N-MOS and P-MOS permanent magnet synchronous motor driving circuit with hardware protection

A permanent magnet synchronous motor and drive circuit technology, applied in motor control, AC motor control, electrical components, etc., to achieve the effects of saving IO resources, improving reliability, and reducing operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the drawings.

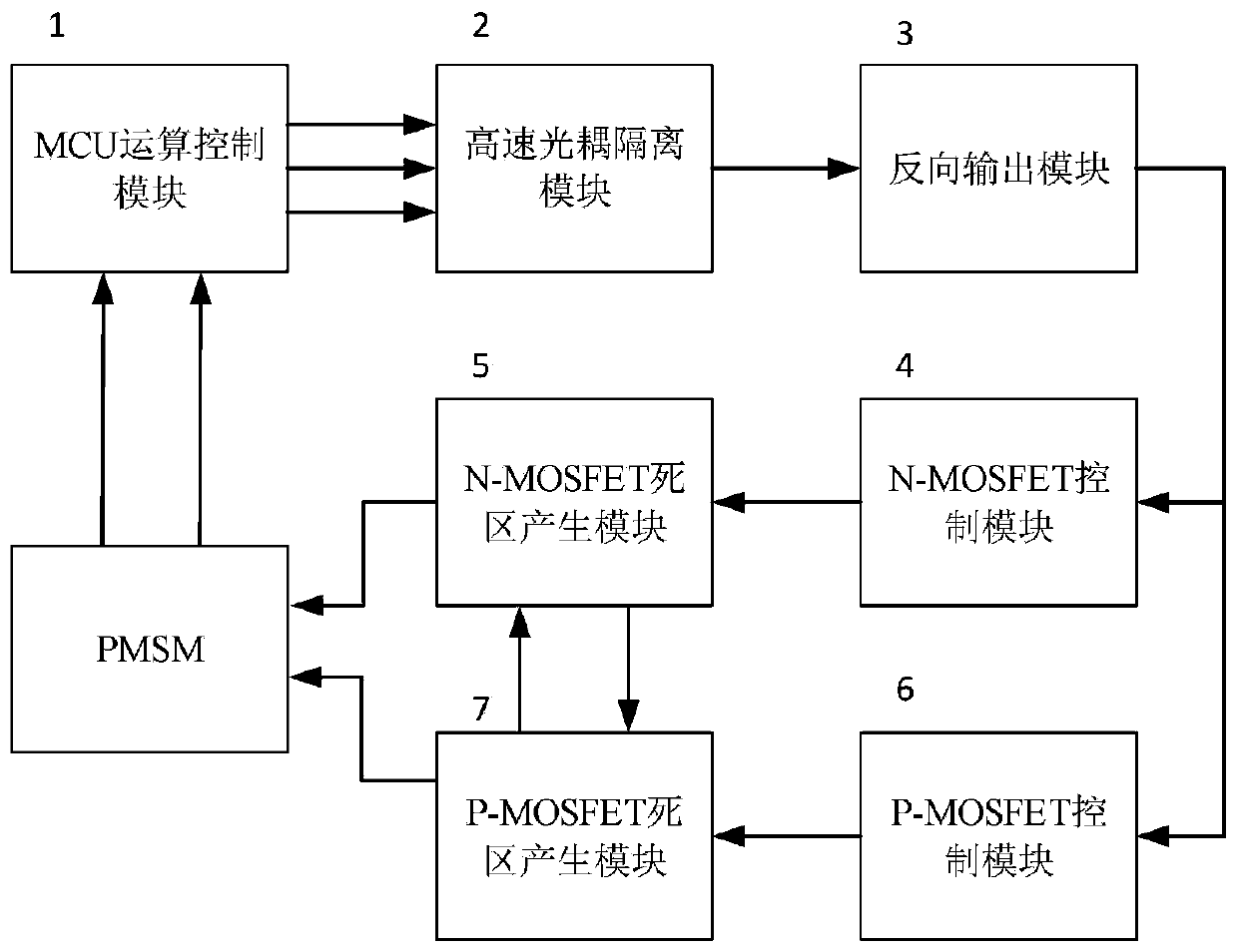

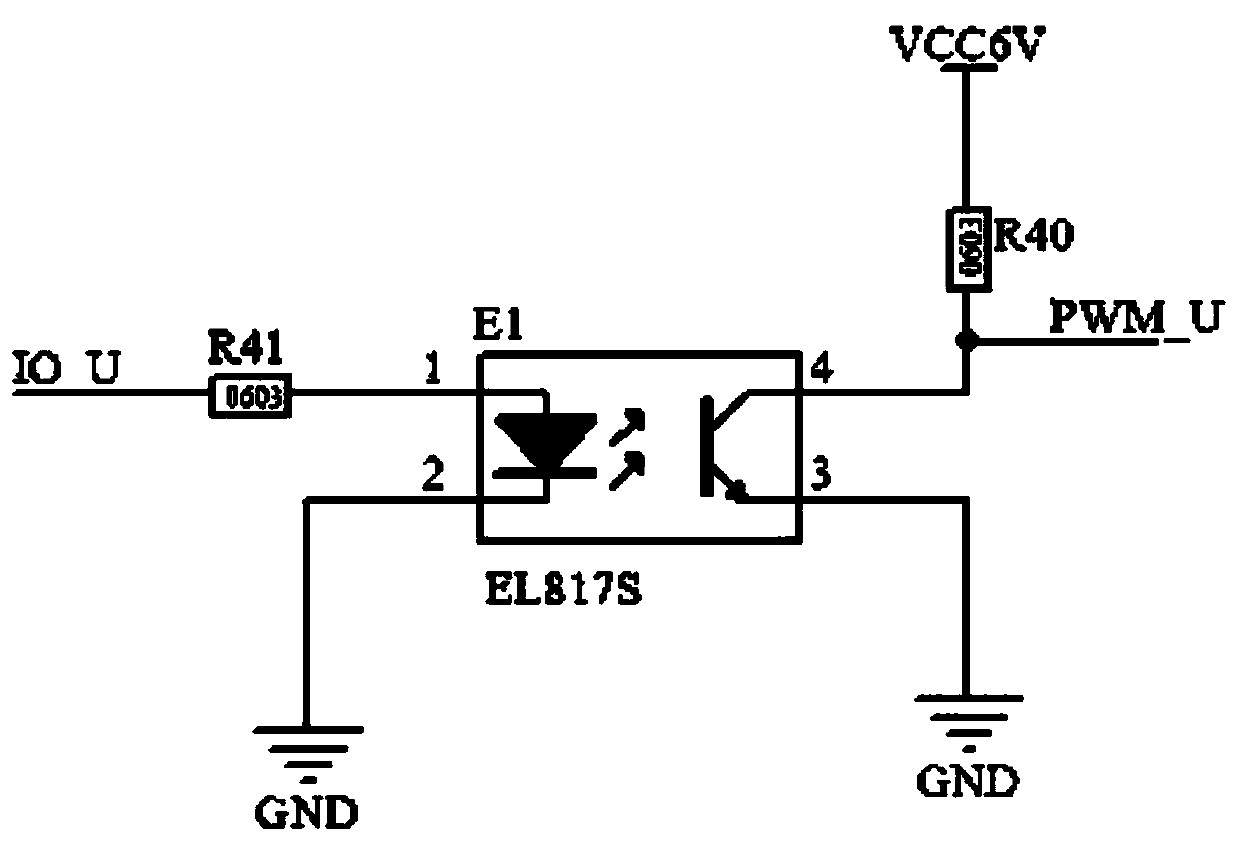

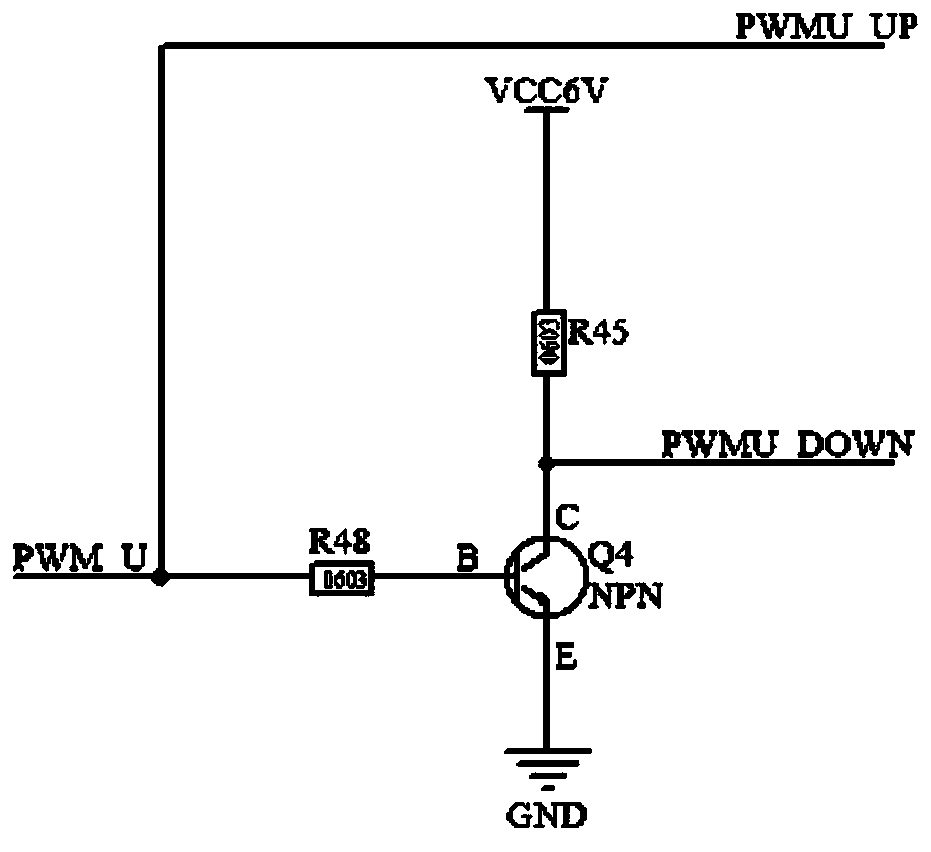

[0036] Such as figure 1 As shown, a permanent magnet synchronous motor drive circuit with hardware protection of N-NOSFET and P-MOSFET includes MCU operation control module (1), high-speed optocoupler isolation module (2), reverse output module (3), N-MOSFET control module (4), N-MOSFET dead zone generation module (5), P-MOSFET control module (6), P-MOSFET control module (7). The MCU operation control module outputs three-phase U, V, W three-way PWM waves into the high-speed optocoupler isolation module (2), taking the U phase as an example for explanation, the remaining two phases are the same as the U phase, and the optocoupler isolated PWM The signal enters the reverse output module (3), which reverses the output of the PWM signal to realize the output of two complementary and symmetrical PWM waves, one enters the lower bridge arm N-MOSFET control module (4), and the other enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com