Combined type easy-demolding high-rise building form

A high-rise building, easy demoulding technology, applied in the direction of formwork/formwork components, construction, formwork/formwork/work frame connectors, etc., can solve the problems of low fixing convenience, poor combination convenience, and complicated fixing methods. , to achieve the effect of improving connection convenience and fixing strength, improving locking strength and efficiency, and reducing complicated operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

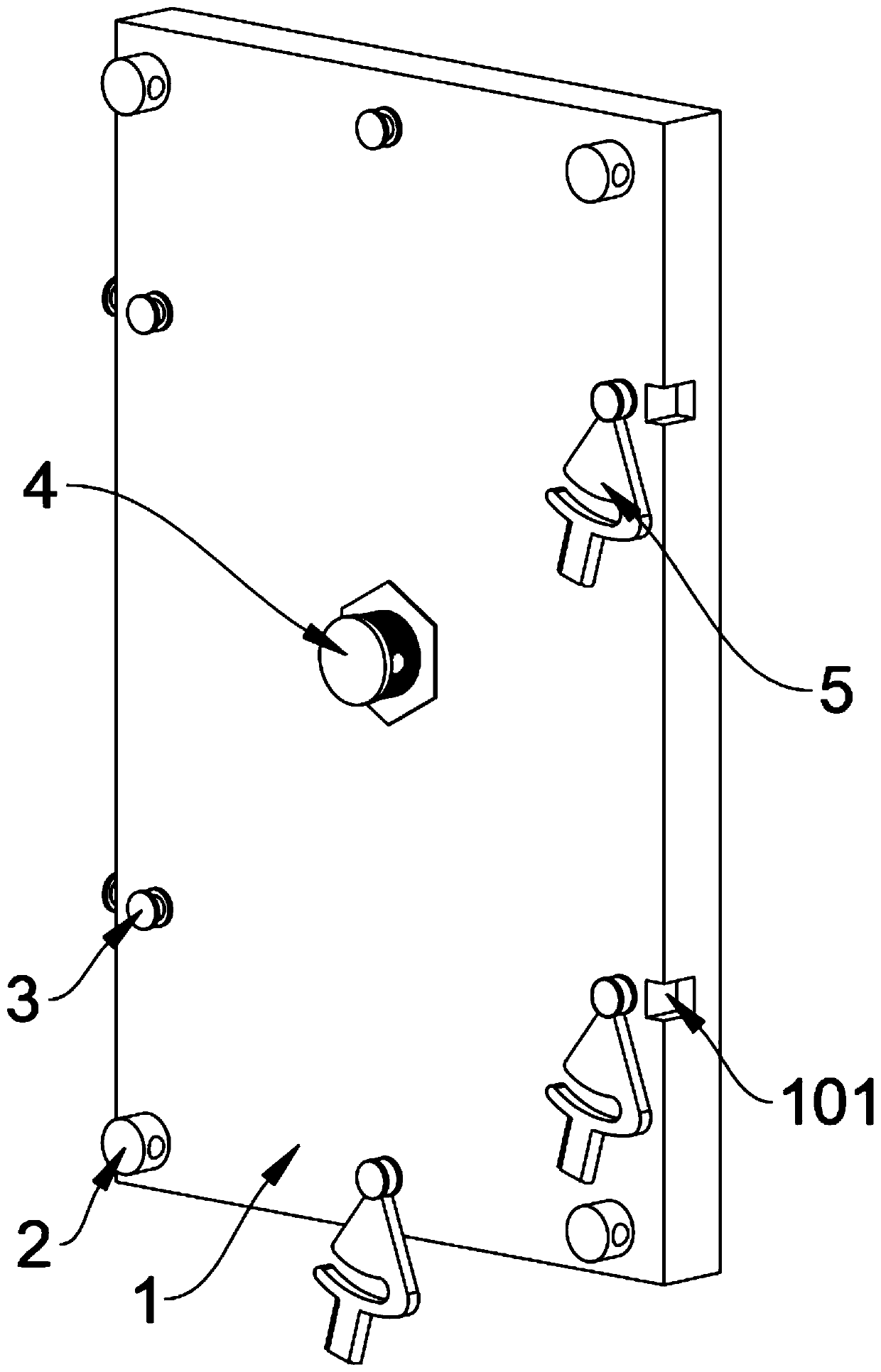

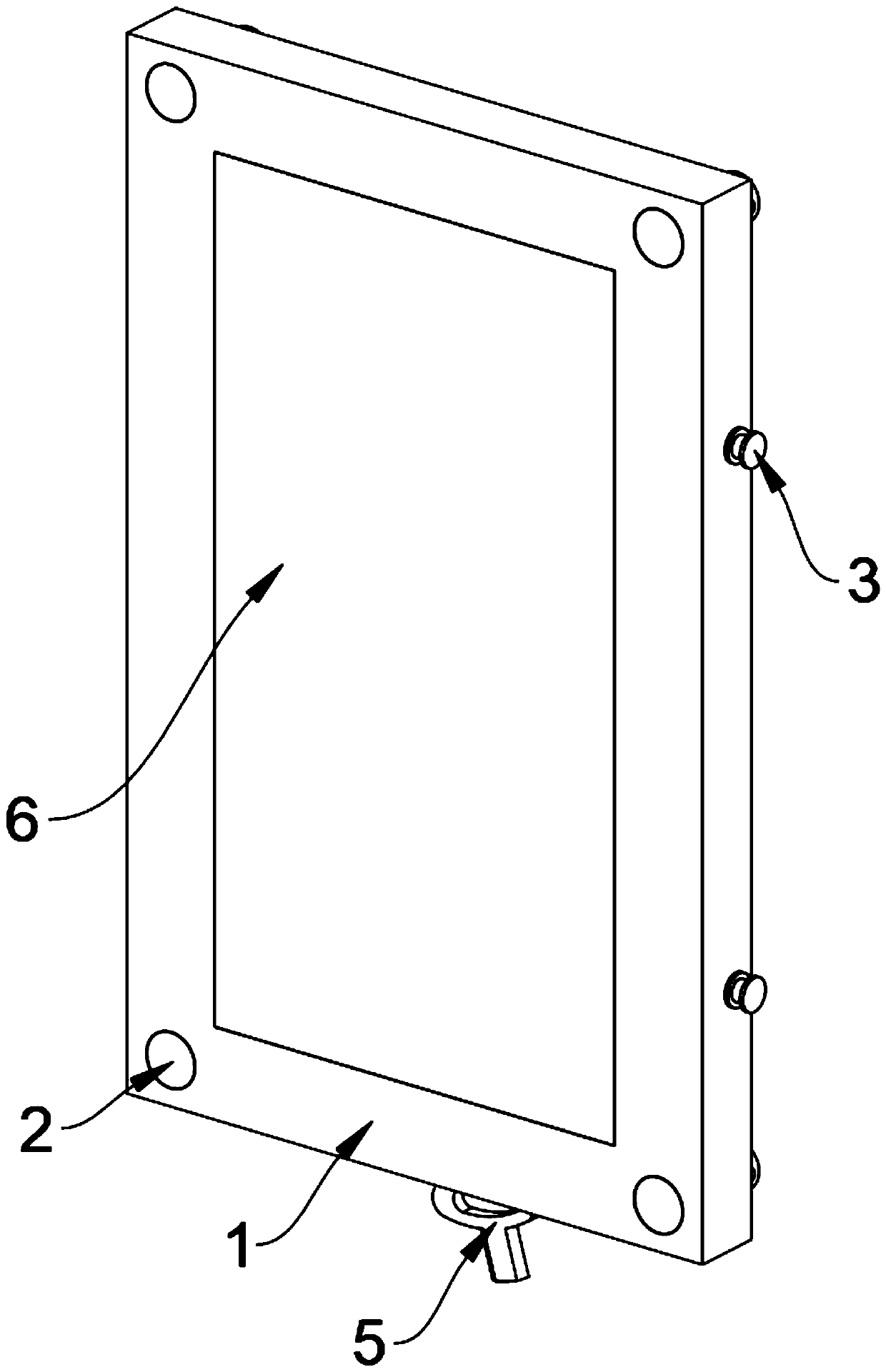

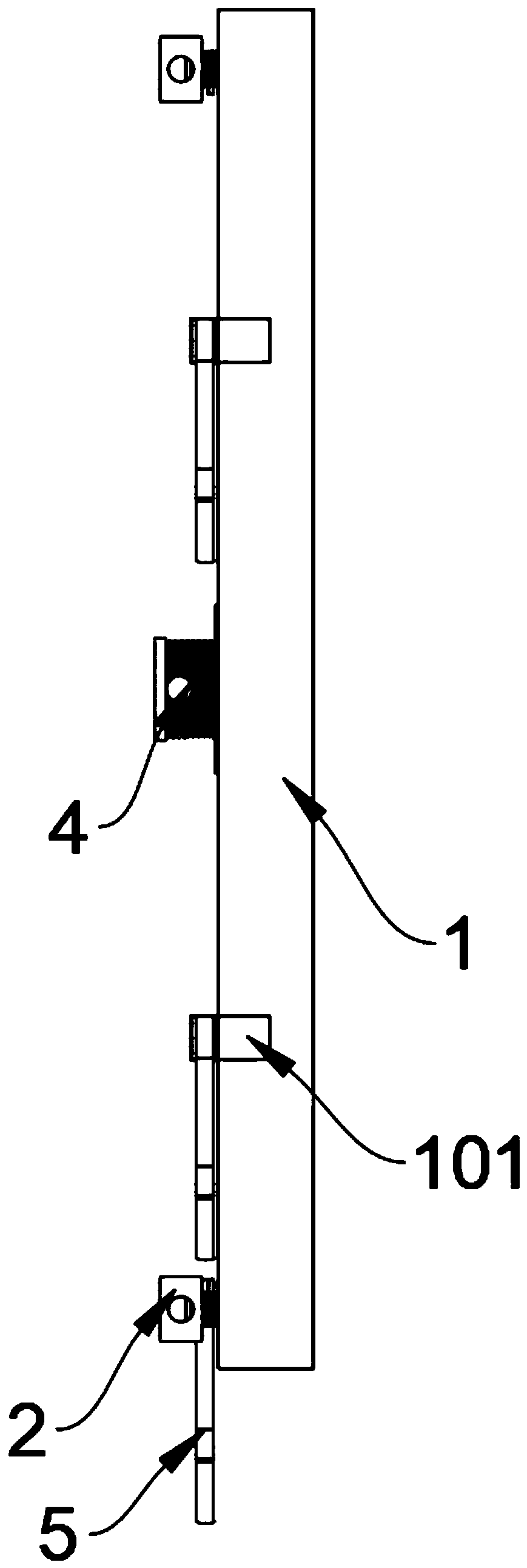

[0039] as attached figure 1 To attach Figure 8 Shown:

[0040] The present invention provides a combined high-rise building formwork that is easy to demould, comprising: formwork main body 1; The middle position is provided with a threaded structure matching the middle ejection stud 4, the middle position of the formwork body 1 is threaded with the middle ejection stud 4, and the inner end of the middle ejection stud 4 is rotated to be provided with The middle ejector plate 6 facilitates the ejection operation of the middle ejector plate 6 through the rotation of the middle ejector stud 4, so that the four sides of the formwork main body 1 can be separated from the concrete through the ejection of the middle ejector plate 6, thereby assisting The rapid demoulding operation of the template; the four corners of the template main body 1 are screwed and fixed with a four-corner ejector 2, and the front side of the four-corner ejector 2 is provided with a circular ejector block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com