Bracket for smoke exhaust pipe of main generator of semisubmersible drilling platform and setting method thereof

A technology for drilling platforms and main generators, applied in the field of brackets, can solve problems such as inability to effectively support the exhaust pipe and complicated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

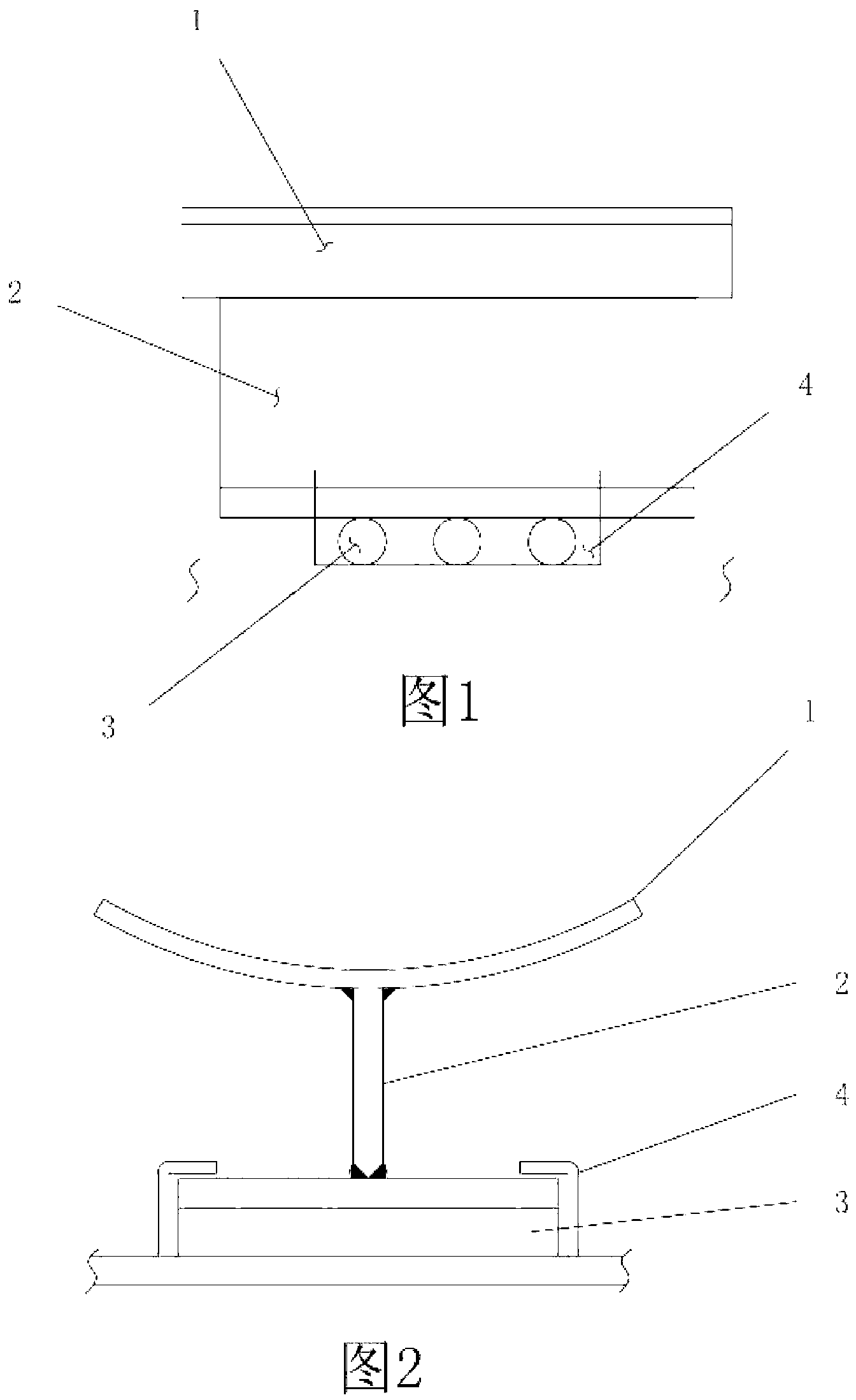

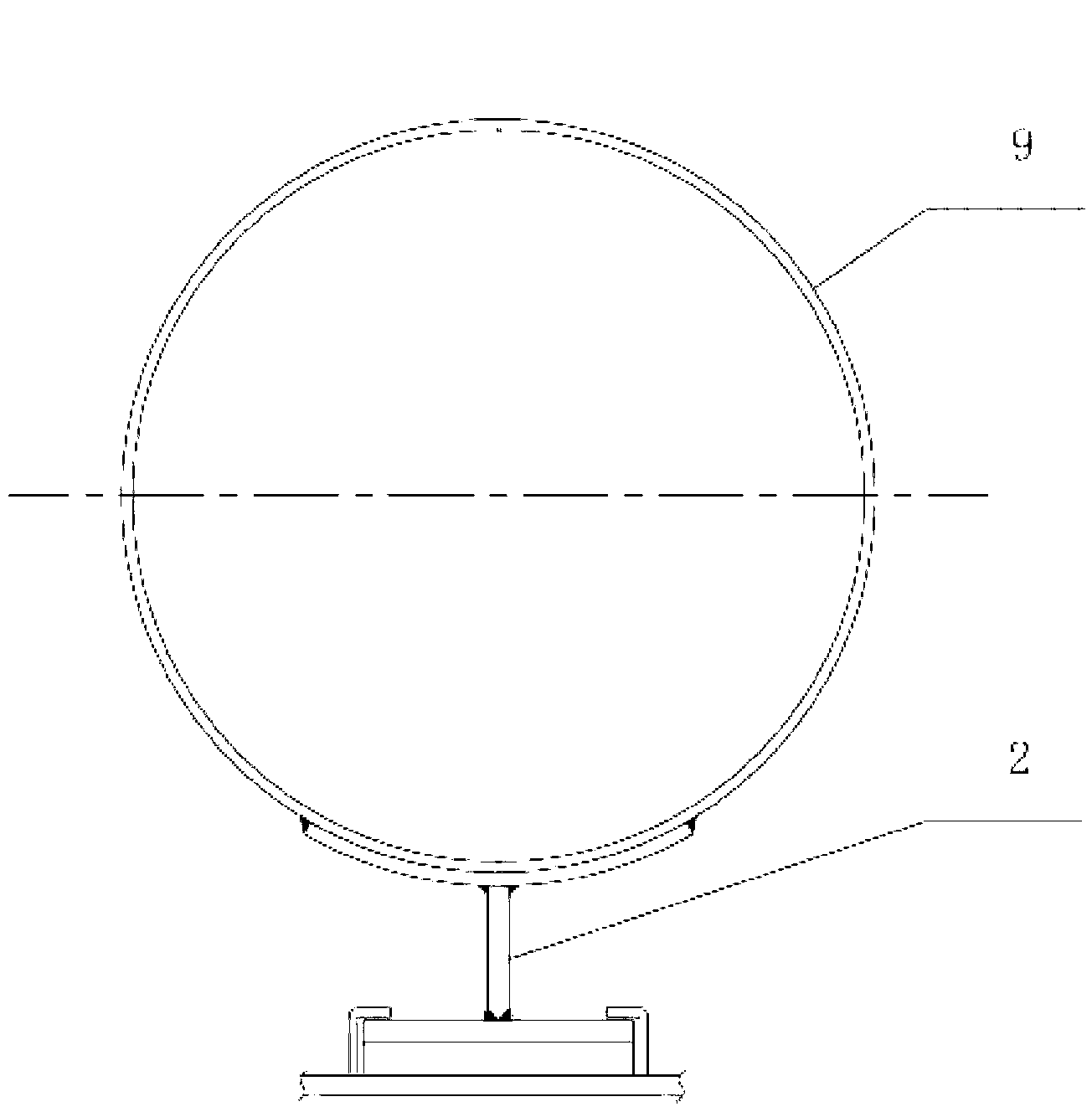

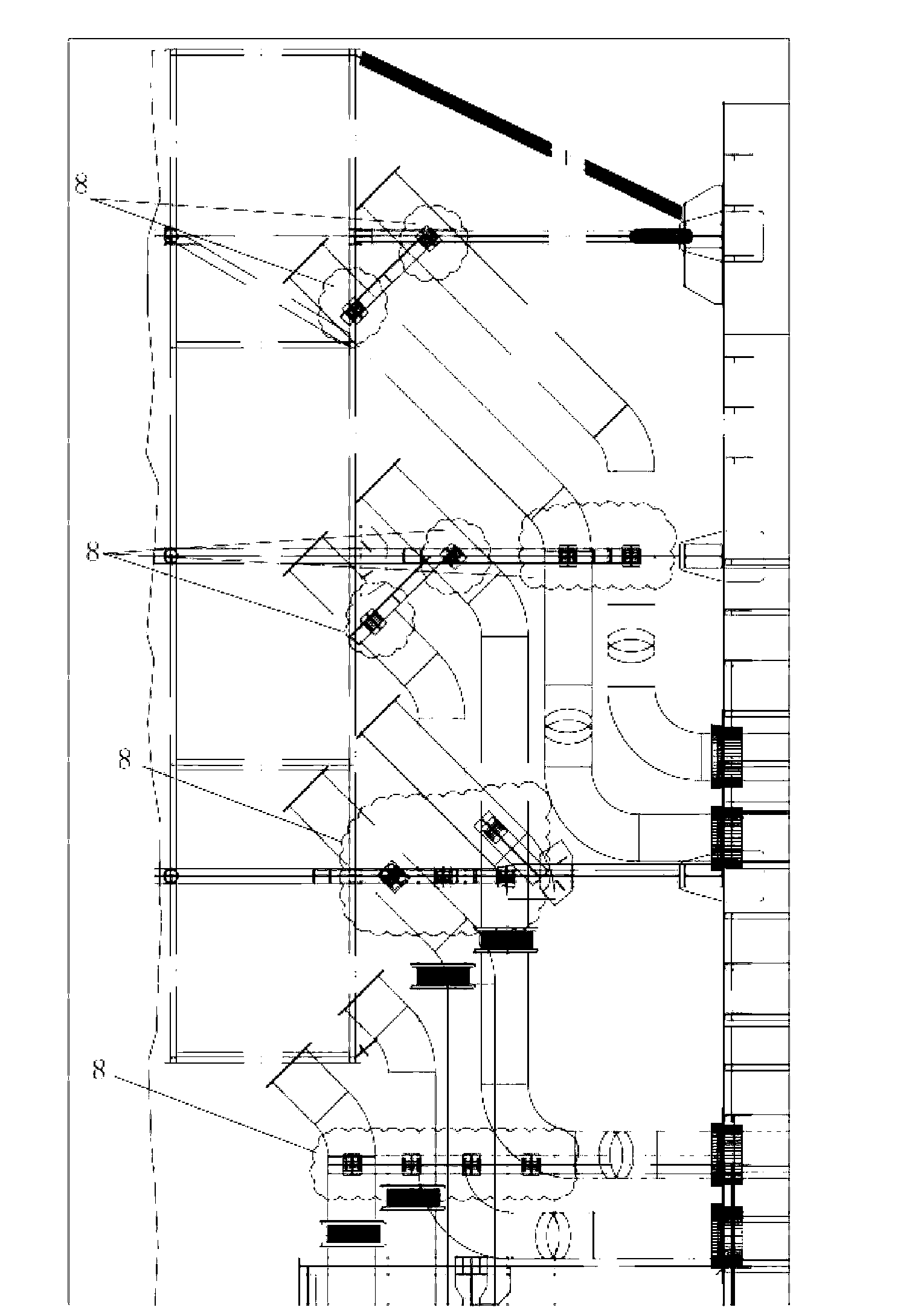

[0019] figure 1 and figure 2 It is the production and installation form of the T-shaped vertical plate type smoke exhaust pipe sliding support of the main generator smoke exhaust pipe of the semi-submersible drilling platform of the present invention. image 3 It is an application example of the T-shaped vertical plate type smoke exhaust pipe sliding support of the main generator smoke exhaust pipe of the semi-submersible drilling platform of the present invention. exist Figure 1-3 Among them, the bracket of the present invention includes a T-shaped component 2 welded by two flat plates; the vertical plate in the T-shaped component 2 is located at the top, and the flat plate is located at the bottom. Wherein, the top of the vertical plate of the T-shaped assembly is welded to the middle of the arc-shaped web 1; the inner diameter of the web 1 is equal to the outer diameter of the exhaust pipe to be supported. The lower end surface of the plate is placed on the rollers 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com