Anti-collision power distribution cabinet convenient to move

A power distribution cabinet and anti-collision technology, which is applied in the substation/power distribution device shell, electrical components, animal repellent, etc., can solve the problem that the distance between the installation boards of the power distribution cabinet cannot be adjusted, and the cabinet body is easily polluted by bird droppings, etc. problem, to achieve the effect of solving the non-adjustable spacing and avoiding bird droppings pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

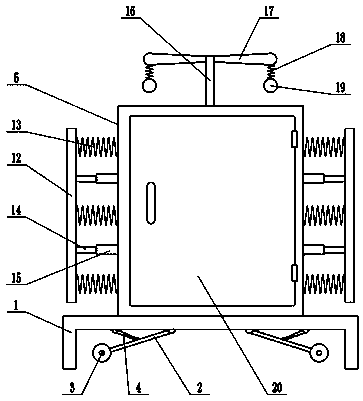

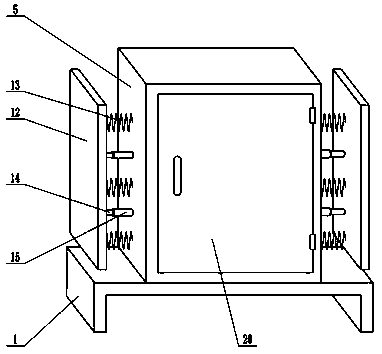

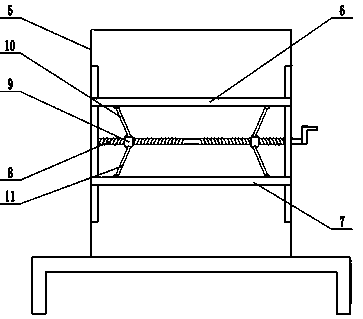

Embodiment 1

[0020] see Figure 1-3 , in the embodiment of the present invention, an anti-collision power distribution cabinet that is easy to move includes a mounting frame 1, a cabinet body 5, an upper mounting plate 6, a lower mounting plate 7 and a cabinet door 20, and the upper surface of the mounting frame 1 is fixedly connected with The cabinet body 5 is equipped with an upper mounting plate 6 and a lower mounting plate 7 inside the cabinet body 5. The electronic components are installed on the upper mounting plate 6 and the lower mounting plate 7. The upper mounting plate 6 and the lower mounting plate 7 are installed horizontally. The ends of the plate 6 and the lower mounting plate 7 are slidingly connected with the inner wall of the cabinet body 5 respectively, the upper mounting plate 6 and the lower mounting plate 7 can slide up and down along the inner wall of the cabinet body 5, and the upper mounting plate 6 and the lower mounting plate 7 Two-way screw rod 8 is installed be...

Embodiment 2

[0022] On the basis of Embodiment 1, the lower surface of the mounting bracket 1 is hinged with a movable rod 2, and there are two movable rods 2, which are arranged symmetrically on the left and right. There are rollers, the lower surface of the mounting frame 1 is hinged with a telescopic mechanism 4, the telescopic mechanism 4 is an electro-hydraulic telescopic cylinder, the lower end of the telescopic mechanism 4 is hinged with the middle part of the movable rod 2, and the extension of the telescopic mechanism 4 is controlled to drive the movable rod 2 to rotate , thereby driving the roller 3 to move downward, so that the roller meets the ground, at this time, the device can be conveniently pushed to move the position.

Embodiment 1、 Embodiment 2

[0023] In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: when it is necessary to install electronic components on the upper mounting plate 6 and the lower mounting plate 7, turn the handle to drive the two-way screw rod 8 to rotate, thereby driving the two sliders 9 Make opposite movement or backward movement, thereby driving the upper mounting plate 6 and the lower mounting plate 7 to move up and down, so as to adjust the distance between the upper mounting plate 6 and the lower mounting plate 7 according to the actual installation requirements, so as to facilitate the installation of electronic components. When the anti-collision plate 12 is impacted, the buffer spring 13 is compressed, which can absorb a part of the energy of the impact, and the buffer spring 13 can play the role of anti-collision, thereby protecting the cabinet body 5 from damage. When the wind blows, the fan blade 17 rotates , to drive the bell 19 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com