27, side cavities 14 are provided on the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com