AGV test structure, walk test method and trolley

A technology for testing structure and testing mechanism, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the difficulty in reflecting the movement speed and travel distance of AGV trolleys, the actual movement of AGV trolleys, and the difficulty in transformation. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

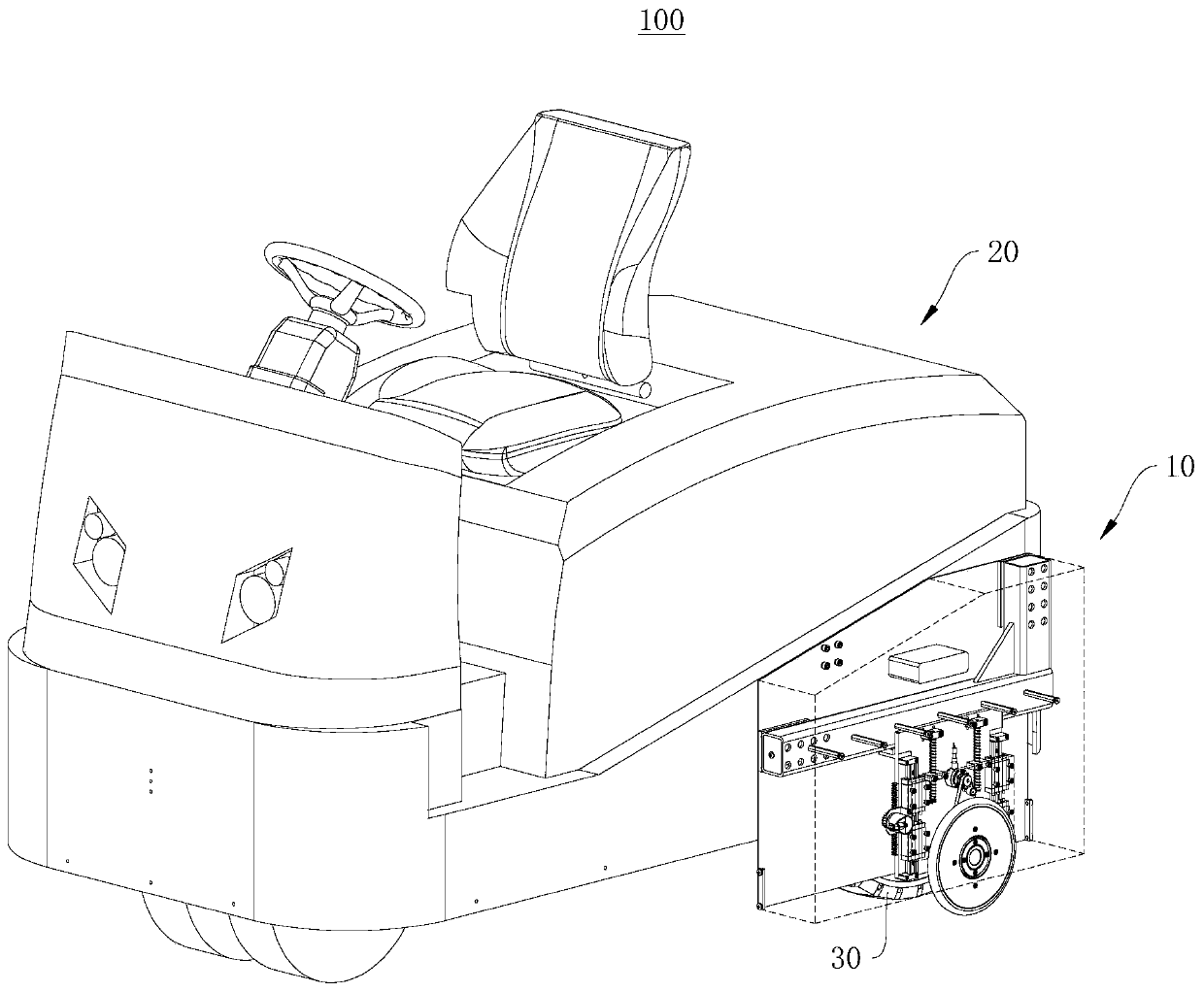

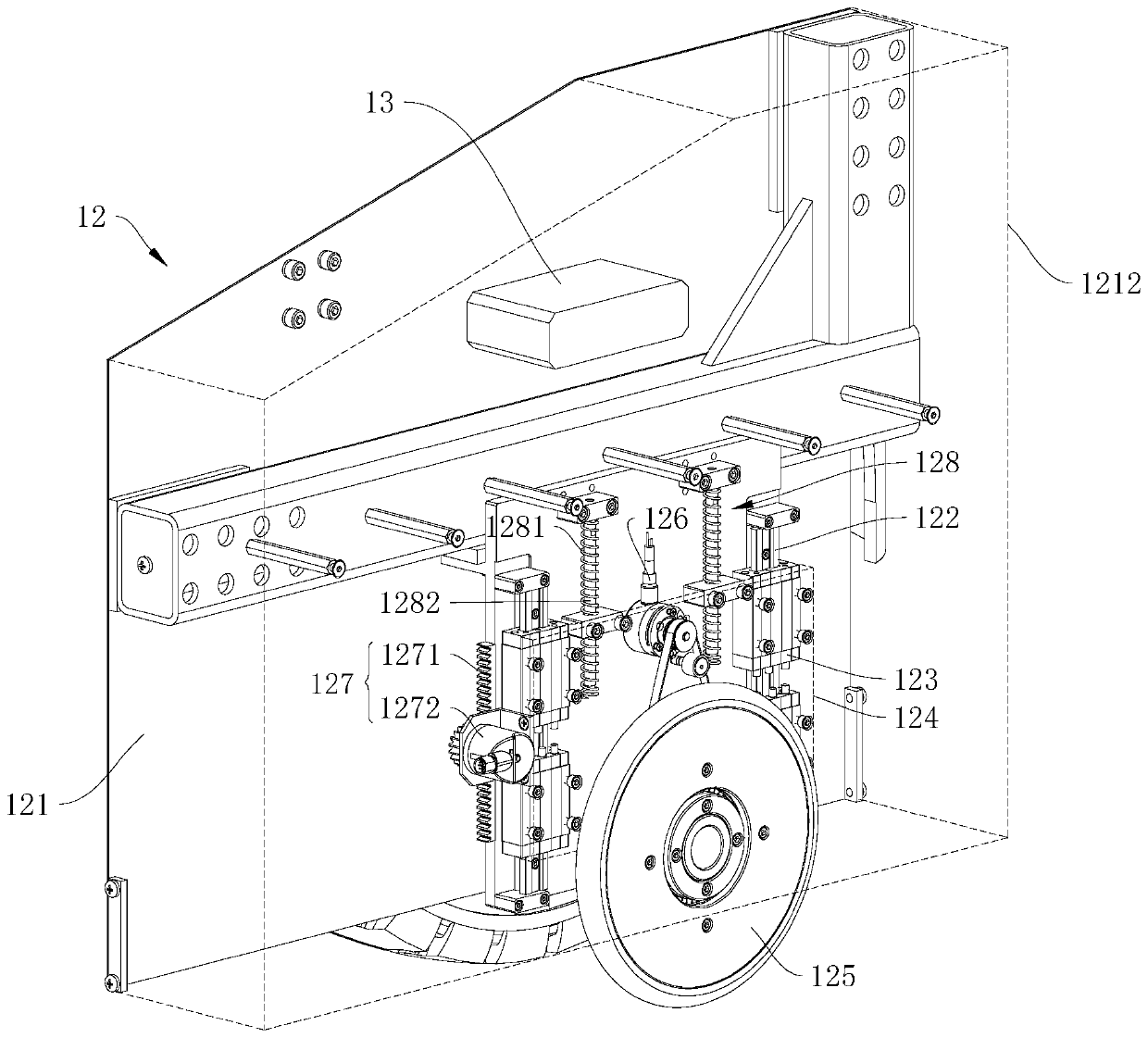

[0032] see figure 1 , figure 1 A schematic diagram of the structure of the AGV test structure 10 applied to the AGV trolley 100 provided by the first embodiment of the present invention. Wherein, for the convenience of display, the installation cover 1212 and the sliding plate 124 of the AGV test structure 10 are treated in perspective, and are represented by dotted lines.

[0033] The first embodiment of the present invention provides an AGV test structure 10 , the data tested by the AGV test structure 10 can more truly reflect the motion of the AGV trolley 100 . The AGV test structure 10 can be applied to an AGV trolley 100 and a tractor.

[0034] Wherein, taking the AGV test structure 10 applied to the AGV trolley 100 as an example, the AGV trolley 100 includes the above-mentioned AGV test structure 10 to test the movement of the AGV trolley 100 through the AGV test structure 10. Of course, the AGV trolley 100 can also include The trolley main body 20 and the wheels 30, ...

no. 2 example

[0060] see image 3 , image 3 It is a schematic flowchart of the AGV walking test method provided by the second embodiment of the present invention.

[0061] It should be noted that the AGV walking test method provided in the second embodiment of the present invention is applied to the AGV test structure 10 in the first embodiment, the basic principle and the technical effect produced are roughly the same as those of the above-mentioned embodiment, and are briefly described For parts not mentioned in this embodiment, reference may be made to the corresponding content in the foregoing embodiments.

[0062] The AGV walking test method is used to test the movement of the AGV trolley 100, and the test method includes:

[0063] Step S101: Calculate the moving speed or moving distance of the AGV trolley 100 according to the rotation data and sliding data.

[0064] For example: when the wheel 30 crosses a pit or a raised obstacle, and the corresponding test wheel 125 rolls on a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com