An electrospinning device for preparing composite fibers

An electrospinning and composite fiber technology, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve problems such as poor performance and mechanical properties, and achieve the elimination of electrostatic adsorption force, convenient operation, and volume reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

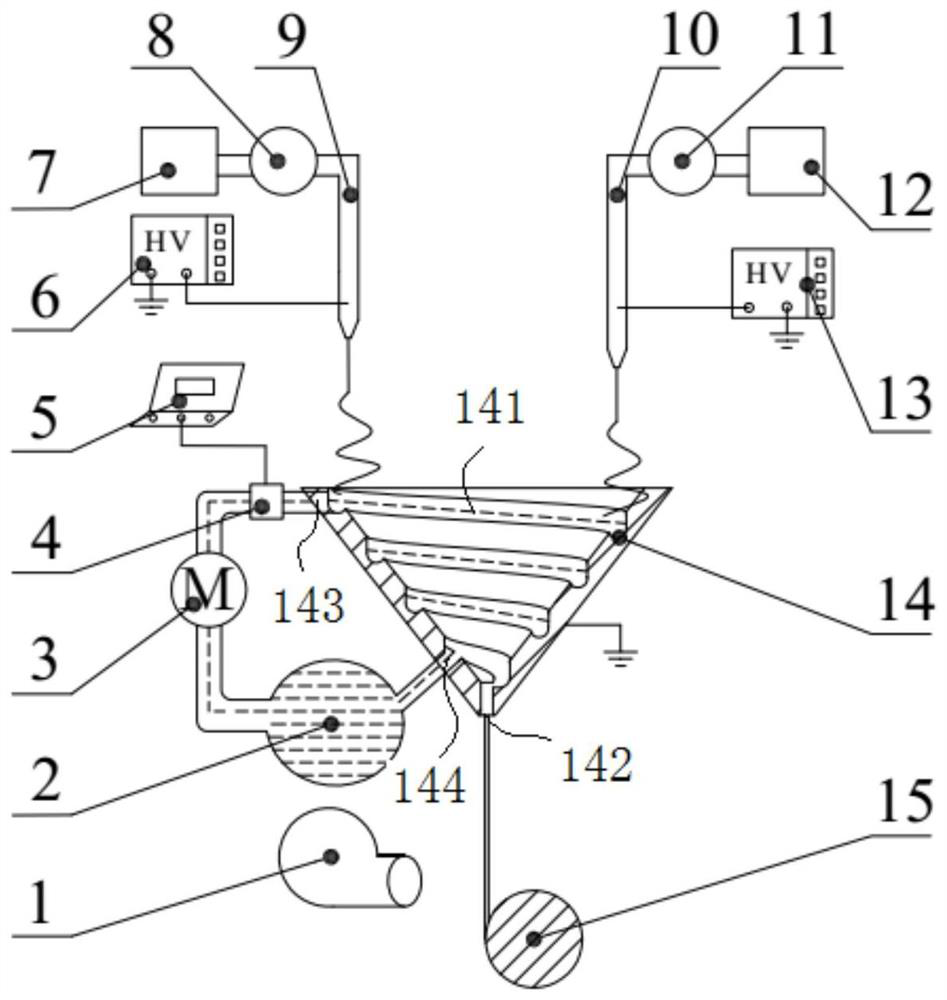

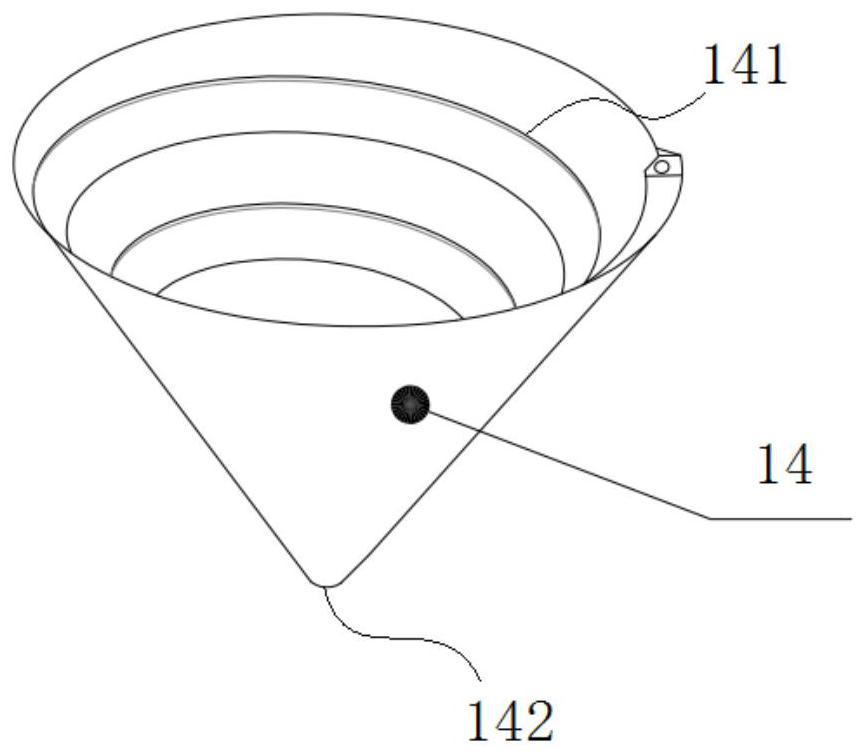

[0034] refer to figure 1 and figure 2 , an electrospinning device for preparing composite fibers, comprising a first spinning assembly, a second spinning assembly, a first high-voltage electrostatic generator 6, a second high-voltage electrostatic generator 13, a conical water bath 14, and a water bath circulation device And collection roller 15;

[0035] The first spinning assembly includes the first liquid storage tank 7, the first solution pump 8 and the first nozzle 9 connected in sequence, the first nozzle 9 is connected with the positive pole or the negative pole of the first high-voltage electrostatic generator 6, and the first high-voltage electrostatic generator 6 The other pole of device 6 is grounded.

[0036] The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com