Method for Determination of Laser Transmission Characteristic Value

A technology of transmission characteristics and determination methods, applied in laser welding equipment, structural parts, battery box/sleeve materials, etc., can solve the problems that labels do not have other functions, increase material costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

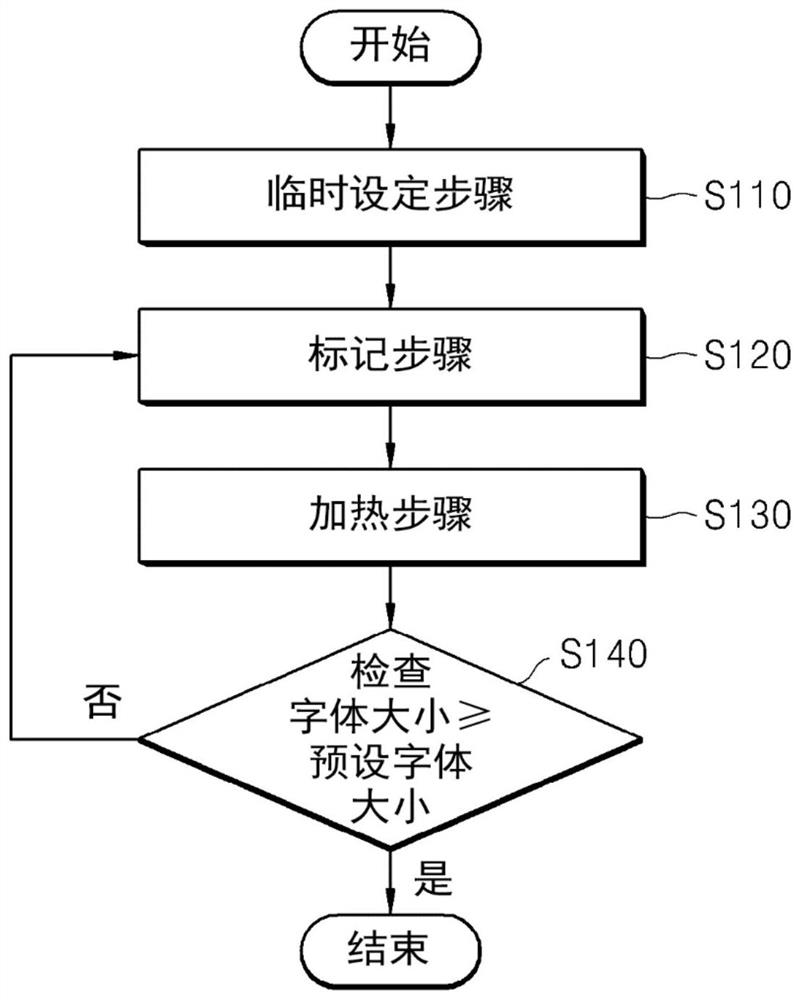

[0040] Next, a laser transmission characteristic value determination method according to an embodiment of the present invention will be described.

[0041] The laser transmission characteristic value determination method according to an embodiment of the present invention uses a laser with a set optional transmission characteristic value to mark letters in a heat-shrinkable tube, and after applying heat, checks the font size, and adjusts the transmission characteristic value so that the font size The set font size is reached. Therefore, the readability of the letters marked on the heat shrink tubing can be increased, so that the label configuration can be eliminated.

[0042] figure 2 is a flowchart of a method for determining a laser transmission characteristic value according to an embodiment of the present invention.

[0043] refer to figure 2 , in the laser transmission characteristic value determination method according to the embodiment of the present invention, the...

Embodiment 2

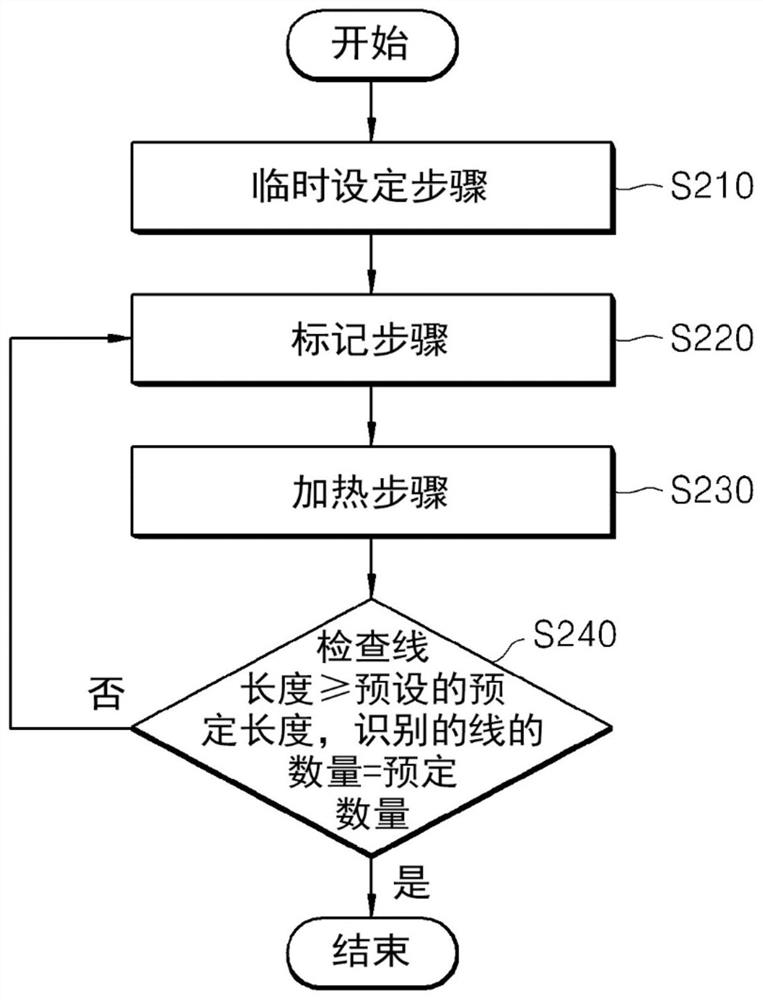

[0063] Next, a laser transmission characteristic value determination method according to another embodiment of the present invention will be described.

[0064] According to a laser transmission characteristic value determining method according to another embodiment of the present invention, a laser having an arbitrarily set transmission characteristic value is used to mark a readout symbol formed by a predetermined number of lines in a heat-shrinkable tube, and after applying heat, check The number of lines of the symbol is read out and the transmission characteristic value is adjusted to recognize the number of lines as a predetermined number to ensure accurate laser transmission characteristic values.

[0065] image 3 is a flowchart of a method for determining a laser transmission characteristic value according to another embodiment of the present invention.

[0066] refer to image 3 , in the laser transmission characteristic value determining method according to anothe...

Embodiment 3

[0091] Next, a battery cell according to an embodiment of the present invention will be described.

[0092]A battery cell according to an embodiment of the present invention may be configured to include only a heat-shrinkable tube, and the information of the corresponding battery cell is input into the heat-shrinkable tube, and there is no label on the appearance of the case housing the electrode assembly, thus reducing the labeling. The cost of production and shorten the process to achieve fast production.

[0093] Figure 4 is a structural diagram of a battery cell according to an embodiment of the present invention.

[0094] refer to Figure 4 , the battery unit 100 according to an embodiment of the present invention includes: an electrode assembly 110 including an anode, a cathode, and a separator; an electrode assembly case 120 accommodating the electrode assembly; and an electrically insulating heat-shrinkable tube 130 surrounding the electrode assembly case The outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear shrinkage | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com