Processing and transporting equipment for prefabricated box girder reinforcement cage

A steel skeleton and transportation equipment technology, applied in the field of construction engineering, can solve the problems of long time occupied by steel bar binding, increase construction cost, slow construction progress, etc., achieve high construction efficiency, shorten steel bar forming time, and speed up construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

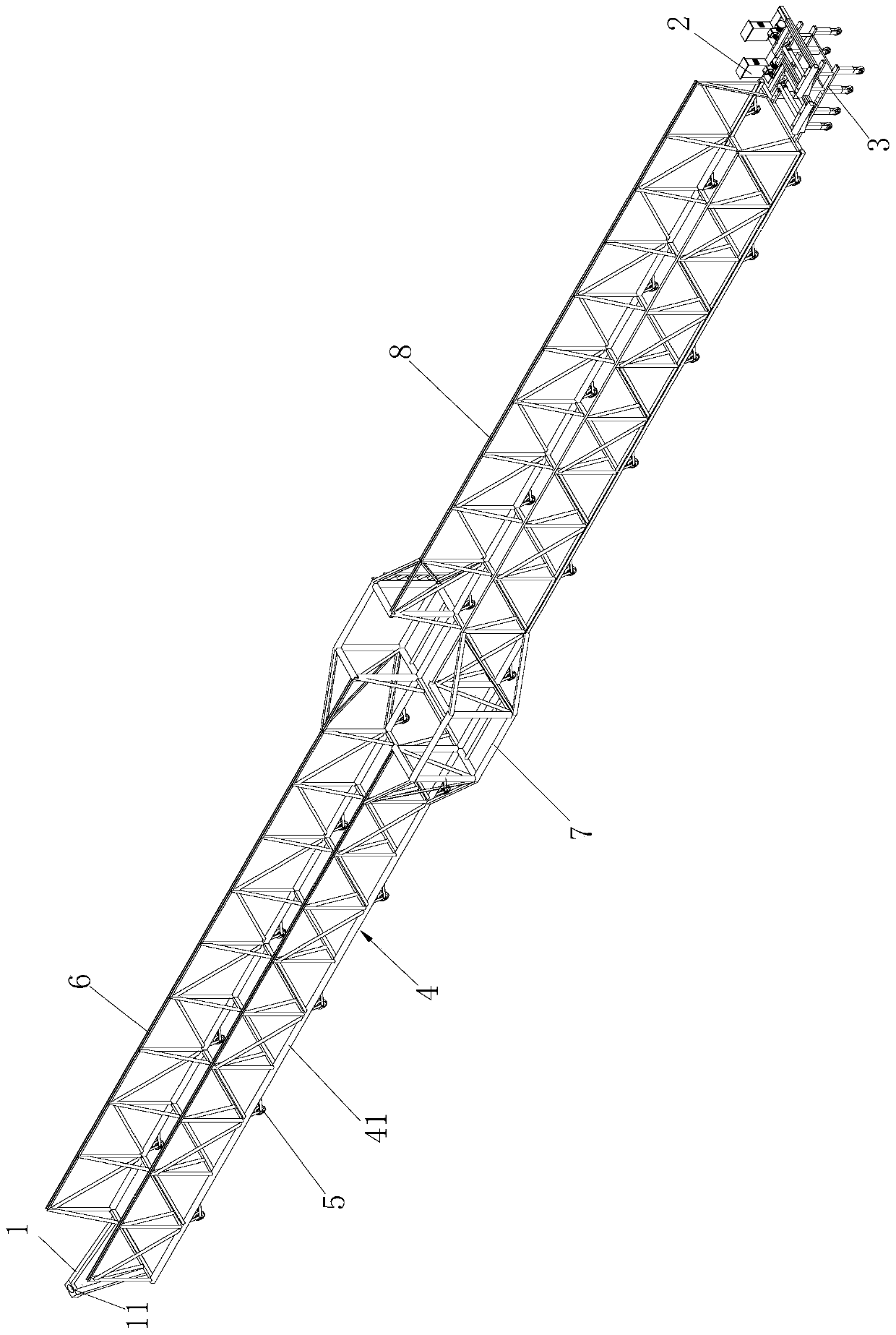

[0046] combine Figure 1 to Figure 9 , a processing and transportation equipment for prefabricated box girder steel skeleton, including a tractor, which can use a forklift as the tractor for transportation power. The rear end of the tractor is connected with a transport vehicle through the traction frame 1, and the rear end of the transport vehicle is connected with a main rib threading device 2 and a pipe threading device 3; A plurality of frame roller assemblies 5.

[0047] The vehicle frame mechanism 4 includes an underframe 41 , and the upper end of the underframe 41 is connected with a front limiting mechanism 6 , a middle mounting mechanism 7 and a rear limiting mechanism 8 . The front limit mechanism 6 includes two first vertical brackets 61, the two first vertical brackets 61 are connected to the front upper end of the chassis 41 parallel to each other, and the inside of the first vertical bracket 61 is connected with a plurality of first diagonal struts 62. .

[00...

Embodiment 2

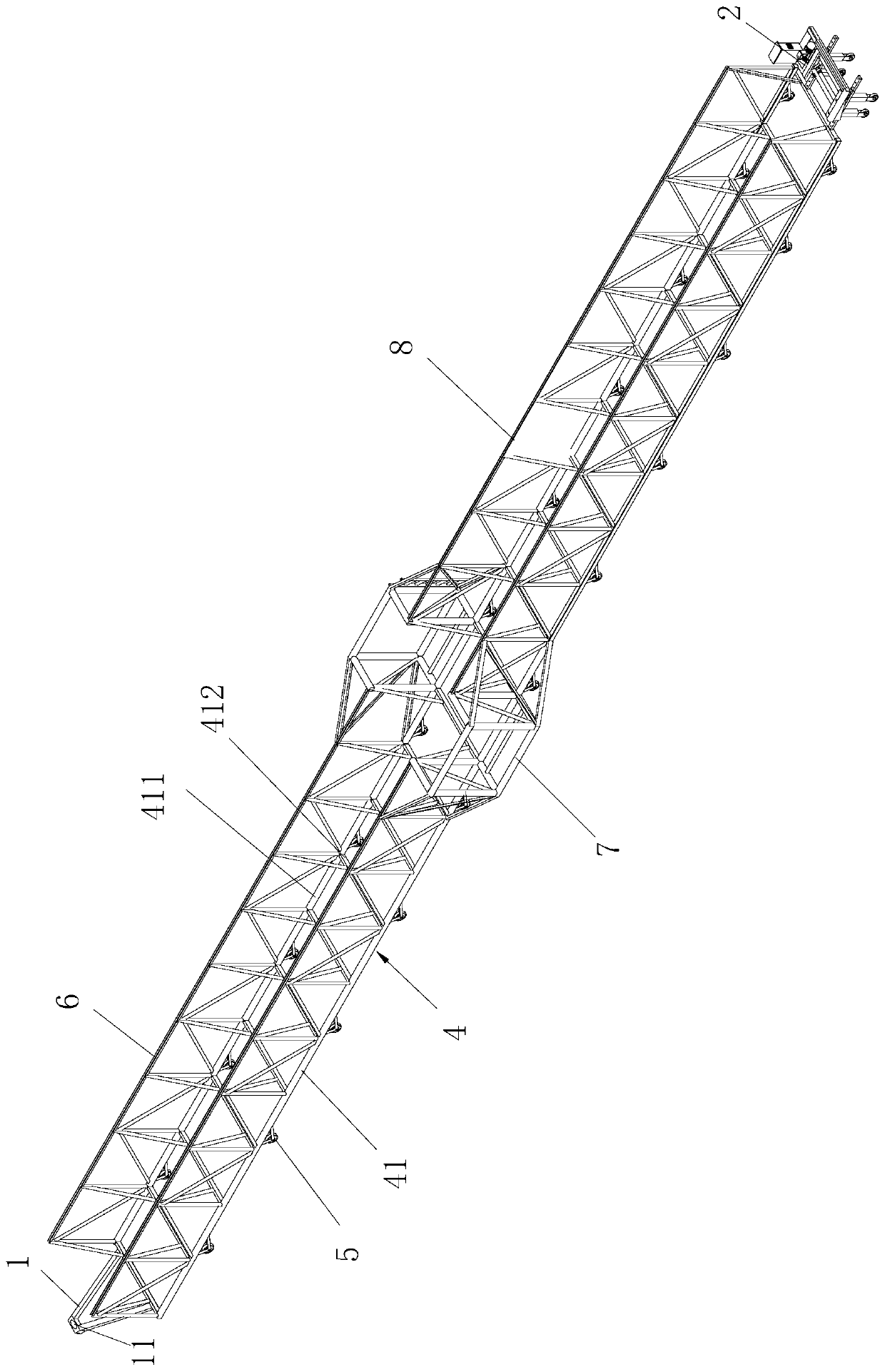

[0071] A processing and transporting equipment for prefabricated box girder reinforced skeleton, comprising a tractor, characterized in that the rear end of the tractor is connected with a transport vehicle through a traction frame 1, and the rear end of the transport vehicle is connected with a main tendon threading device 2; The transport vehicle includes a frame mechanism 4 and a plurality of frame roller assemblies 5 connected to the lower end of the frame mechanism 4;

[0072] The vehicle frame mechanism 4 includes an underframe 41 , and the upper end of the underframe 41 is connected with a front limiting mechanism 6 , a middle mounting mechanism 7 and a rear limiting mechanism 8 . The front limit mechanism 6 includes two first vertical brackets 61, the two first vertical brackets 61 are connected to the front upper end of the chassis 41 parallel to each other, and the inside of the first vertical bracket 61 is connected with a plurality of first diagonal struts 62. .

...

Embodiment 3

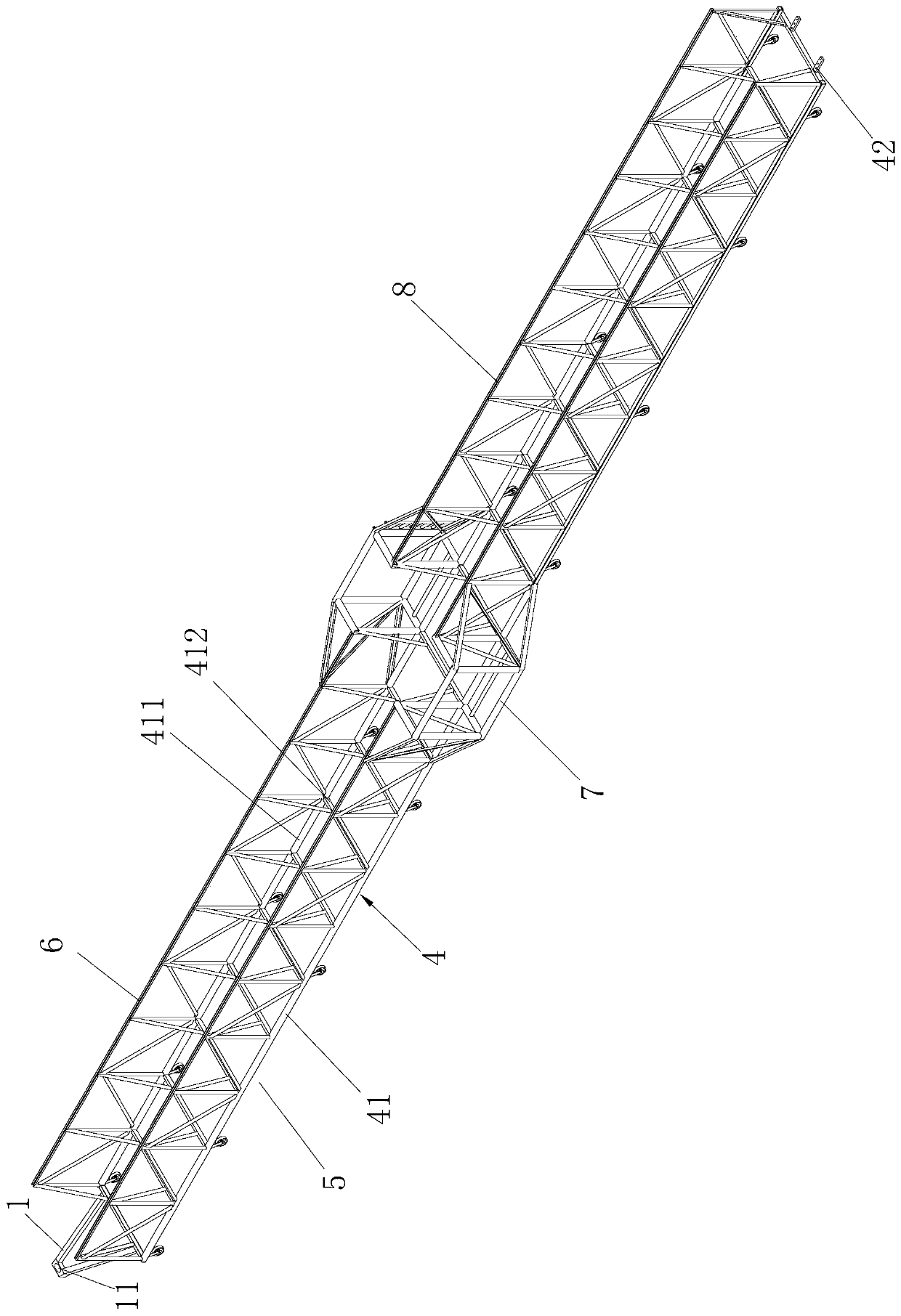

[0078] A kind of processing and transportation equipment for prefabricated box girder steel skeleton, comprising a tractor, the rear end of the tractor is connected with a transport vehicle, a main tendon threading device 2 and a pipe threading device 3 through a traction frame 1; the transport vehicle includes a vehicle The frame mechanism 4 and a plurality of frame roller assemblies 5 connected to the lower end of the frame mechanism 4 .

[0079] The rear limit mechanism includes two second vertical brackets 81, the two second vertical brackets 81 are connected to the rear upper end of the chassis 41 in parallel, and the inside of the second vertical brackets 81 is connected with a plurality of second diagonal struts. 82. The main tendon threading device 2 includes a first mobile frame 21 and a steel bar threading mechanism 22 connected to the upper end of the first mobile frame 21, the rear end of the chassis 41 is connected with a first chassis connecting rod 42, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com