A zinc oxide negative electrode material for a zinc-air battery and a preparation method thereof

A zinc-air battery and negative electrode material technology, applied in battery electrodes, negative electrodes, active material electrodes, etc., can solve the problems of low high-current charging capacity of zinc negative electrodes, insufficient structural strength of the coating layer, insufficient cycle life, etc. Effects of improved current charging capability, reduced concentration polarization, and extended cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

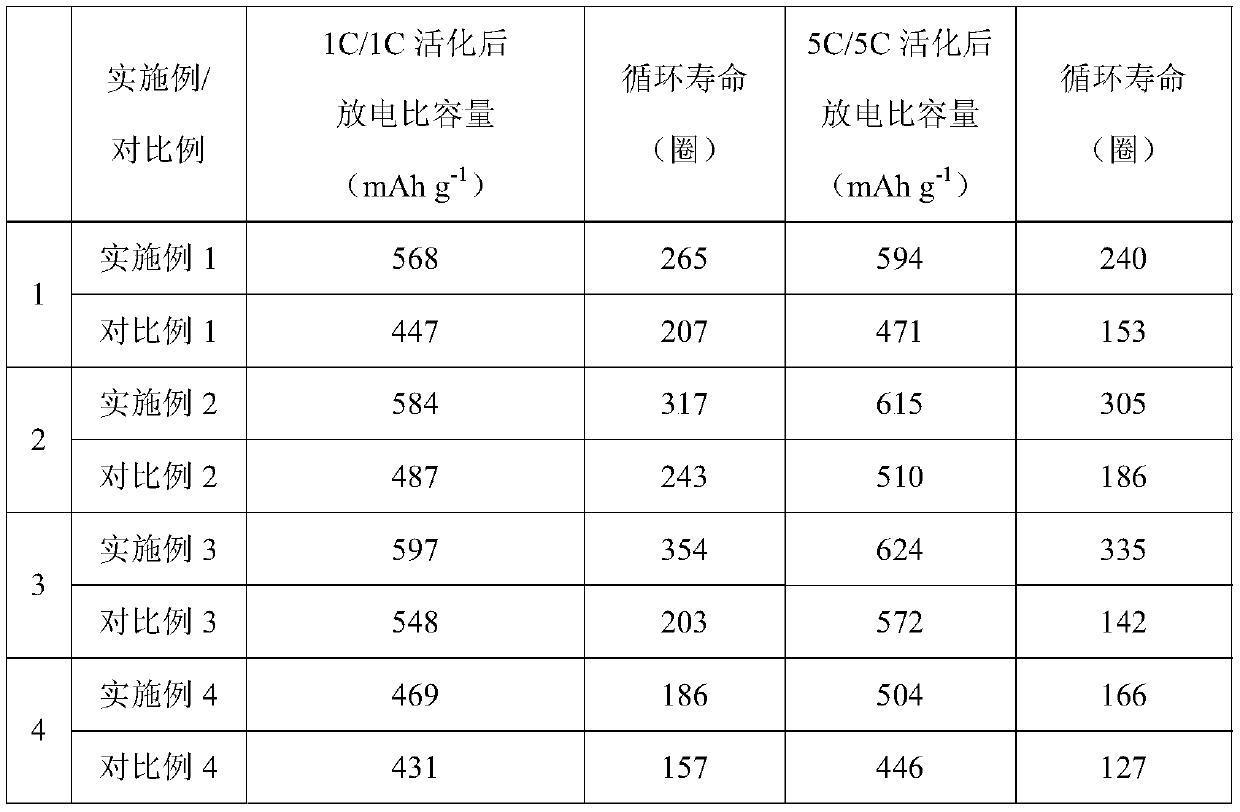

Embodiment 1

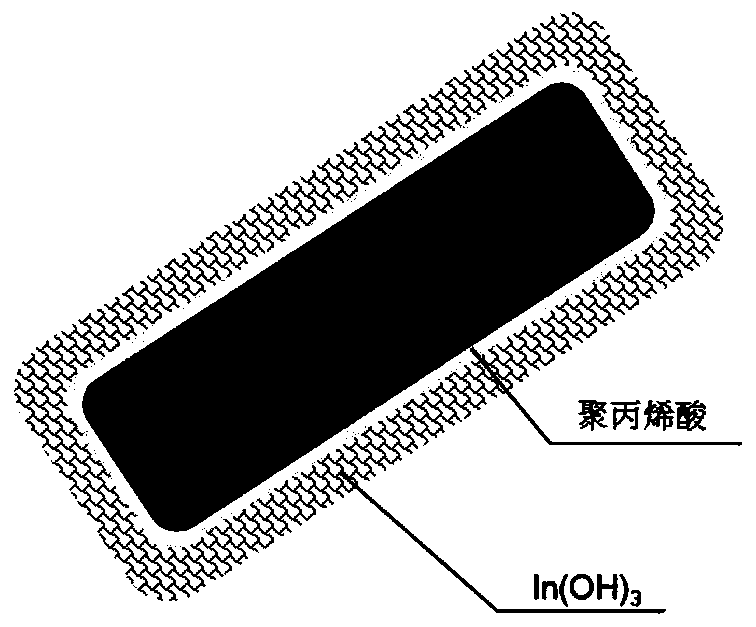

[0036] Zinc oxide negative electrode material: the thickness of the polyacrylic acid layer of the inner coating layer is 5nm, and the thickness of the outer coating layer of indium hydroxide is 3nm.

[0037] Preparation of zinc oxide negative electrode material: Add 0.5 g of zinc oxide (0.2-0.7 microns in particle size) into 50 ml of deionized water, ultrasonically disperse for 30 min, add 0.05 g of aminopropyltriethoxysilane, and stir at room temperature for 5 hours. After the product is separated by centrifugation, it is alternately washed with ethanol and water for three times, and dried in vacuum to obtain amino functionalized zinc oxide. Then, the amino-functionalized zinc oxide was added to 250ml concentration of 0.26mmol / L acrylic acid monomer solution, ultrasonically dispersed for 10min and stirred for 2h, and the ammonium persulfate initiator whose content was 2wt% of the polymer monomer was added and started at 80°C Polymerization. After reacting for 4 hours, the pr...

Embodiment 2

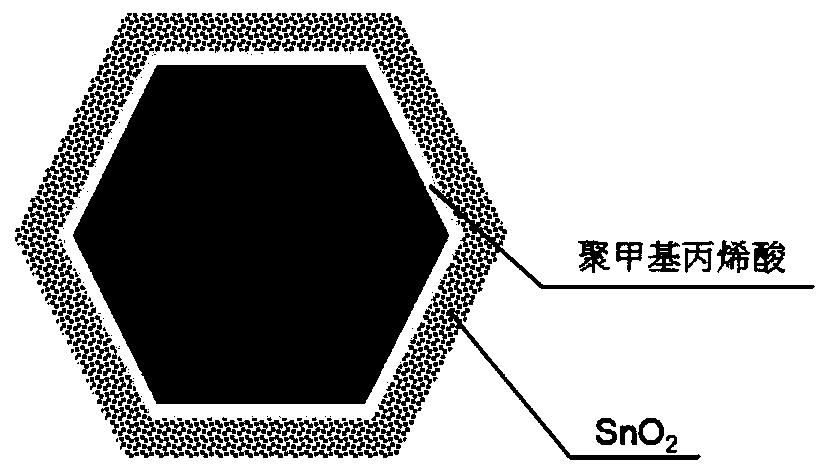

[0041] Zinc oxide negative electrode material: the thickness of the polymethacrylic acid layer of the inner coating layer is 5nm, and the thickness of the tin dioxide layer of the outer coating layer is 5nm.

[0042] Preparation of zinc oxide negative electrode material: Add 1 g of zinc oxide into 100 ml of deionized water, ultrasonically disperse for 30 min, add 0.3 g of aminopropyltriethoxysilane, and stir at room temperature for 4 hours. After the product is separated by centrifugation, it is alternately washed with ethanol and water for three times, and dried in vacuum to obtain amino functionalized zinc oxide. Then, 0.5 g of amino-functionalized zinc oxide was added to 250 ml of a concentration of 0.26 mmol / L methacrylic acid monomer solution, ultrasonically dispersed for 10 min and stirred for 3 h, and an ammonium persulfate initiator with a content of 1.5 wt % of the polymer monomer was added at 65 。 C starts the polymerization reaction. After reacting for 7 hours, th...

Embodiment 3

[0045] Zinc oxide negative electrode material: the thickness of the inner coating layer of acrylic methacrylic acid copolymer layer is 6nm, and the thickness of the outer coating layer of indium hydroxide is 10nm.

[0046] Preparation of zinc oxide negative electrode material: Add 0.5 g of zinc oxide into 50 ml of deionized water, ultrasonically disperse for 30 min, add 0.25 g of aminopropyltriethoxysilane, and stir at room temperature for 3 hours. After the product is separated by centrifugation, it is alternately washed with ethanol and water for three times, and dried in vacuum to obtain amino functionalized zinc oxide. Then, add amino-functionalized zinc oxide to 250ml of polymer monomer solution with a concentration of 0.27mmol / L (acrylic acid monomer:methacrylic acid monomer molar ratio=1:1), ultrasonically disperse for 10min and stir for 2h, add content The ammonium persulfate initiator, which is 3 wt% of polymer monomers, starts the polymerization reaction at 85°C. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com