Dish washing machine

A dishwasher and washing arm technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, automatic detection under the control of tableware washing machine/rinsing machine, etc., can solve the problem of dishwasher Large cleaning dead angle, difficult to clean thoroughly, etc., to achieve the effect of convenient daily maintenance, not easy to interfere with winding, and reduce the exposure of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

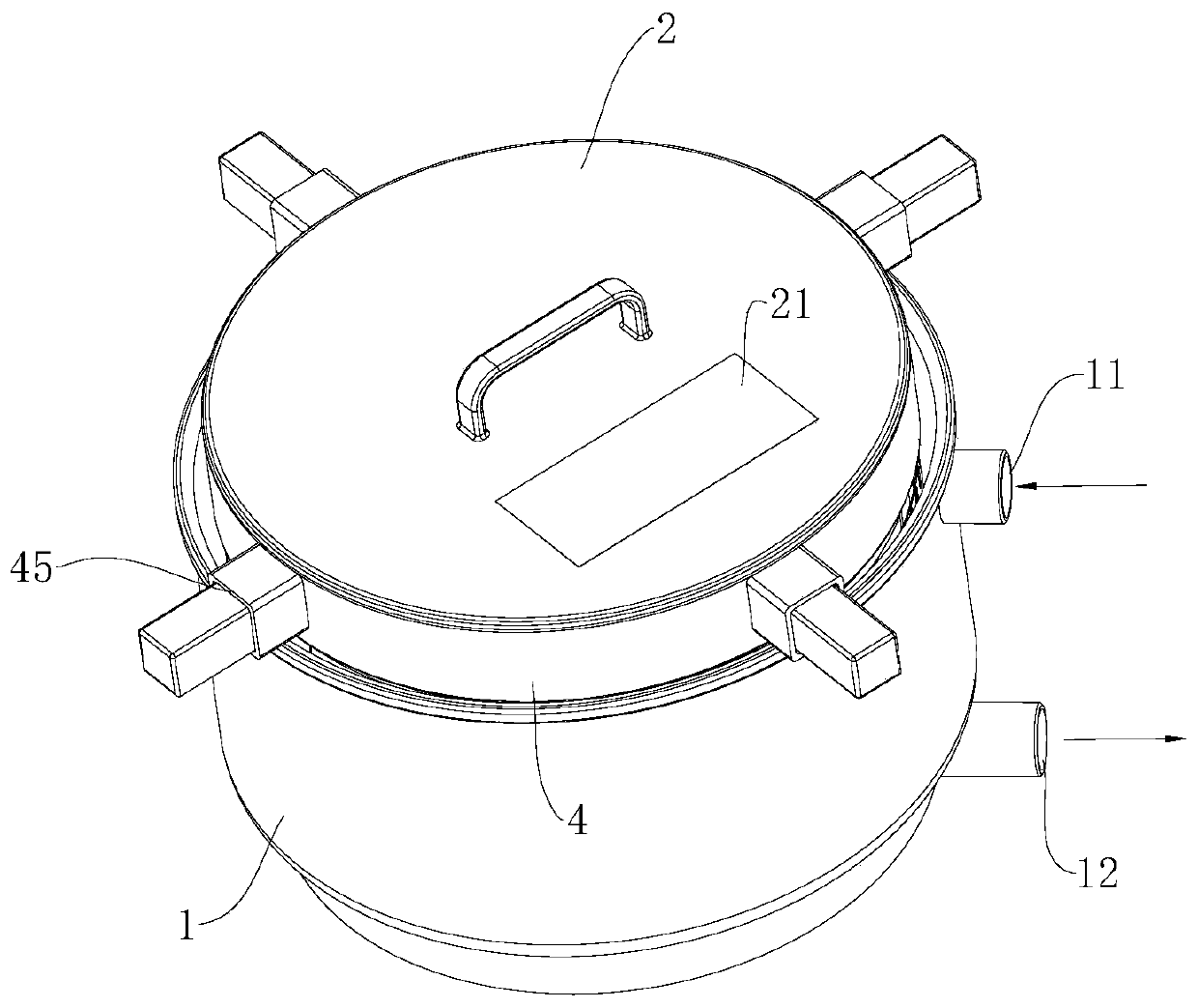

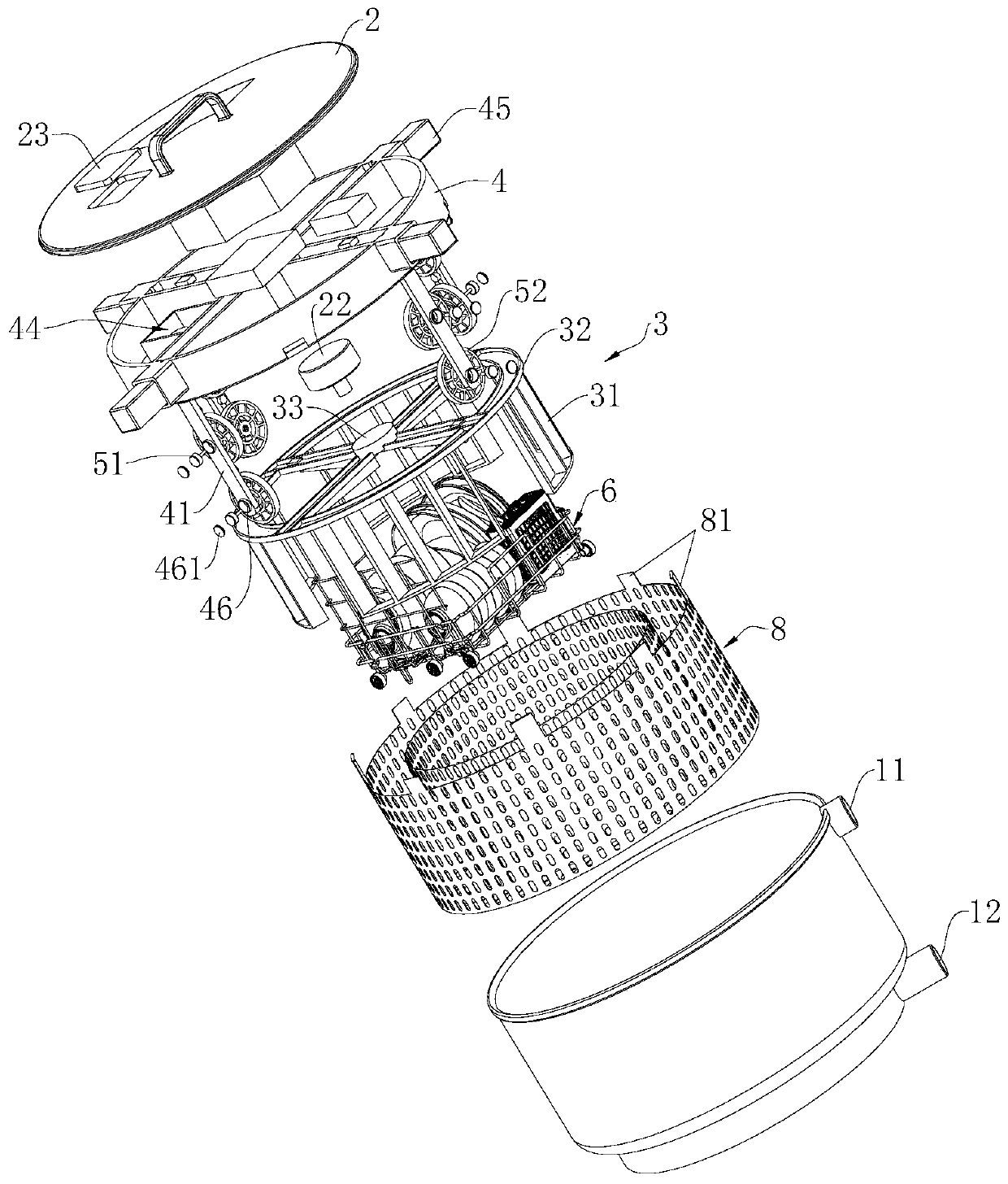

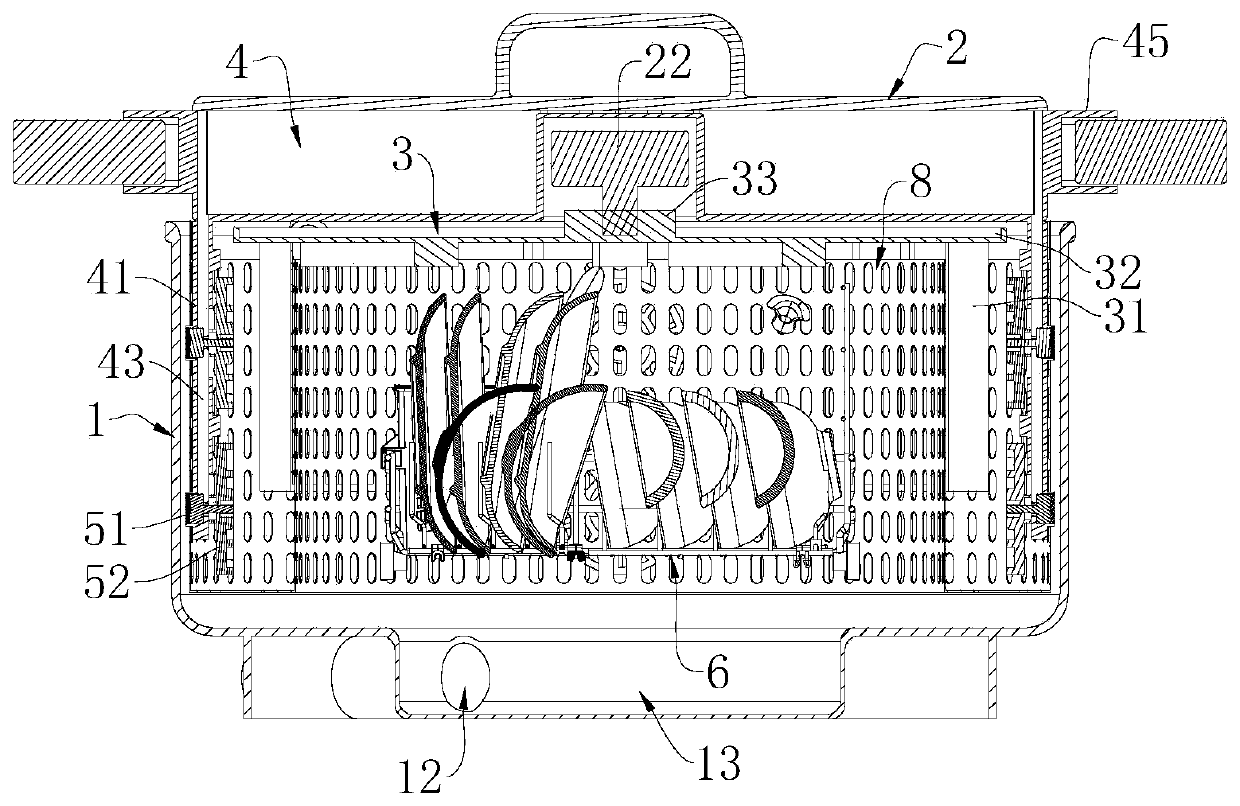

[0131] This embodiment provides a dishwasher, such as figure 1 figure 2 As shown, it includes: a cavity 1, which is provided with a cleaning space for accommodating cleaning objects; a cover 2, which is detachably connected with the cavity 1, and is used to close the cavity 1; a washing mechanism, which is arranged on the cover 2. In the dishwasher of this program, when the cover body 2 is opened after washing the dishes, the cleaned tableware is taken out. Since the washing mechanism is located on the cover body 2, when the cover body 2 is opened, the washing mechanism is lifted out together, so that only the washed tableware or fruits and vegetables remain in the cavity body 1 . After taking out the cleaning object, there is no object in the cleaning space of the cavity 1, and the user can easily wipe and clean the cavity 1. Compared with the prior art, the cleaning dead angle is basically eliminated, and the material basis for breeding bacteria is more easily removed, so...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap