Metal wire repair method for display substrate, lens and laser used for the method

A technology for displaying substrates and repair methods, applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve problems such as poor repair effect of metal wire fractures, achieve the effect of improving the success rate of repair and ensuring the continuity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0033] An embodiment of the present invention provides a metal wire repair method for a display substrate, wherein the method includes:

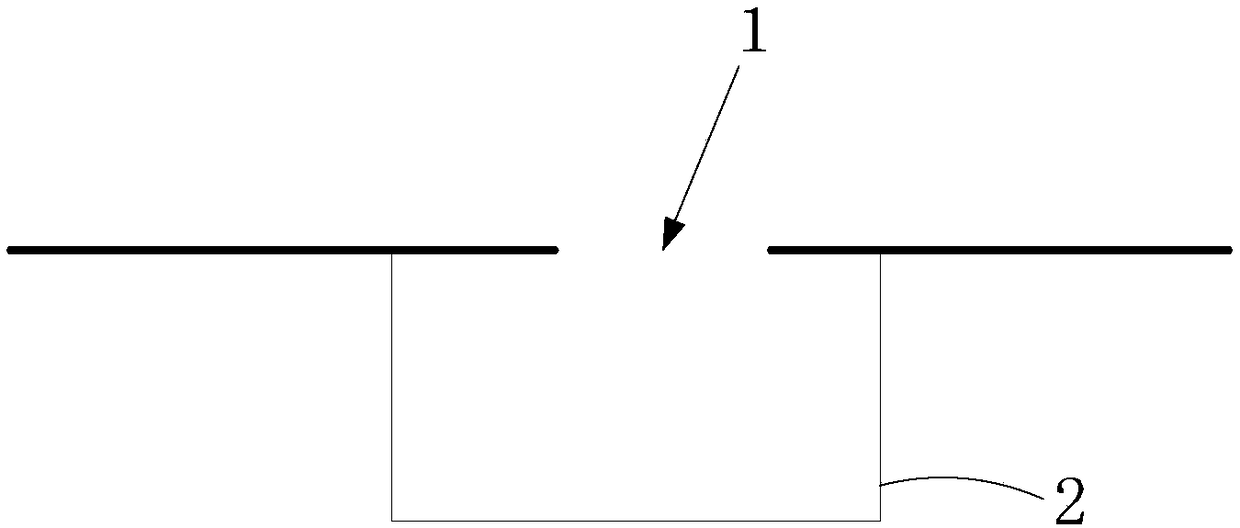

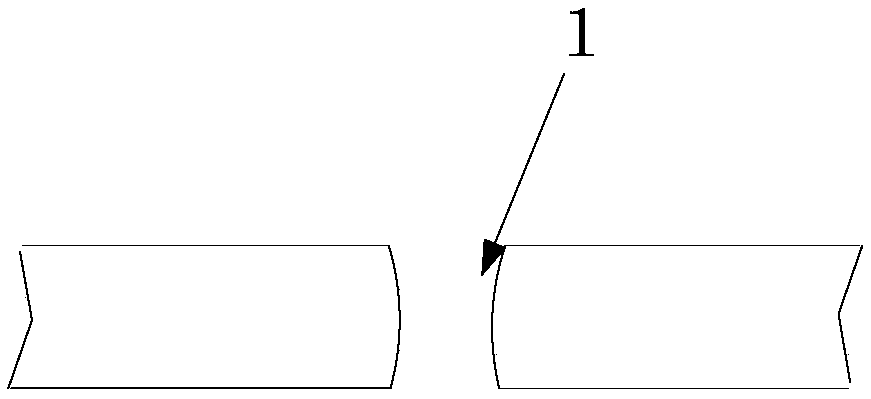

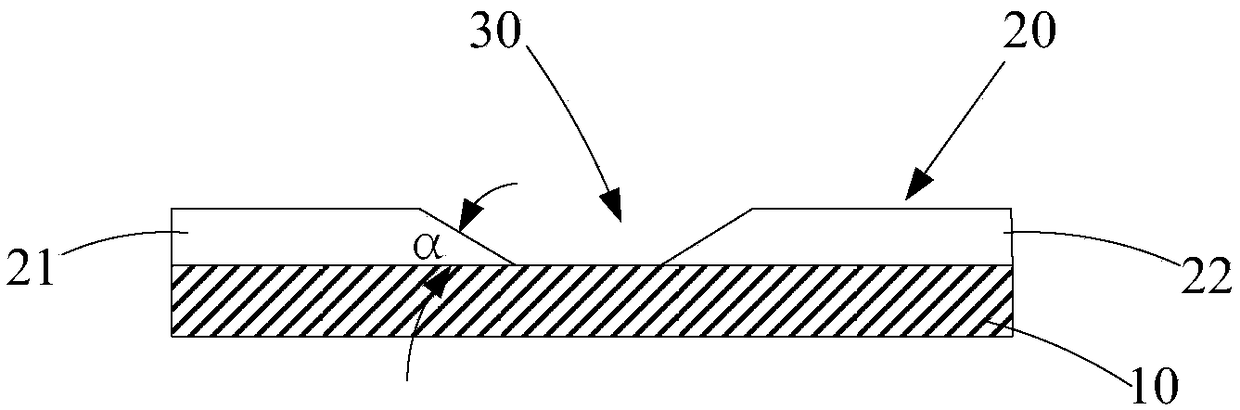

[0034] The breakpoint of the metal wire is laser processed by the laser output laser beam to form a fracture structure. The cross sections of the metal wires on both sides of the fracture structure are respectively formed as smooth slopes, and the slopes are inclined relative to the extending direction of the metal wires on the side. The angle is less than 90 degrees;

[0035] A conductive material is deposited on the fracture structure to form a connection line connecting the metal lines on both sides of the fracture structure.

[0036] like image 3 Shown is a schematic diagram of laser processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com