A kind of anti-immersion equipment for automobile exhaust pipe

A technology for automobile exhaust and water immersion prevention, applied in mechanical equipment, exhaust devices, machines/engines, etc., can solve problems such as difficulty in isolating external impurities, and automobile exhaust system cannot isolate floods, etc., to achieve a good operating environment and good waterproof effect , Improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

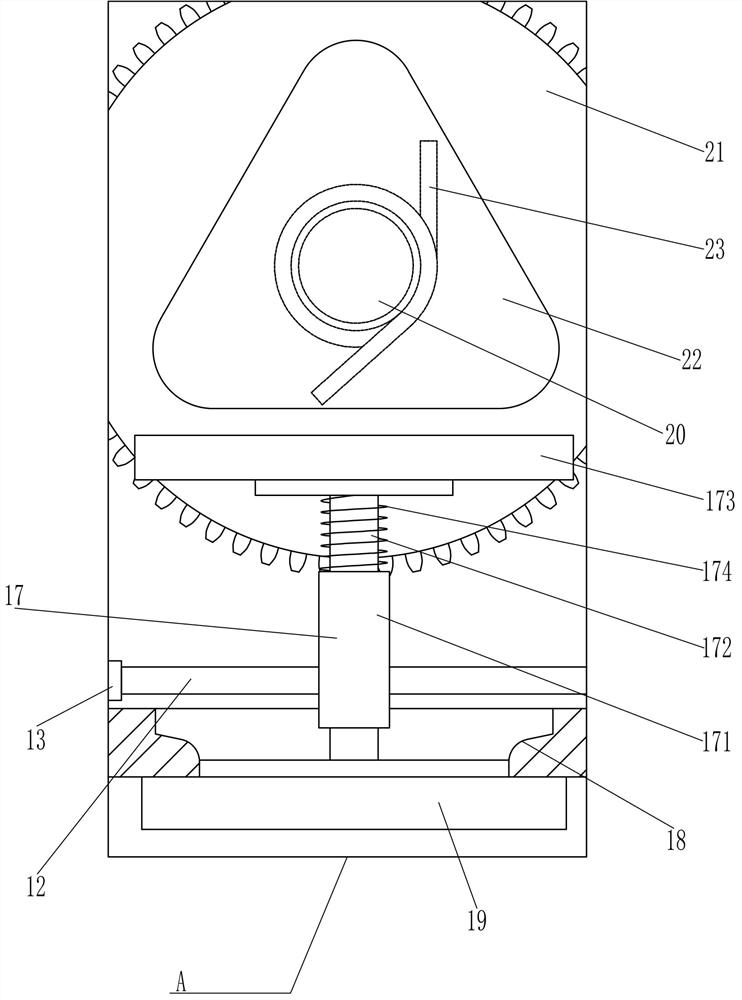

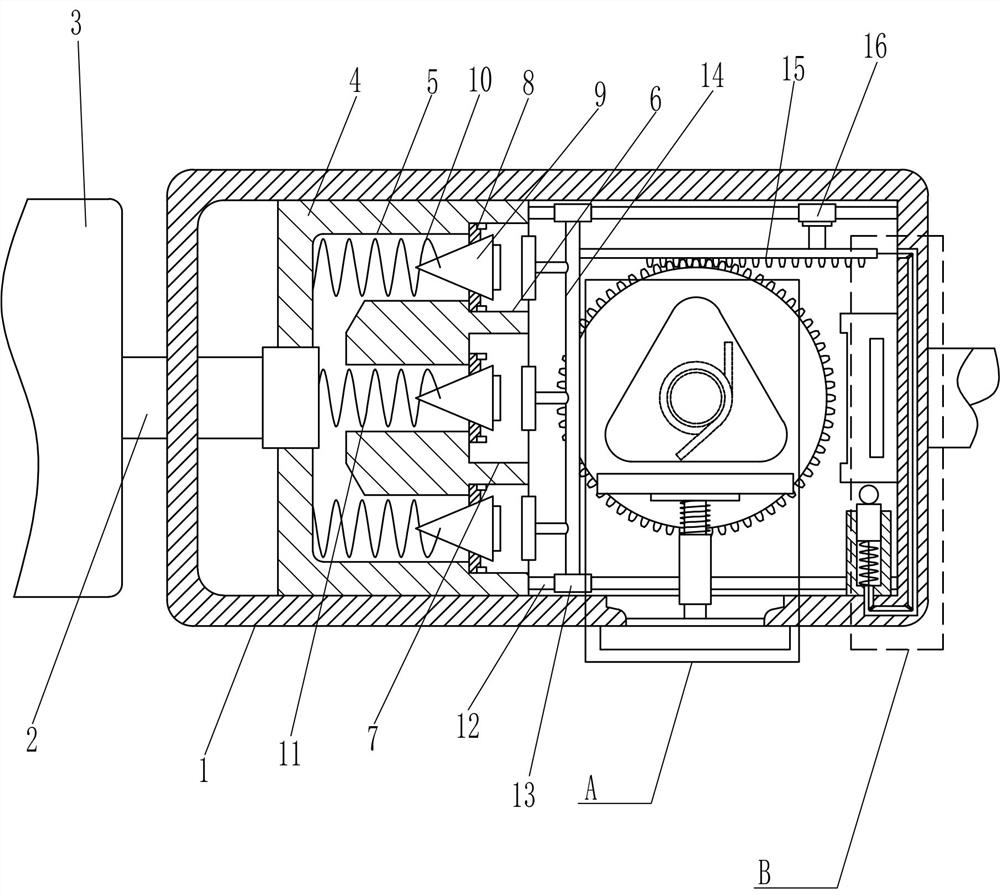

[0021] A kind of automobile exhaust pipe anti-immersion equipment, such as figure 1 and figure 2 As shown, it includes installation box 1, first exhaust pipe 2, installation block 4, ferrule 8, wedge block 9, first compression spring 10, second compression spring 11, guide rod 12, guide sleeve 13, support frame 14. Rack 15, guide frame 16, opening and closing device 17, baffle plate 19, rotating shaft 20, gear 21, cam 22, torsion spring 23, runner 24, filter cover 25 and second exhaust pipe 251, installation box 1 The left side is provided with a first exhaust pipe 2, the left end of the first exhaust pipe 2 is connected to the automobile muffler 3, the right end of the first exhaust pipe 2 is connected with a mounting block 4, and the mounting block 4 is located on the left side of the installation box 1. There is a first cavity 5 in the block 4, a first groove 6 is opened up and down on the right side of the installation block 4, the first groove 6 is connected with the up...

Embodiment 2

[0025] On the basis of Example 1, such as image 3 Shown, also comprise guide wheel 27, backguy 28, perforated concave plate 29, warhead 30 and the 4th compression spring 31, the bottom right side in installation box 1 is provided with perforated concave plate 29, installation box 1 right wall A second cavity 26 is opened, the second cavity 26 is connected with the perforated concave plate 29, the second cavity 26 is provided with a guide wheel 27, the right end of the rack 15 is connected with a pull wire 28, and the pull wire 28 enters the second cavity In the body 26, each guide wheel 27 is bypassed in turn, and then passes through the perforated concave plate 29, and the end is connected with a bullet 30, and the bullet 30 is slidably connected with the perforated concave plate 29, and the bottom end of the bullet 30 is connected with a fourth compression The spring 31, the bottom end of the fourth compression spring 31 is connected with the inner bottom end of the perfora...

Embodiment 3

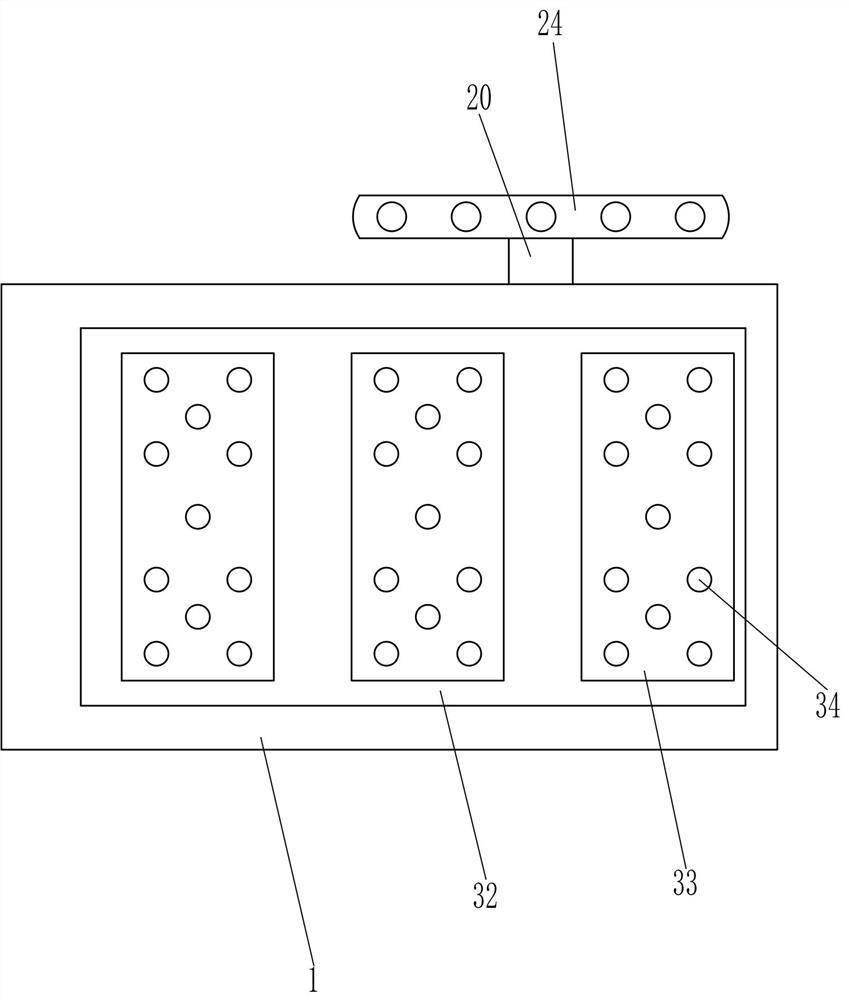

[0028] On the basis of Example 2, such as Figure 4 As shown, it also includes a heat conduction plate 32 and a heat dissipation plate 33. The top of the installation box 1 is provided with a heat conduction plate 32, and the top of the heat conduction plate 32 is provided with a plurality of heat dissipation plates 33, and the heat dissipation plates 33 are all provided with a plurality of heat dissipation holes 34.

[0029] When the equipment is in operation, the heat of the exhaust gas is transferred to the heat dissipation plate 33 through the heat conduction plate 32, and through the heat dissipation holes 34 on the heat dissipation plate 33, the contact area between the heat dissipation plate 33 and the air is increased, and the heat dissipation capacity of the equipment is improved. Provides a good operating environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com