Continuous sand blasting tool

A technology for sand flushing and tools, applied in the field of continuous sand flushing tools, can solve problems such as pump stoppage, and achieve the effects of improving sand flushing efficiency, avoiding sand blockage, and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

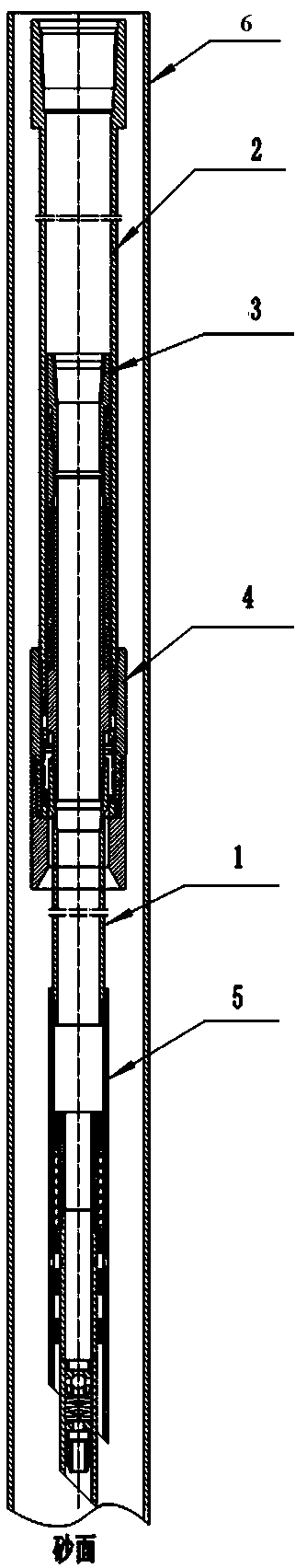

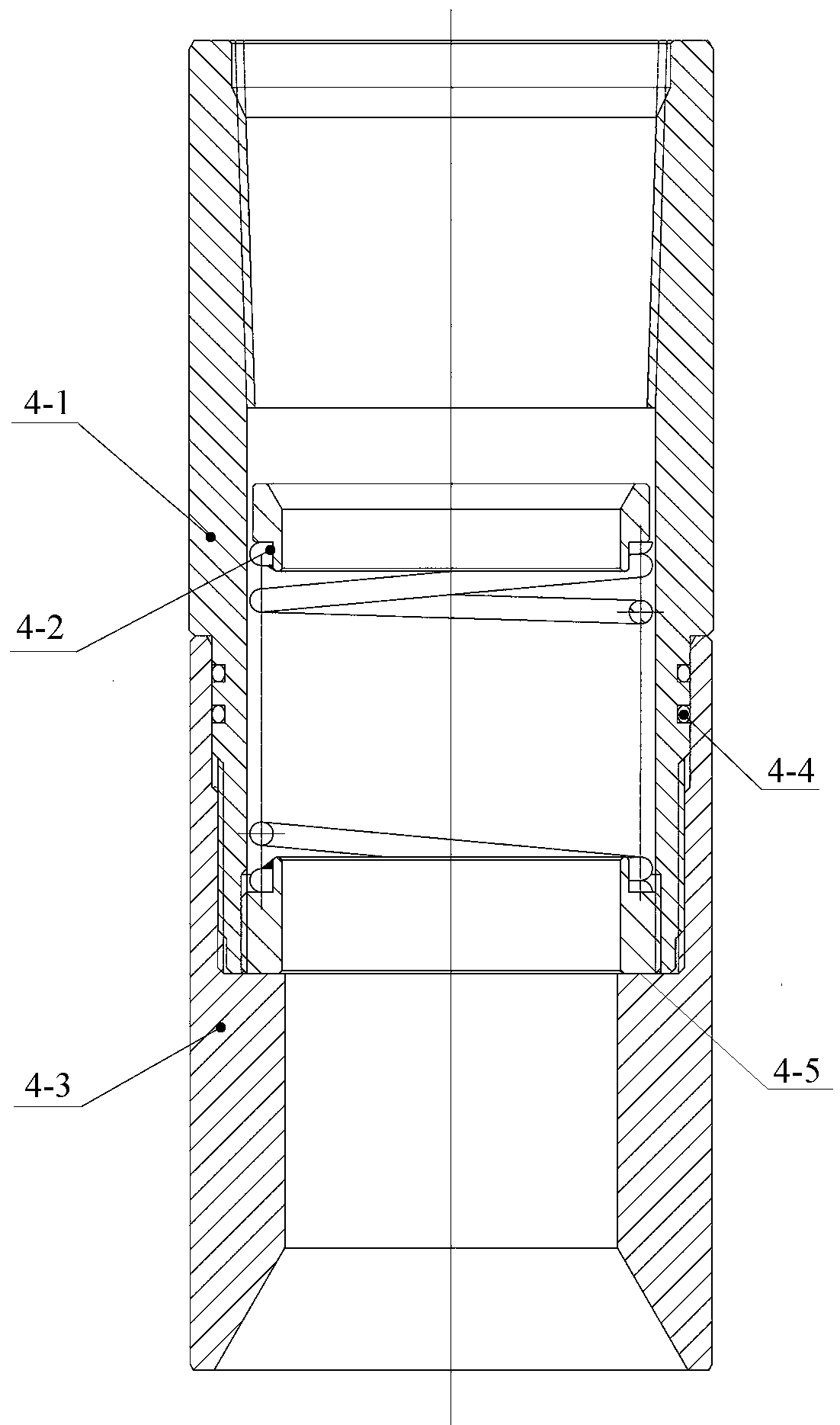

[0016] See Figure 1-Figure 4 , the specific structure of this embodiment is a continuous sand washing tool, including an inner oil pipe 1 (1.900” oil pipe), an outer oil pipe (22-7 / 8” oil pipe), and the inner oil pipe 1 and the outer oil pipe 2 are arranged on the casing 6 Inside, the upper end of the internal oil pipe 1 is provided with a compensation type sand washing sealing tool 3, the lower end of the outer oil pipe 2 is provided with a buffer type sand washing suspension tool 4, and the lower end of the inner oil pipe 1 is provided with a seated strong jet sand washing tool 5;

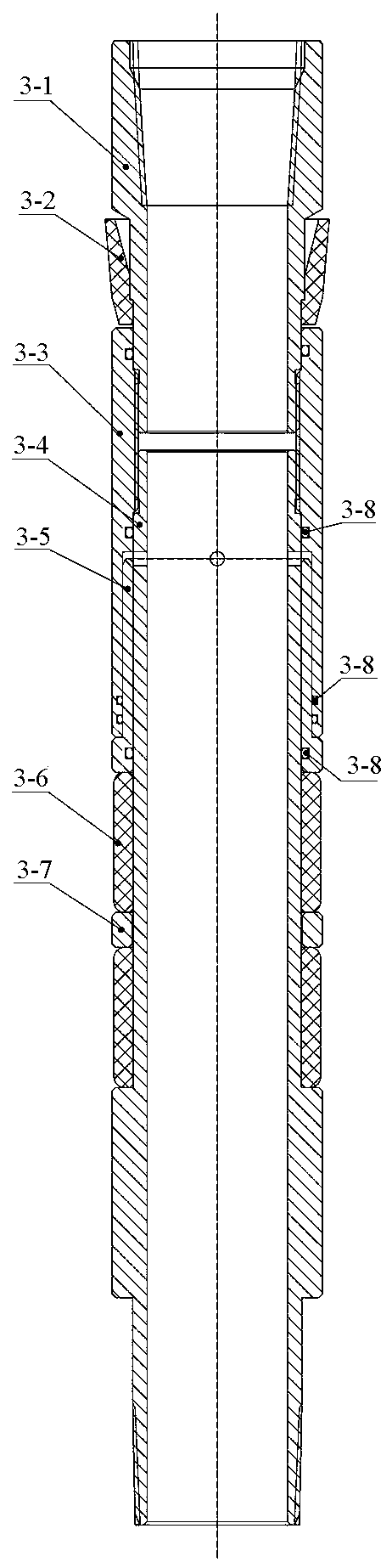

[0017] The compensation type sand flushing sealing tool 3 includes an upper joint I3-1, a center pipe 3-4, a piston 3-5, a sealing sleeve 3-3, and a screw thread is used between the upper joint I3-1 and the center pipe 3-4. Connection, there is a leather cup 3-2 between the upper joint Ⅰ3-1 and the sealing sleeve 3-3, the piston 3-5 slides freely on the central tube, the upper part of the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com