Drive anti-skid control method applied to automobile electric drive axle

A technology of electric drive axle and control method, which is applied in the direction of control drive, control device, electric vehicle, etc., and can solve problems such as poor road adaptability, poor control robustness, and single control algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention is described in detail below in conjunction with accompanying drawing:

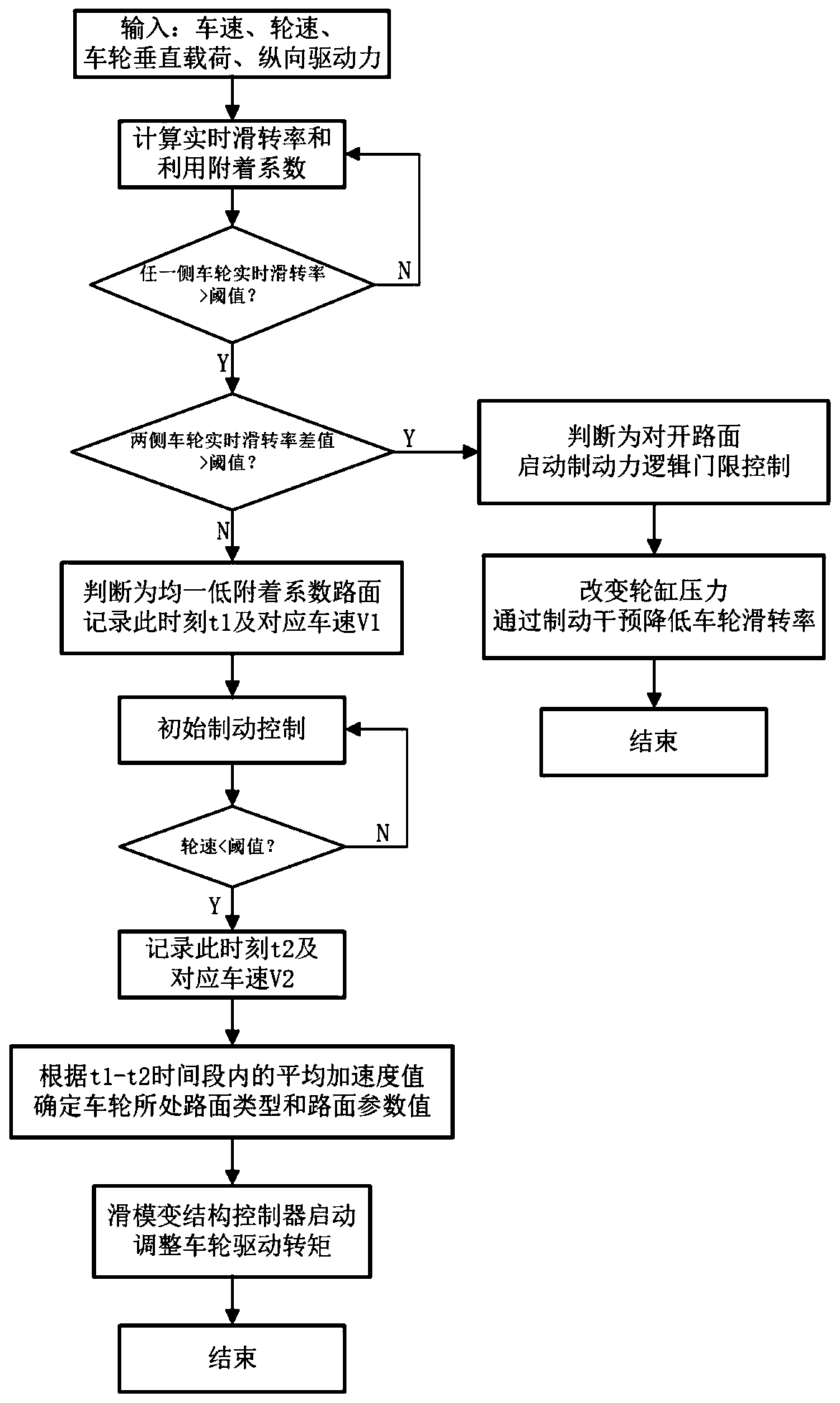

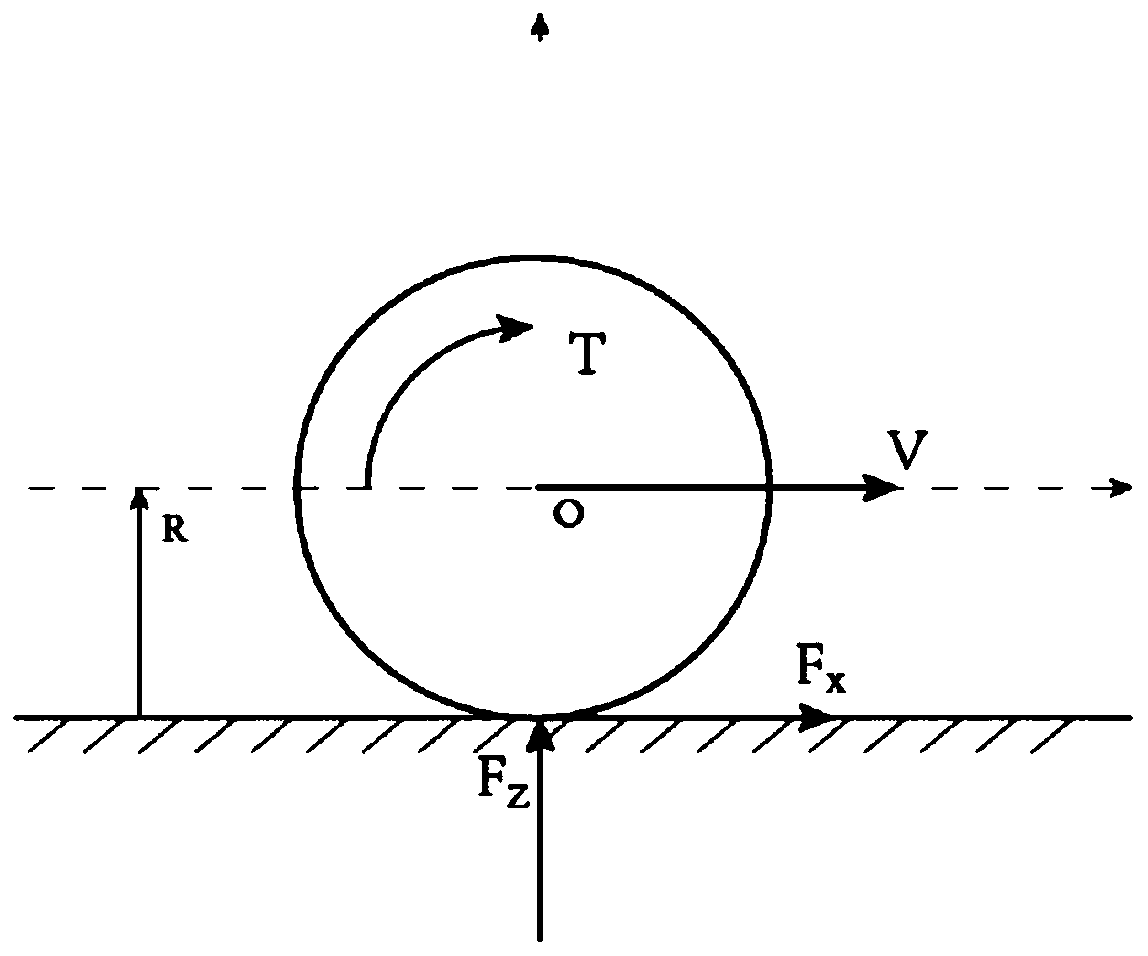

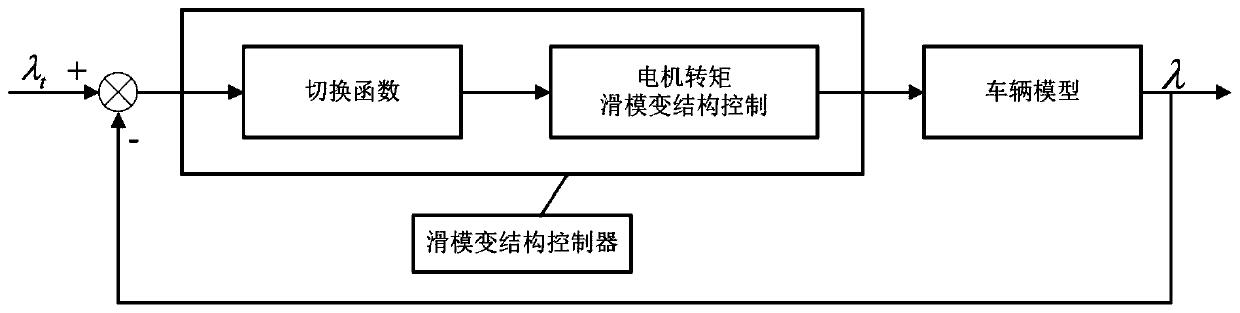

[0088] The invention discloses a drive anti-slip control method applied to an electric drive axle of an automobile. According to the real-time slip rate of the wheels and the difference between the real-time slip rates of the wheels on both sides, it is judged that the vehicle is on a split road surface or a uniform low adhesion coefficient road surface, and the braking force is adopted. The logic threshold control performs braking intervention on the slipping wheels on the open road, and uses the initial braking method to further judge the road type of the slipping wheels on the uniform low adhesion coefficient road, and uses the sliding mode variable structure control to adjust the driving of the slipping wheels Torque, so as to achieve the control effect of maintaining the wheel slip rate at the optimal value according to the type of road surface.

[0089] see figure 1 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com