Baking system suitable for improving wetting uniformity of food

A food and baking technology, which is applied in food ovens, baking, food science, etc., can solve the problems of oxidative rancidity, poor consistency, and short shelf life, and achieve reduced oxygen absorption capacity, good softness and uniformity, and improved shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

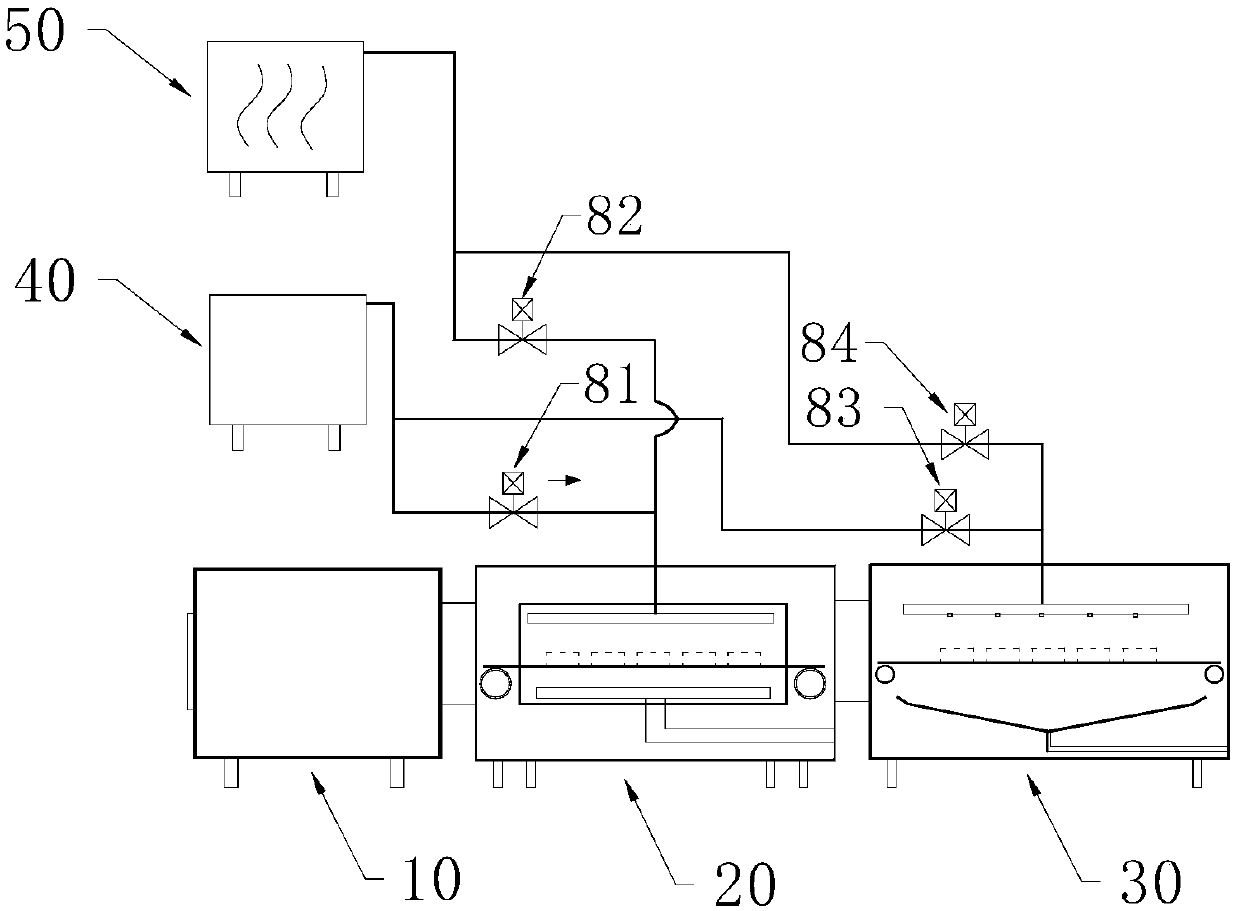

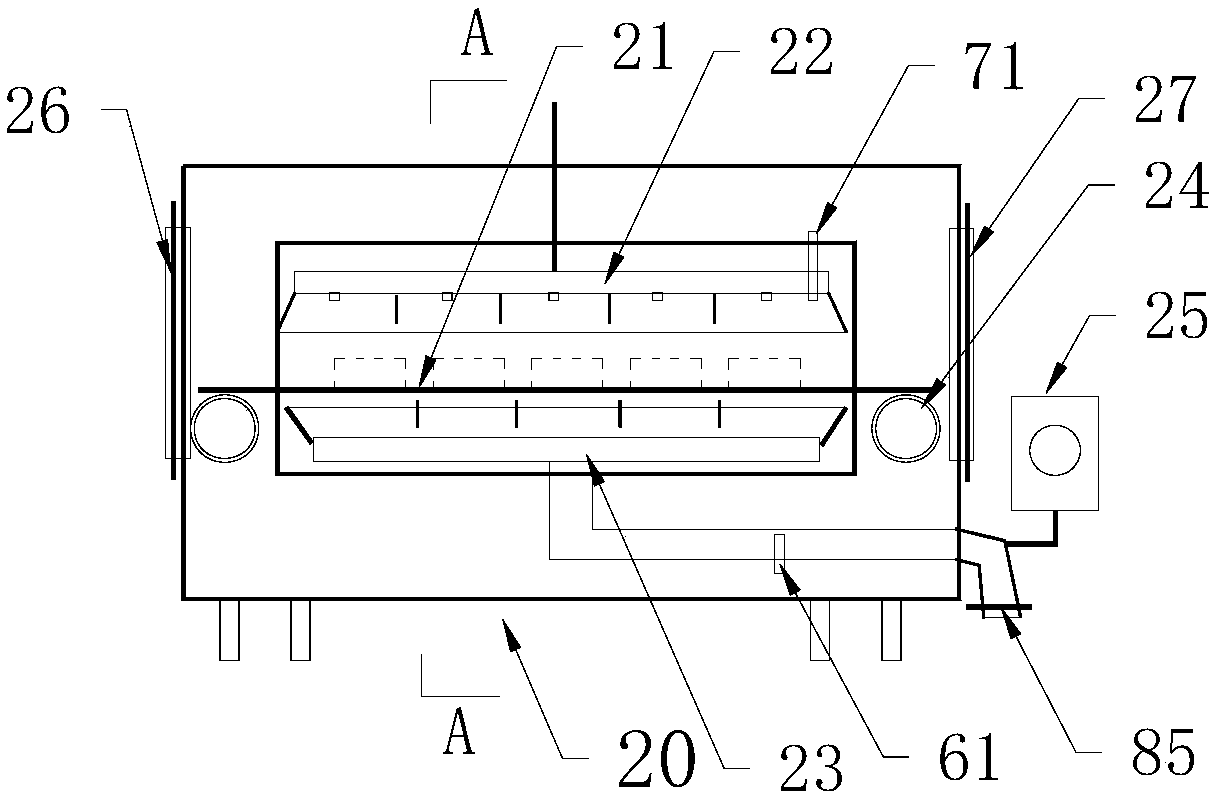

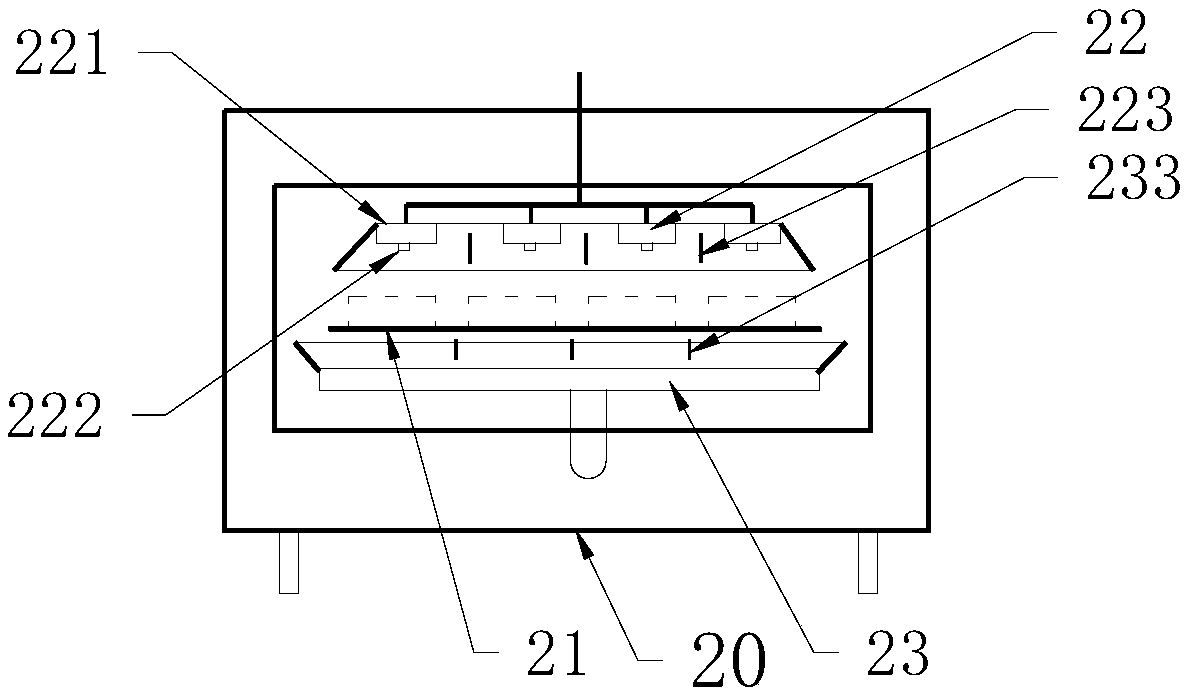

Method used

Image

Examples

Embodiment

[0058]This mooncake example shows three batches of mooncakes baked. The ingredients ratio and production process of the skin and filling of each batch of mooncakes are the same, and no preservatives are added. The above-mentioned intelligent food baking system is used for baking. Bake and cool. The first batch of mooncakes were baked and cooled in the air environment, sealed and vacuum-packed in the air environment, and the wetness and softness of the mooncakes were not improved by the input of water vapor. Ten mooncake samples were randomly selected from the baked mooncakes as For the test, 5 samples were reserved for the storage period test, and the other 5 samples were tested for oxidative deterioration and taste; the second batch of mooncakes was baked and cooled in a nitrogen protective gas environment, and water vapor was input during the baking period to improve the quality of the mooncakes. 10 mooncake samples were randomly selected from the baked mooncakes for testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com