Feeding tank convenient in fixed-time and fixed-quantity feed feeding and used for laying hen cultivation

A timing and quantitative feeding technology, which is applied in the field of laying hen breeding, can solve problems such as death, malnutrition of young chicks, and influence on the breeding environment, and achieve the effects of reducing noise pollution, avoiding death of young chicks, and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

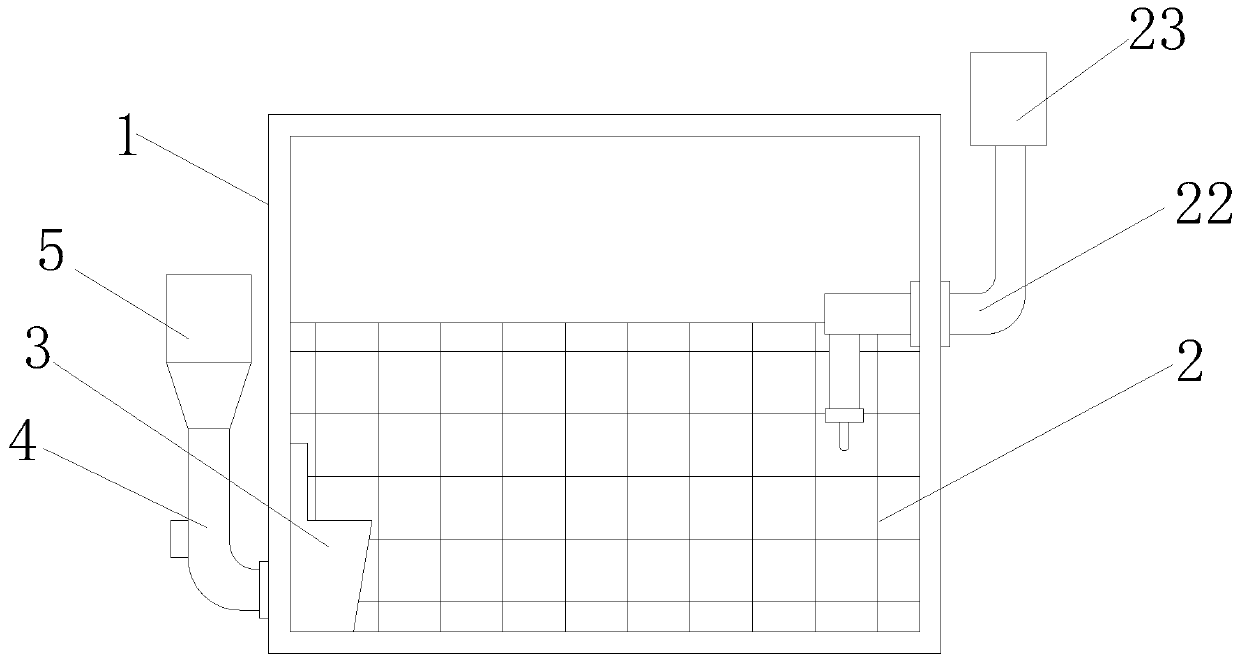

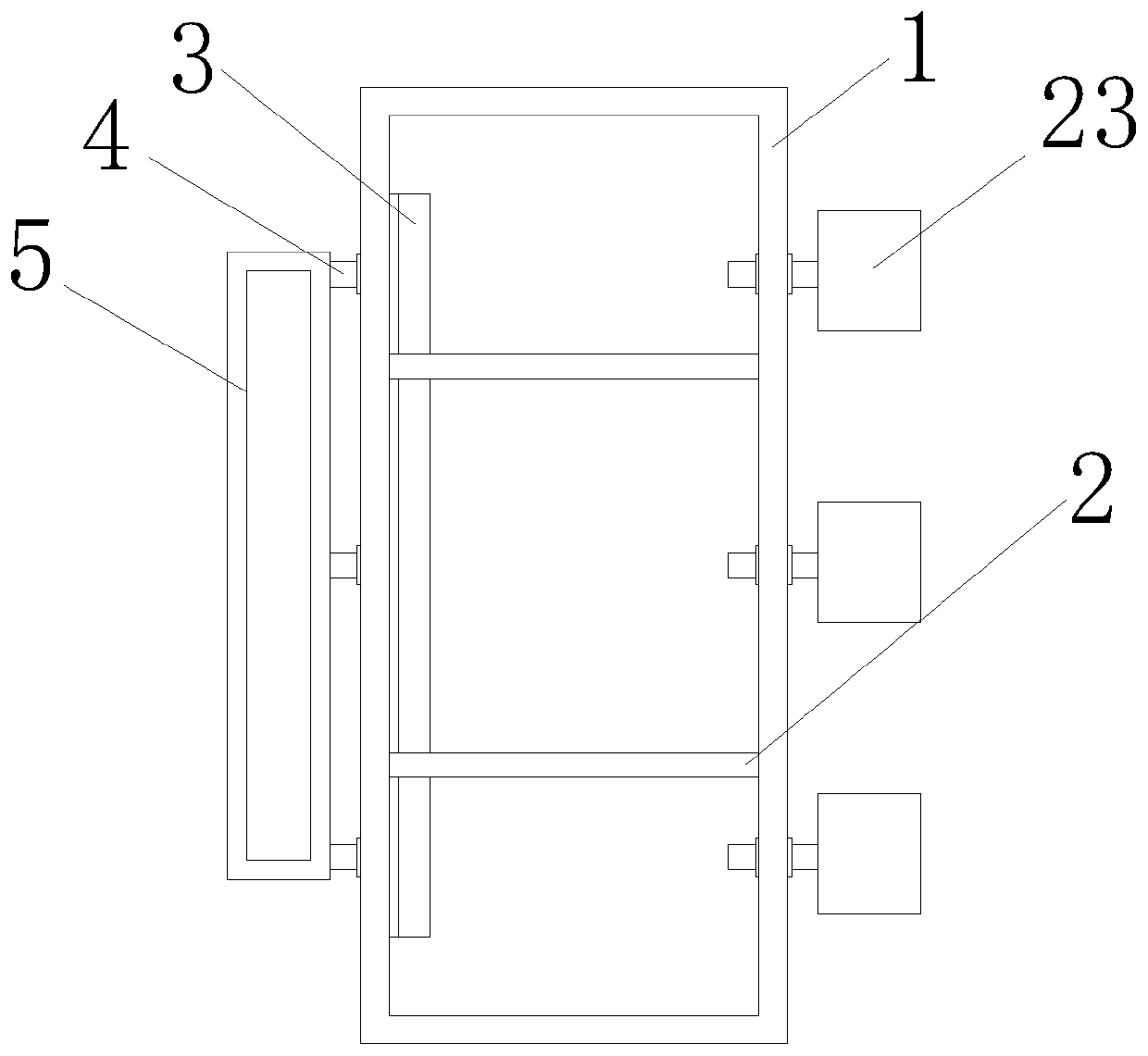

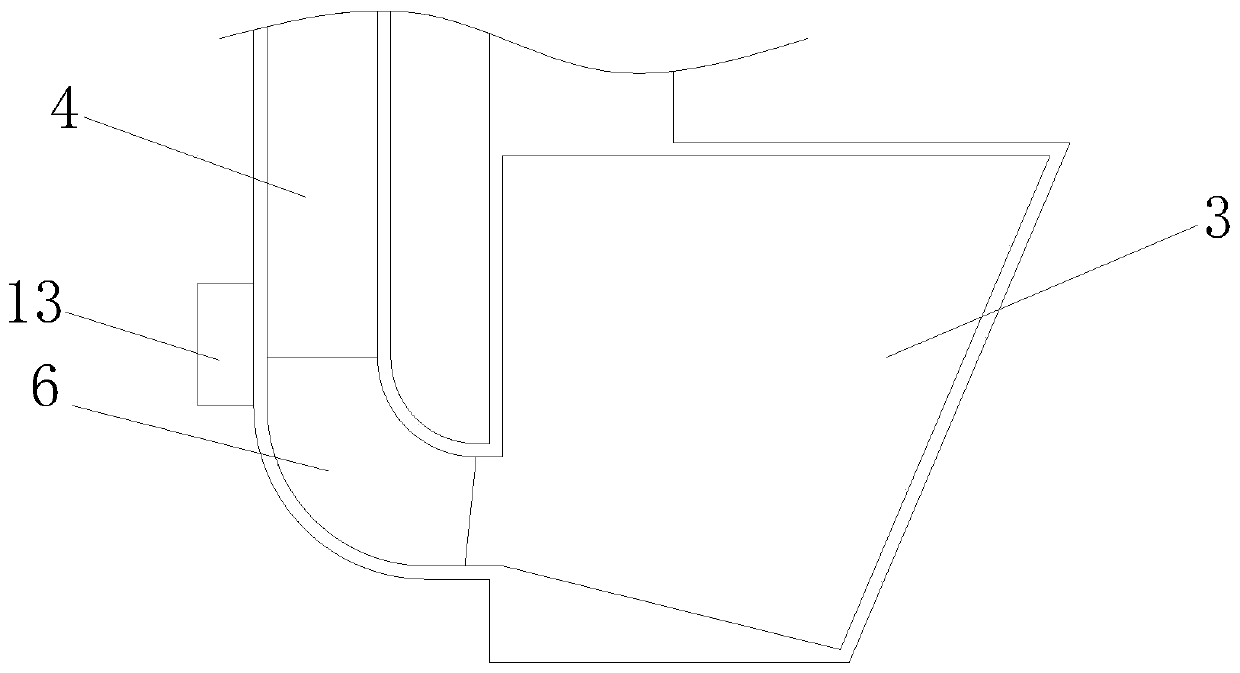

[0025] Example 1, such as Figure 3-4 , 6-7, through the control of the external control device, the drive motor 12 rotates, the rotation of the output end of the motor 12 drives the third gear 11, and the second gear is driven by the meshing effect between the third gear 11 and the second gear 10 10 rotates, and then utilizes the meshing effect between the second gear 10 and the first gear 9 to drive the first gear 9 to rotate and drive the second sieve plate 8 to rotate, when the opening on the second sieve plate 8 and the first sieve plate After the through holes on the 7 are overlapped, the quantitative cylinder 6 is connected with the material storage tank 5, and the feeding is started. When feeding, because the inside of the first sieve plate 7 has five openings, they are arranged in a straight line and straight in length. Rectangular through-hole groups with a width of one centimeter, so the amount of feed passing through the first sieve plate 7 per unit time is constan...

Embodiment 2

[0026] Example 2, such as Figure 4-5 , after feeding for a certain period of time, the second sieve plate 8 is driven to rotate and stop feeding through the rotation of the motor 12 again. Push the connecting rod 15 to move inside the dosing cylinder 6, and while the connecting rod 15 moves, the first sleeve 16 and the second sleeve 18, under the action of the first spring 17 and the second spring 19, move the inside of the dosing cylinder 6 The feed is pushed into the trough 3, because the first tube cover 16 and the second tube cover 18 are connected by a spring, so when the connecting rod 15 moves, the first tube cover 16 and the second tube cover 18 can be quantitatively The inside of the cylinder 6 is stretched in real time, while the connecting rod 15 runs through the side wall of the dosing cylinder 6 and extends to the inside of the dosing cylinder 6. The extension line of the connecting rod 15 is parallel to the tangent line of the inner arc of the dosing cylinder 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com