An ovd deposition device with high deposition pass rate

A deposition device and pass rate technology, which is applied in the field of OVD deposition devices with high deposition pass rate, can solve the problems of low deposition pass rate of optical fiber preform loose body and loose fiber preform body detached from the chuck, so as to improve the deposition pass rate , Reduce the concentricity error of the core package, and prevent the effect of losing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

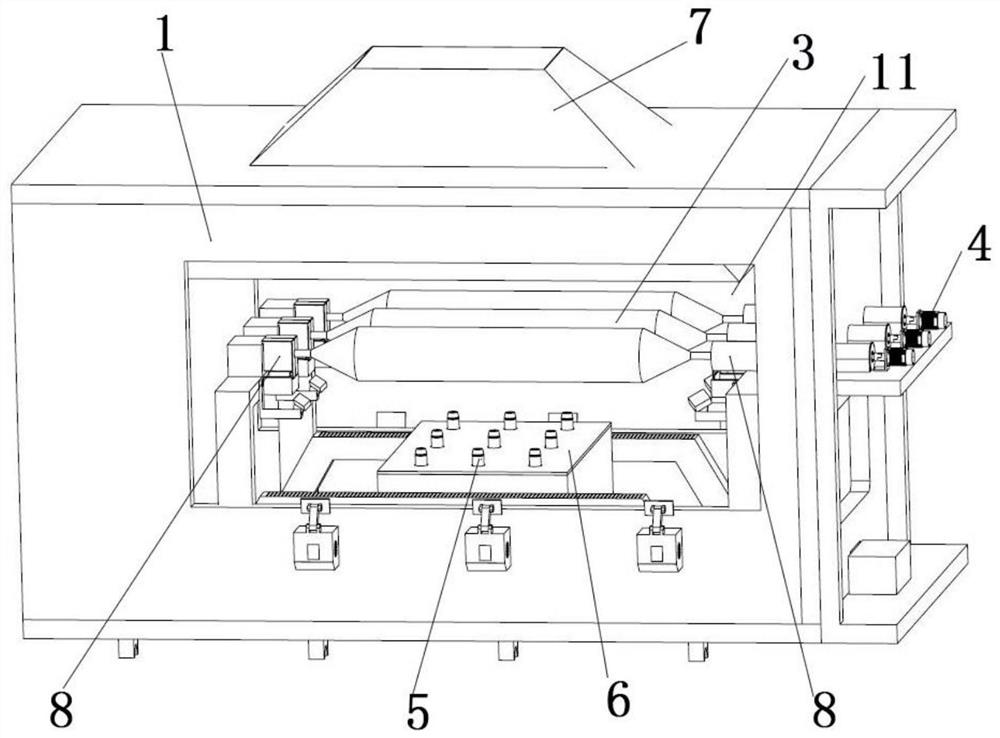

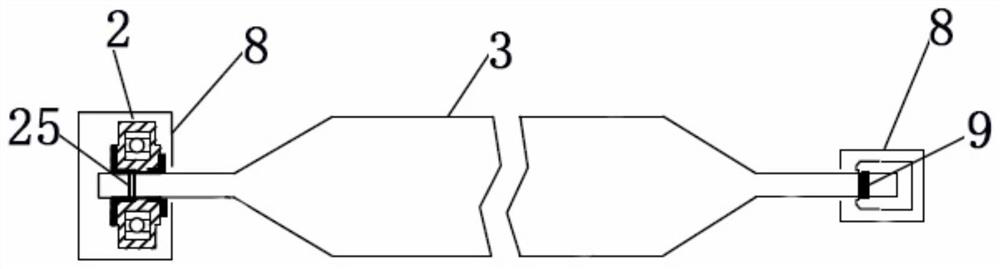

[0037] This embodiment provides an OVD deposition device with a high deposition pass rate, such as figure 1 and figure 2 shown, including:

[0038] The deposition box 1 has a deposition cavity 11 for accommodating the preform soot or core rod 3;

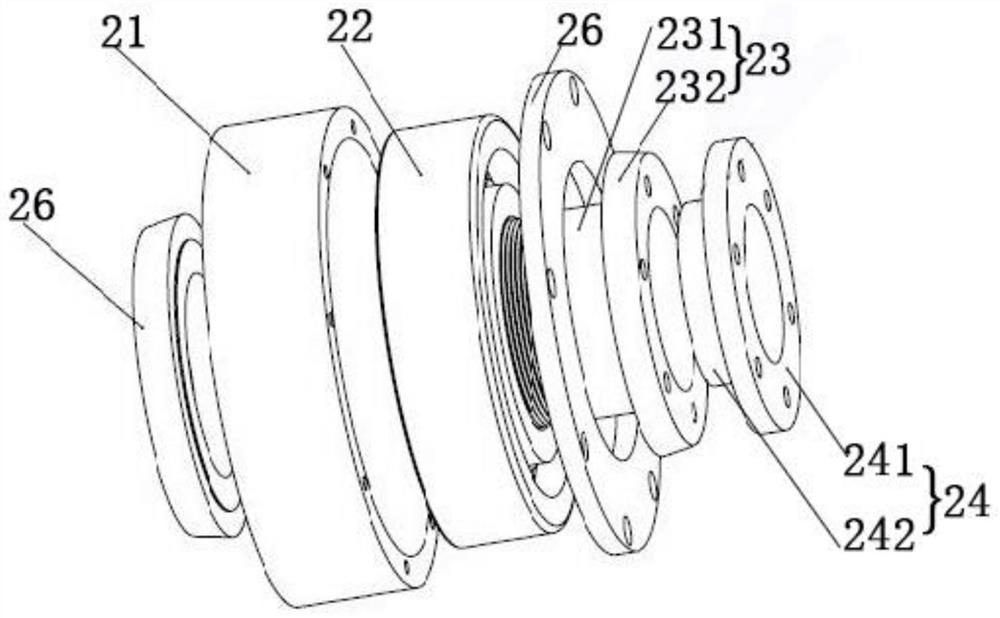

[0039] The support structure 2 is arranged on one side of the deposition cavity 11; as image 3As shown, the bearing support structure 2 includes a fixed seat 21 (specifically, a bearing seat), a sliding ring 22 (specifically, a bearing), a fixed tube 23, and a pressing member 24. The fixed seat 21 is arranged in the deposition box 1 , the sliding ring 22 is accommodated in the fixing seat 21, the fixing tube 23 extends into the hole of the sliding ring 22 from one side of the sliding ring 22, and the cavity of the fixing tube 23 is provided with a loose body or a core for fixing the preform rod The elastic part 25 of the rod 3 (such as the O-shaped rubber sealing ring for the loose body of the preform rod or the mandrel 3 to pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com