Patents

Literature

80results about How to "Fixed effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

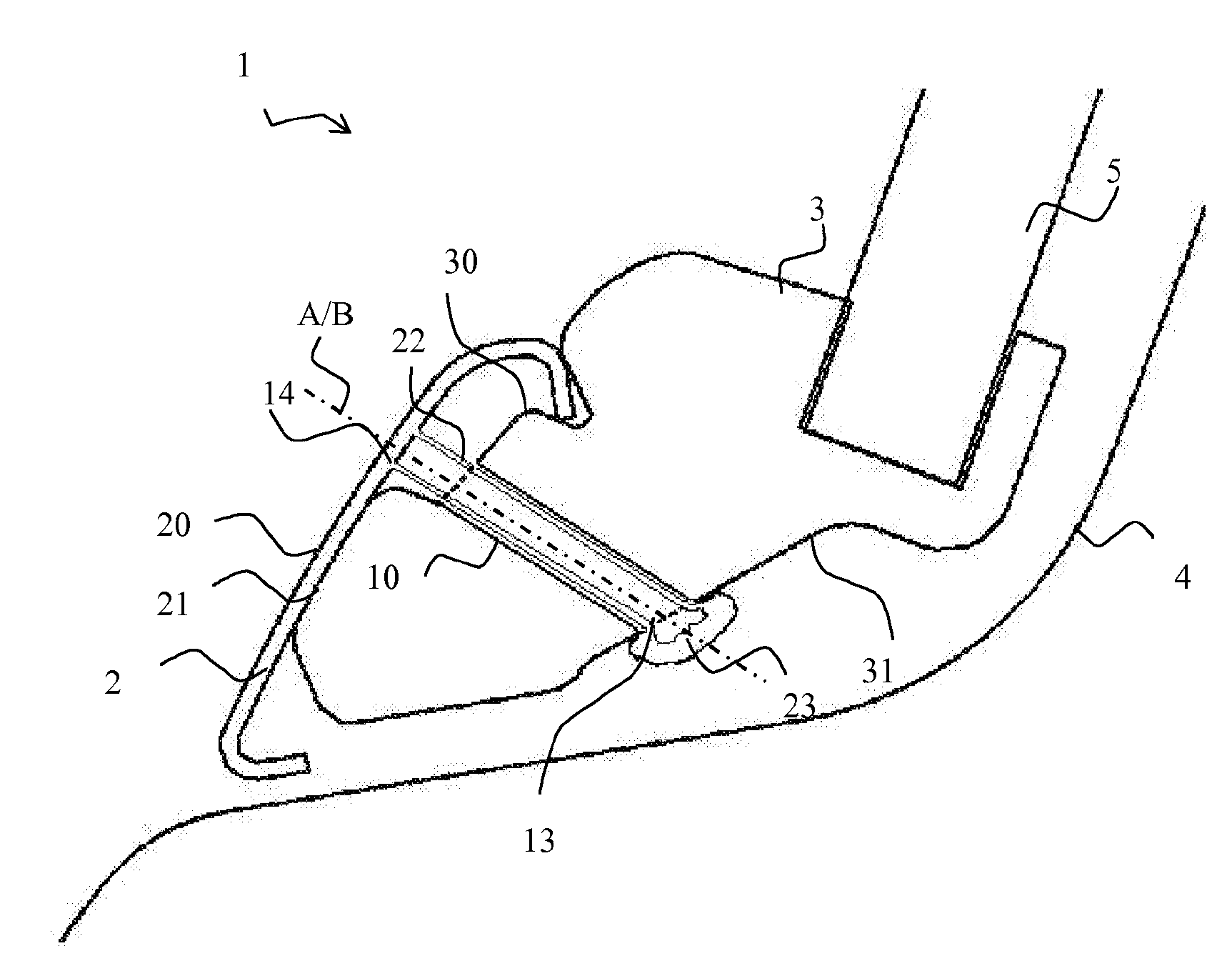

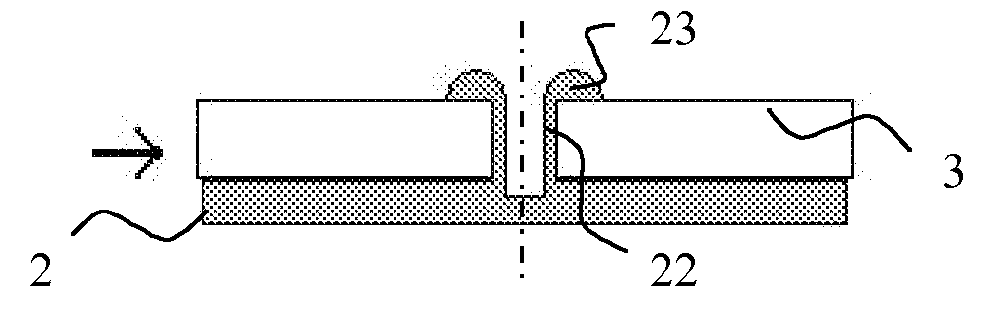

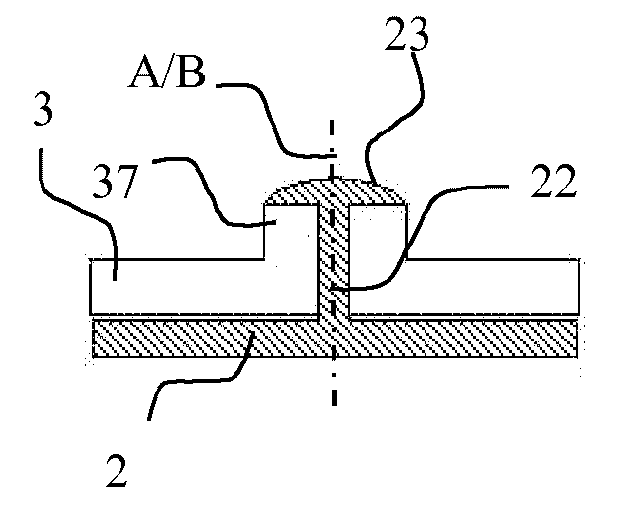

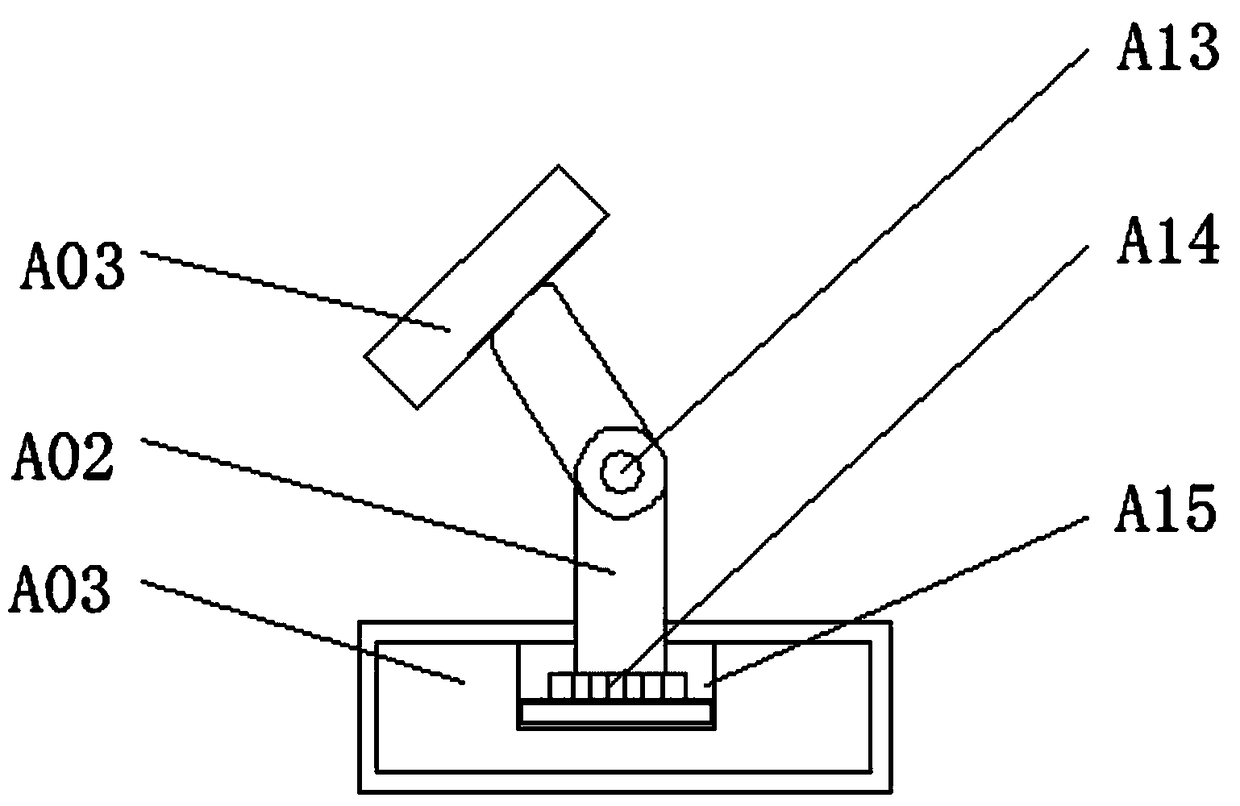

Method for fixing an additional part to a glazing or a profiled rim, fixing device for fixing said part, and glazing obtained by said method

ActiveCN102666071AEasy to pass throughEasy to operateEngine sealsVehicle sealing arrangementsPlastic materialsStructural engineering

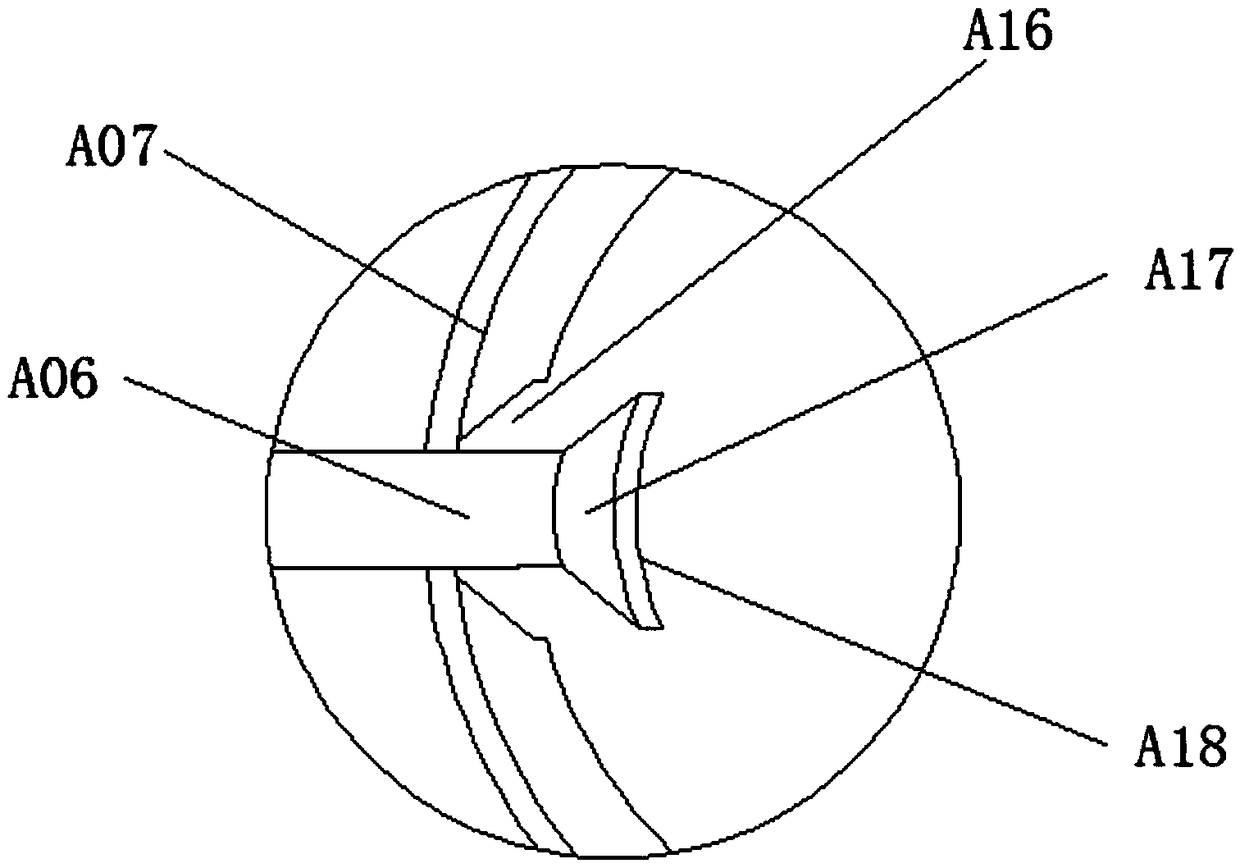

The invention relates to a method for fixing an additional part (2) consisting of a plastic material, such as a decorative cover, to the periphery of a glazing (1) and especially to part of a profiled rim (3) fixed to the periphery of the glazing (1), said additional part (2) having a rear face (21) comprising fixing means for fixing to said glazing (1) or said profiled rim (3). The invention is characterised in that the rear face (21) comprises a plurality of appendices (22, 22') that each penetrate into a hole (10, 10') in said profiled rim (3) or said glazing (1), and protrude at the two ends thereof onto two respectively opposite faces of the profiled rim (3) or the glazing (1), the distal end (23, 23') of each appendix protruding past a rear face (31) respectively of said profiled rim or said glazing defining the hole (10, 10'), and in that each distal end (23, 23') of each appendix is deformed by a temporary softening, preferably by the application of ultrasounds, in order to come into contact with the rear face (31) of said profiled rim or said glazing at the periphery of the hole (10, 10') and preferably over the entire periphery of the hole (10, 10').

Owner:SAINT-GOBAIN GLASS FRANCE

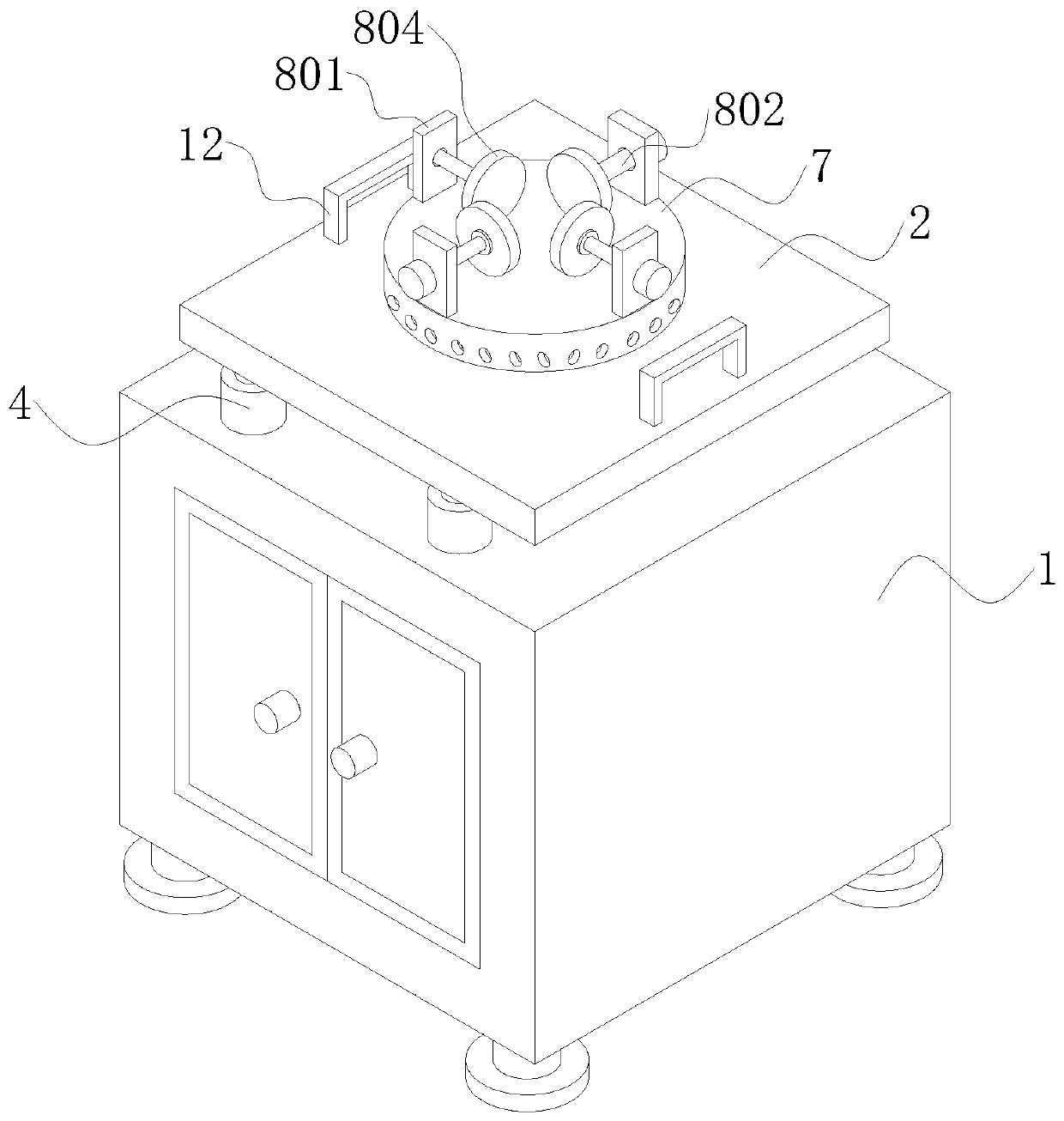

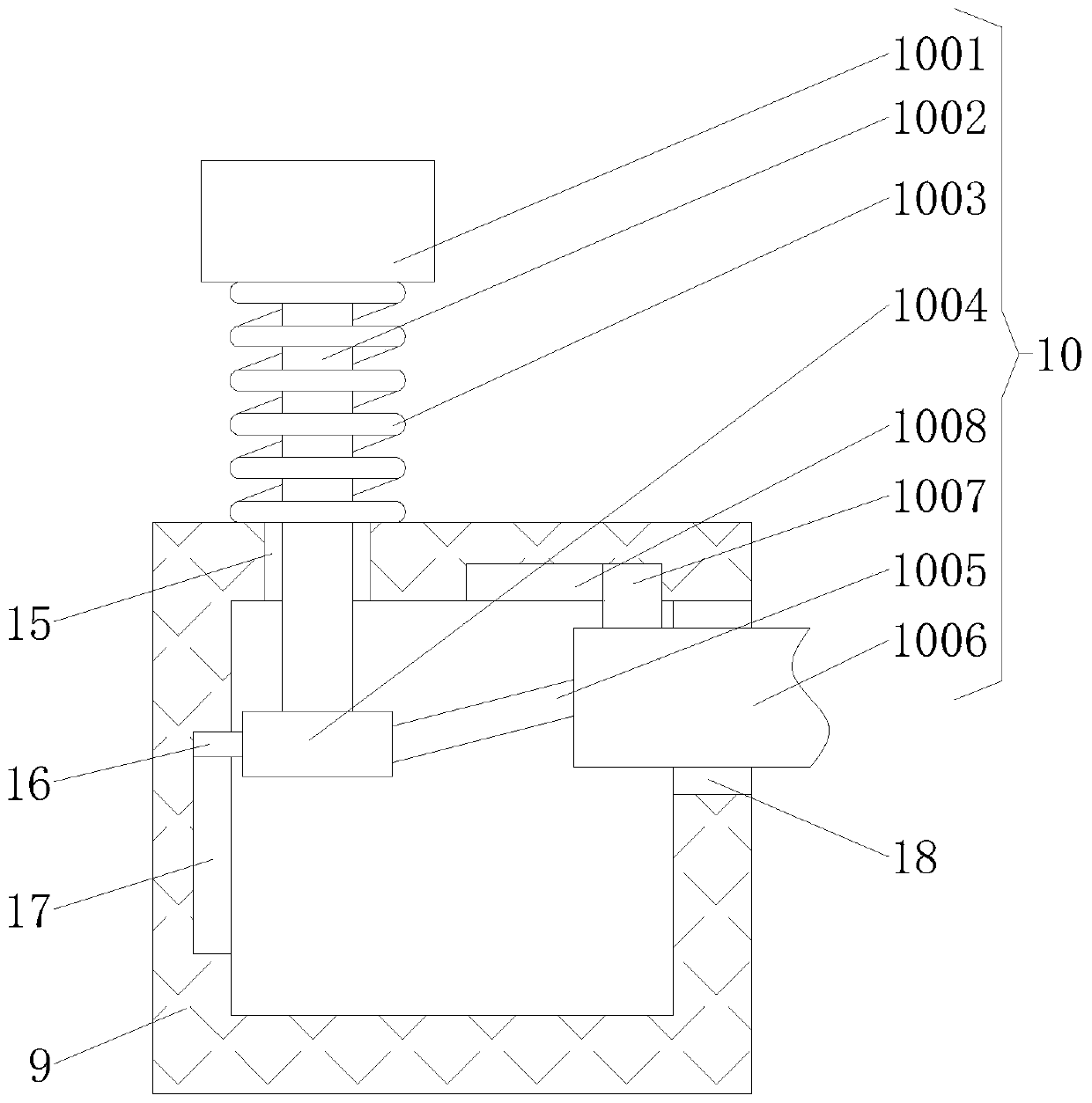

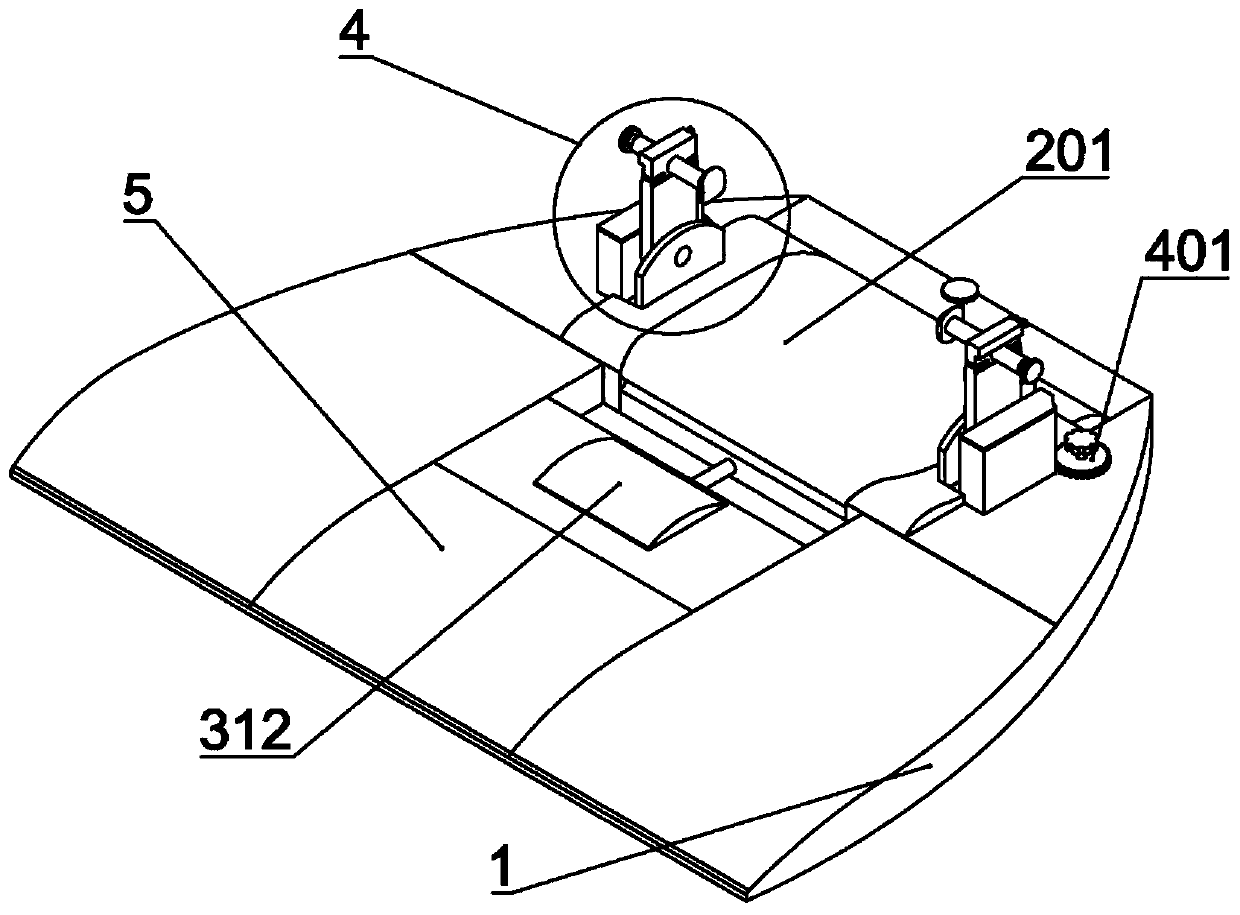

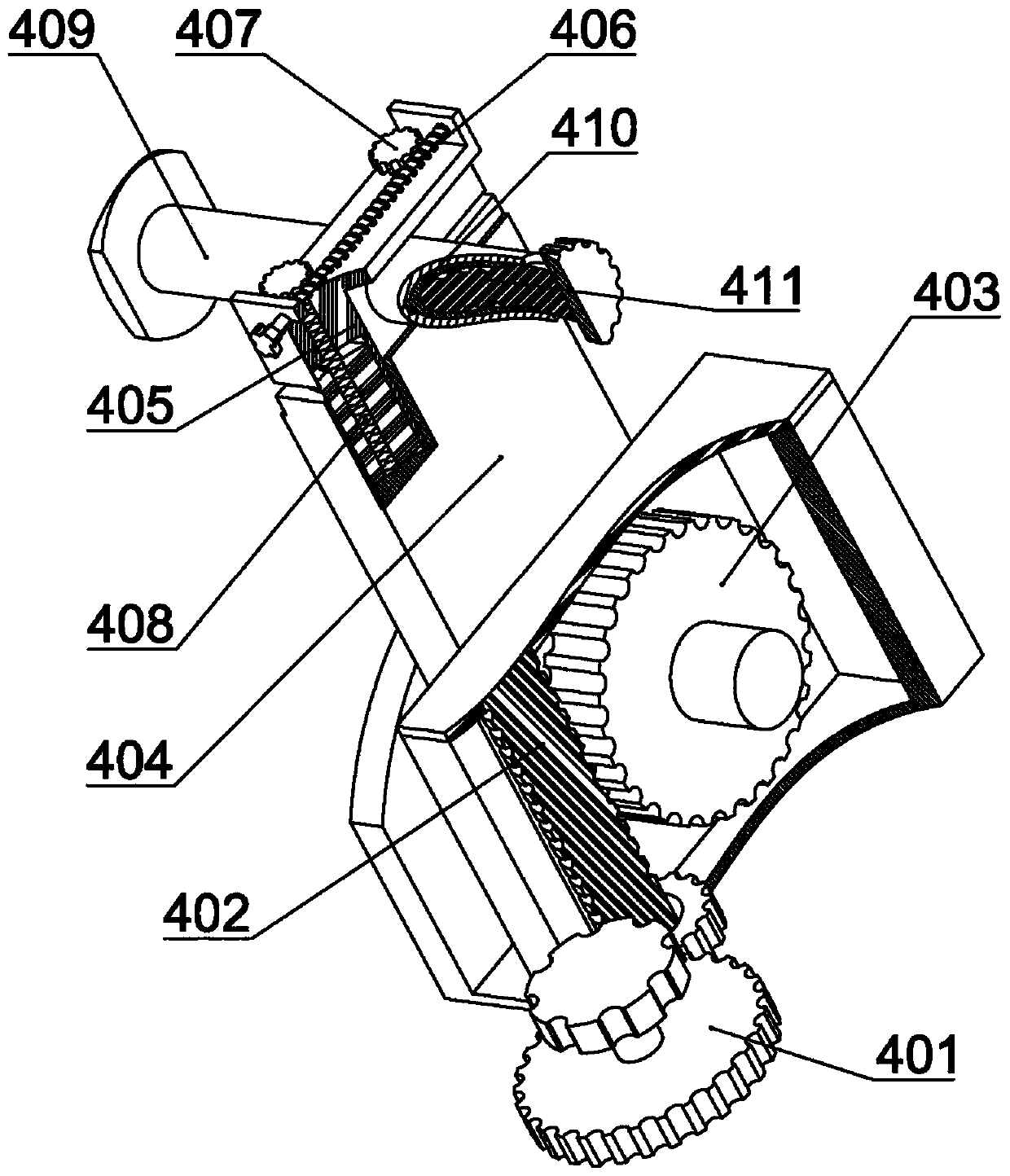

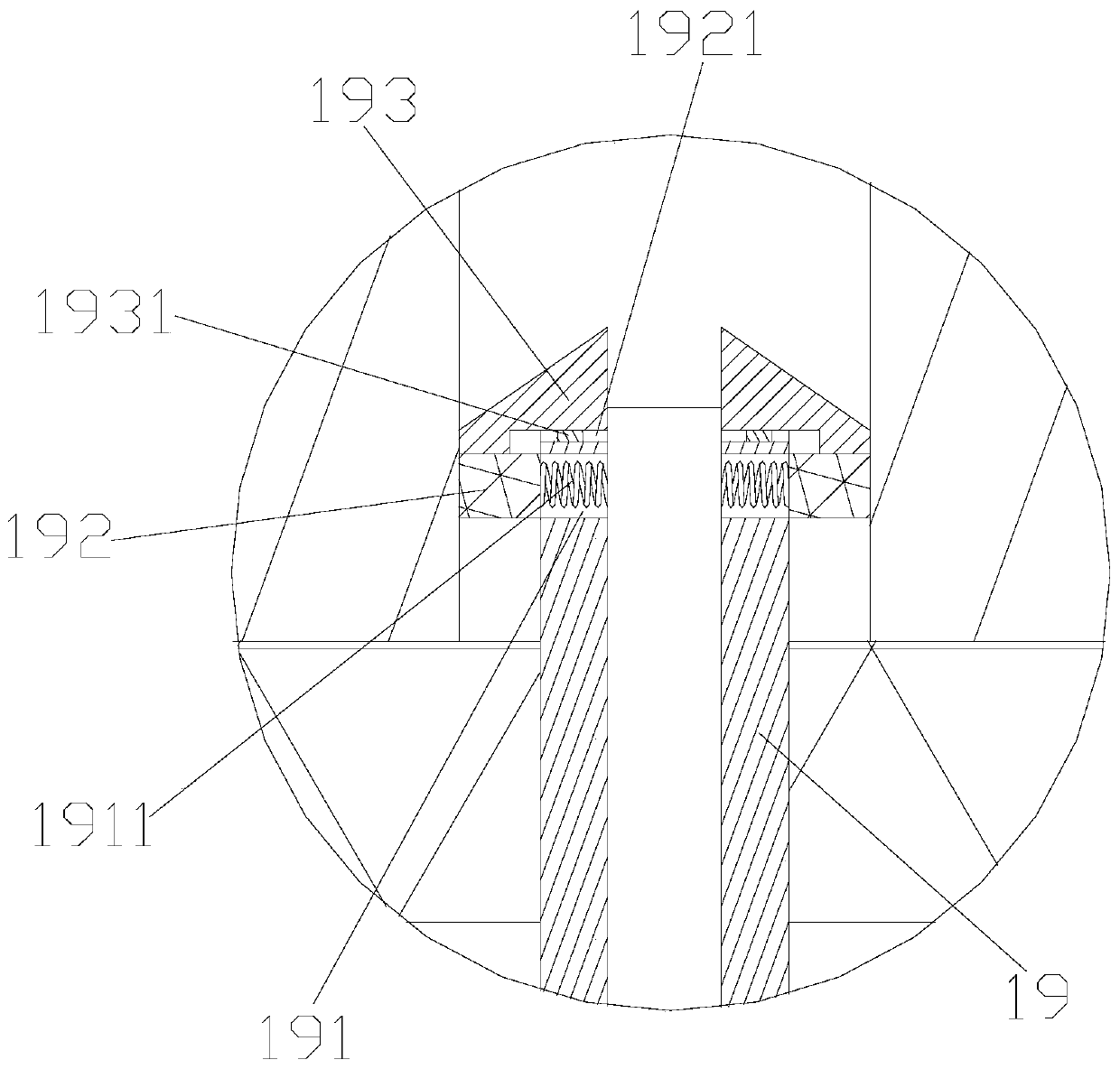

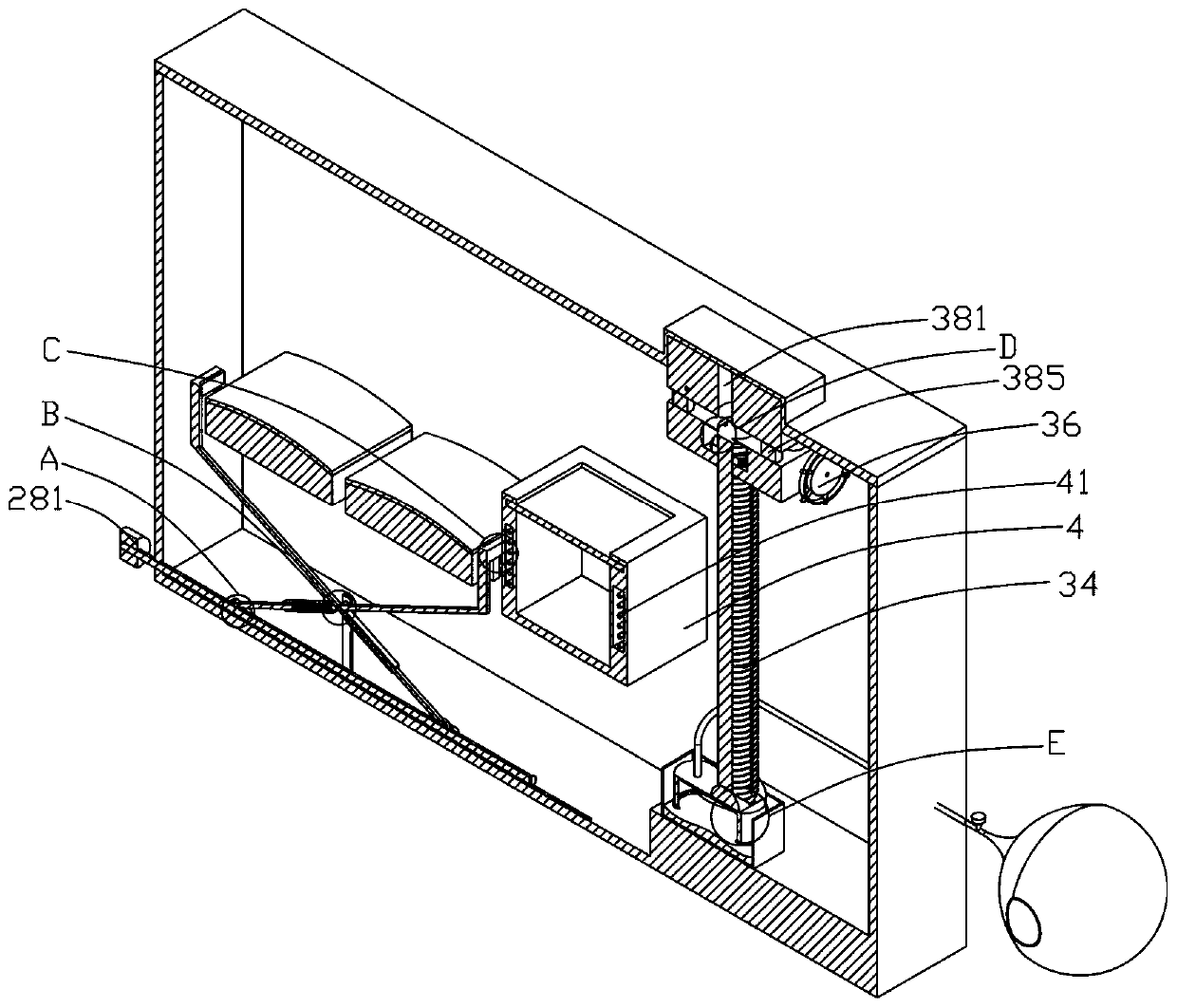

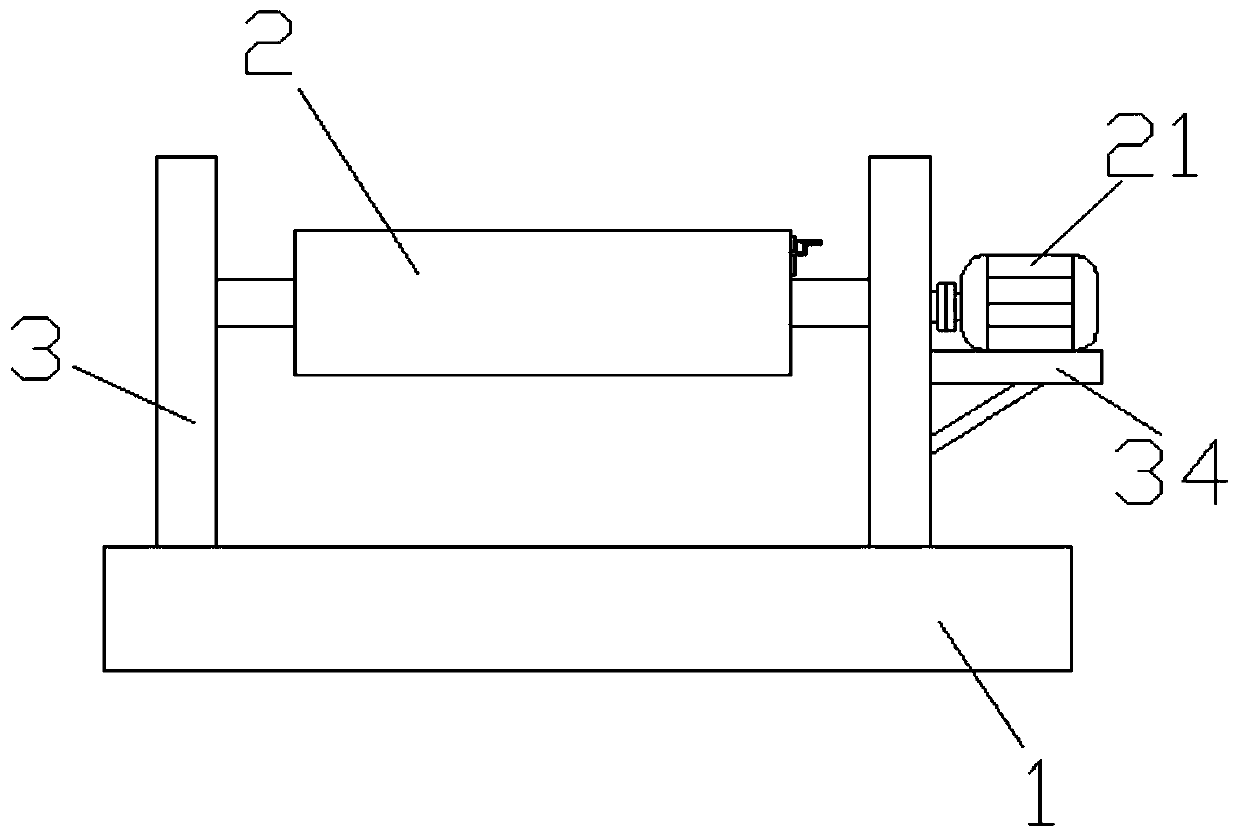

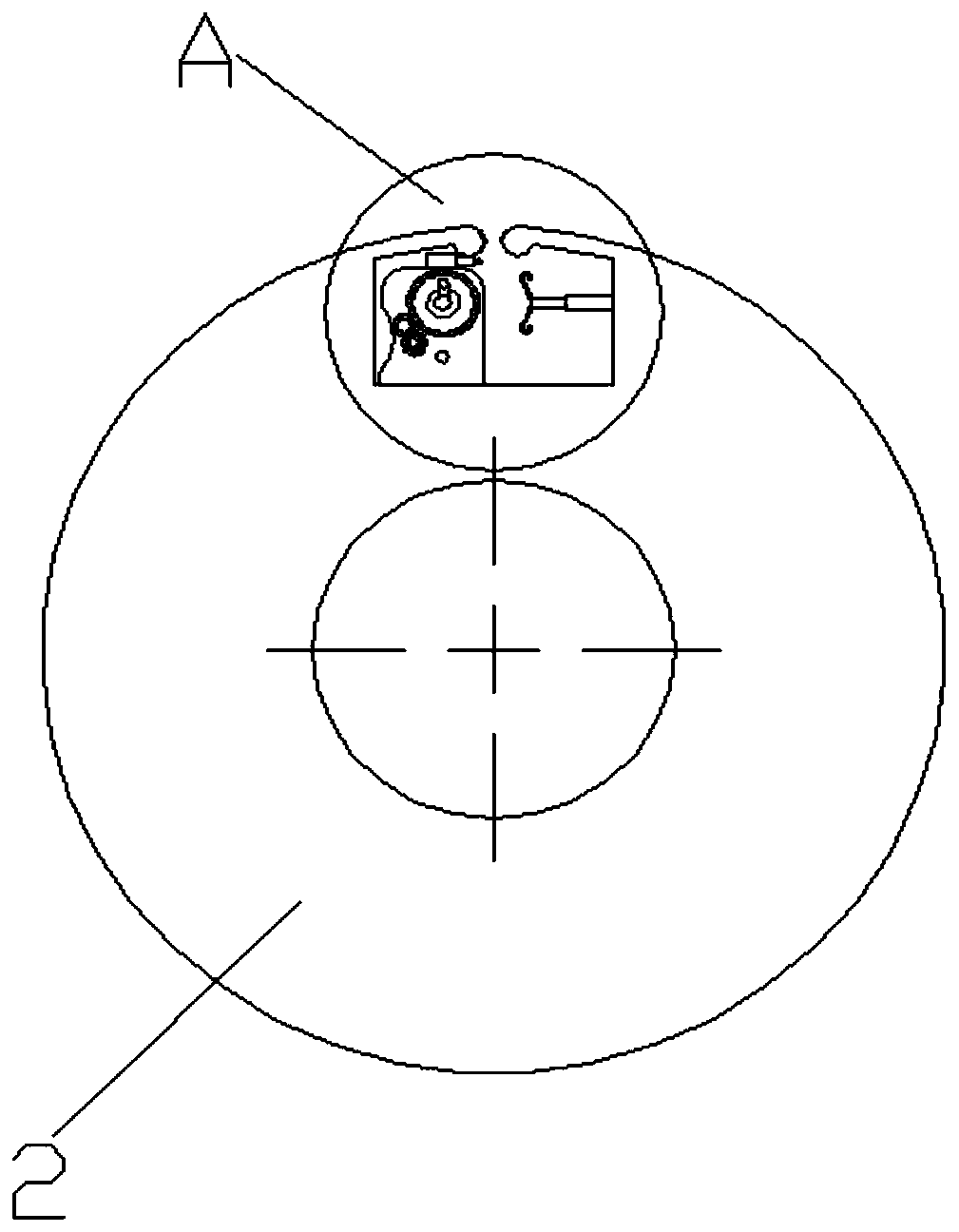

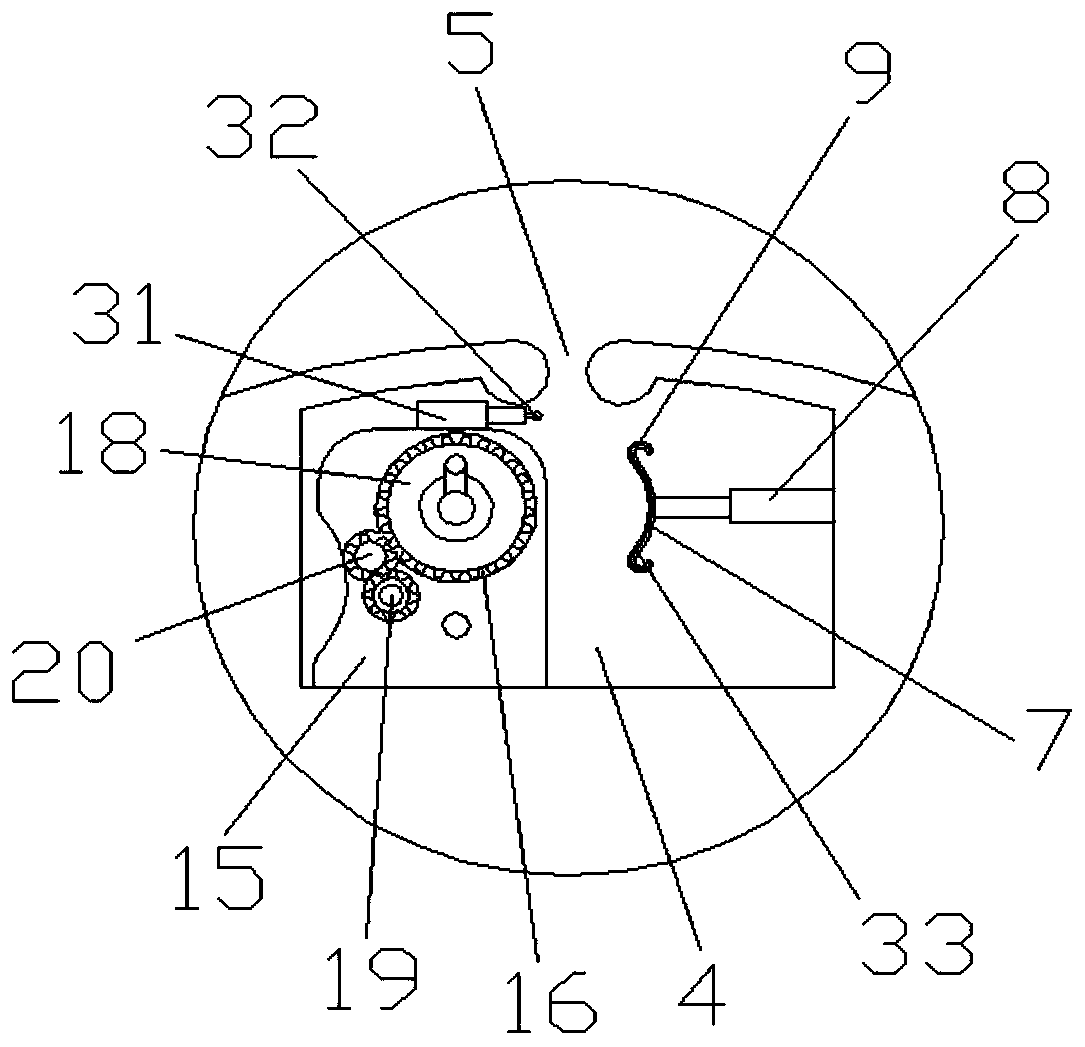

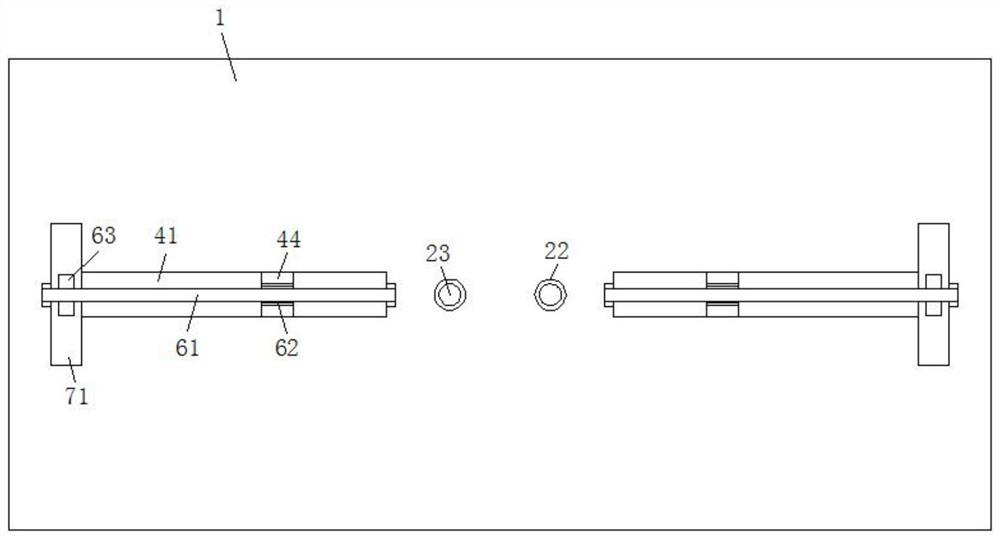

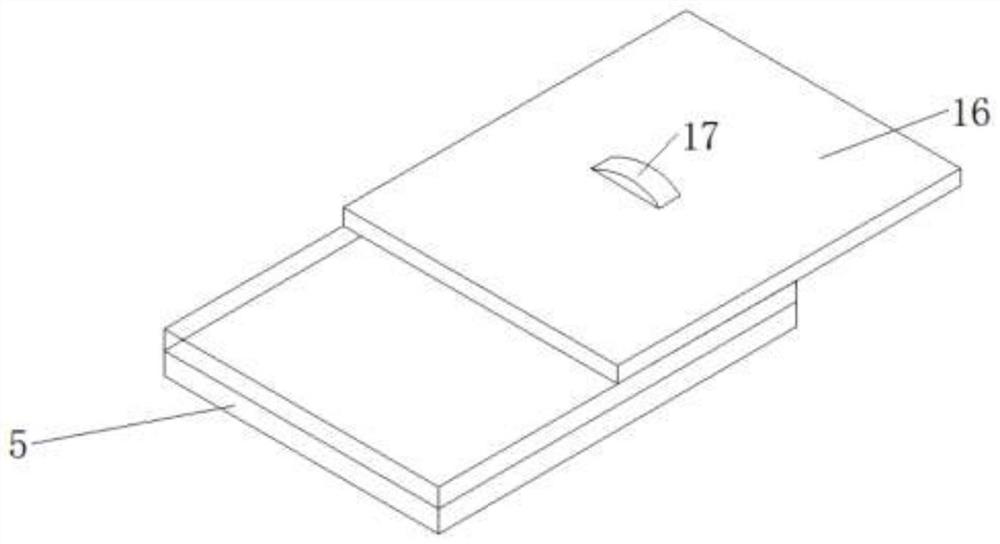

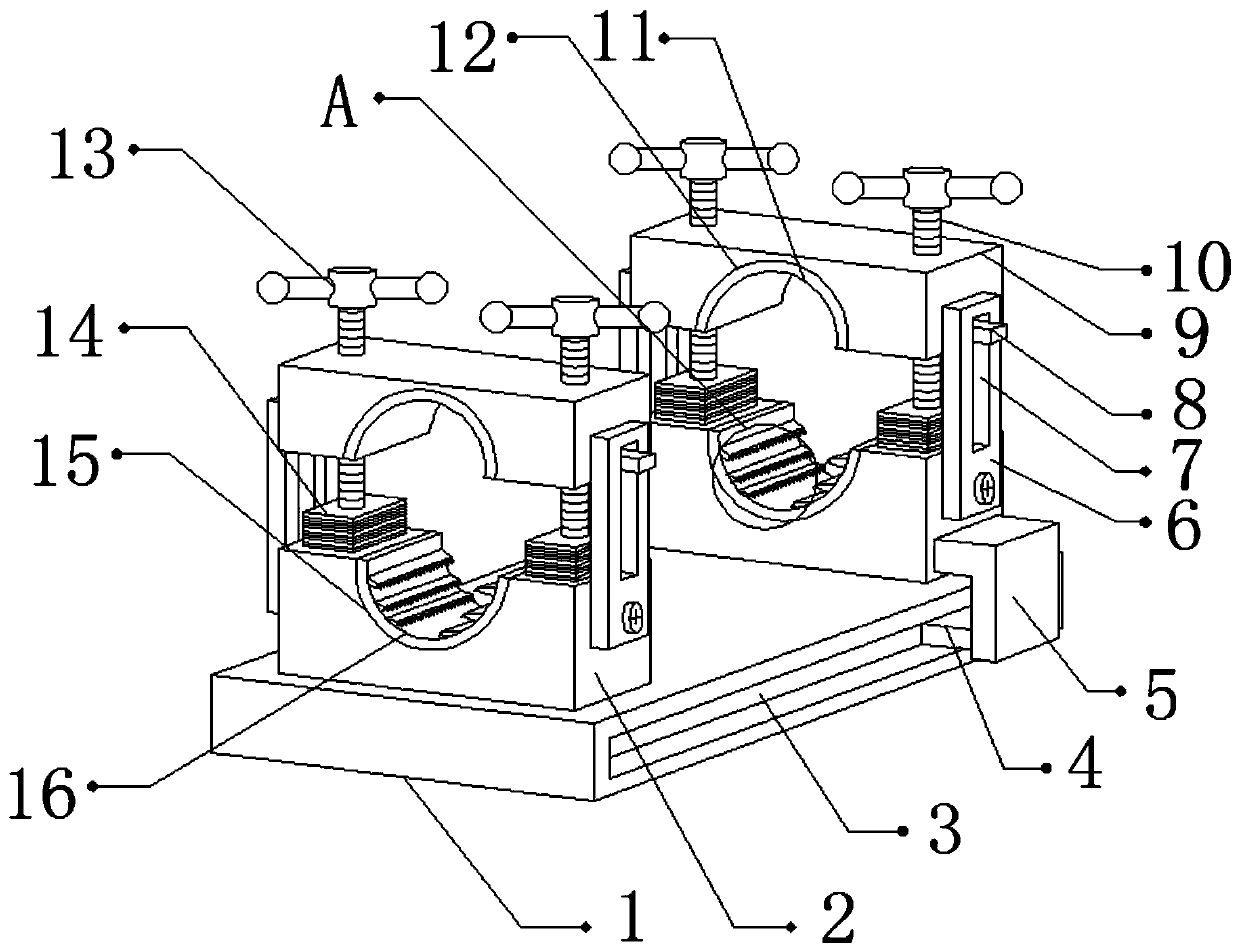

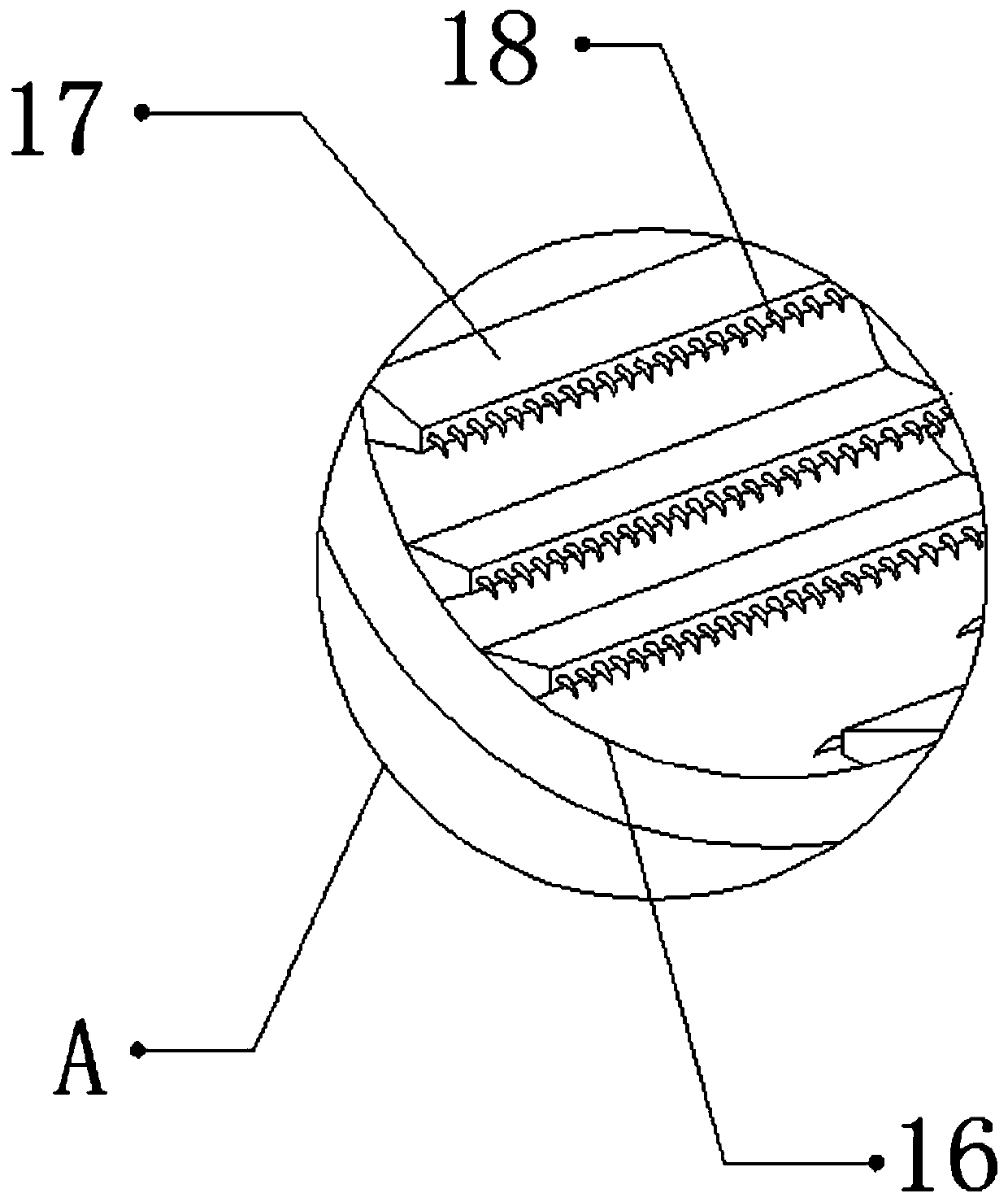

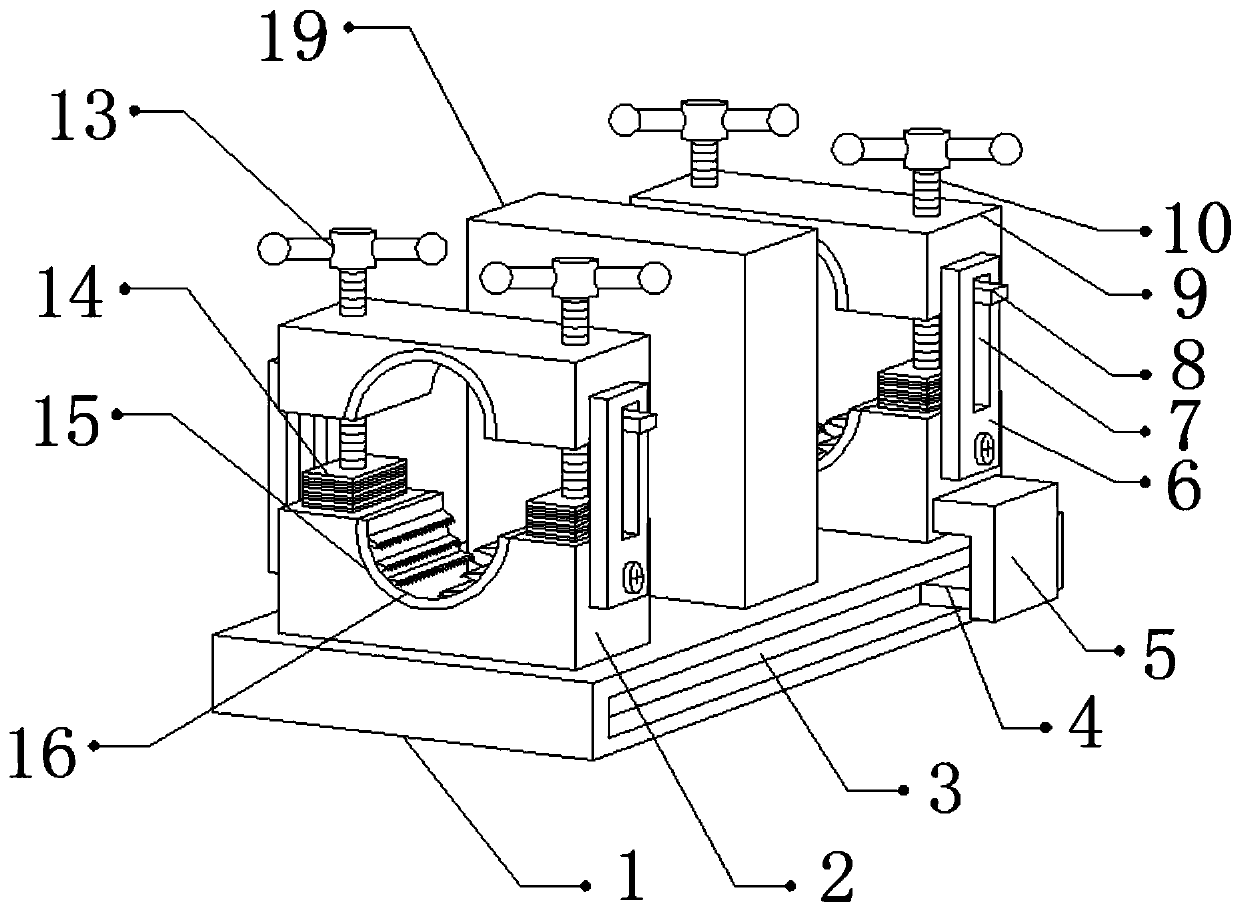

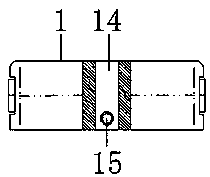

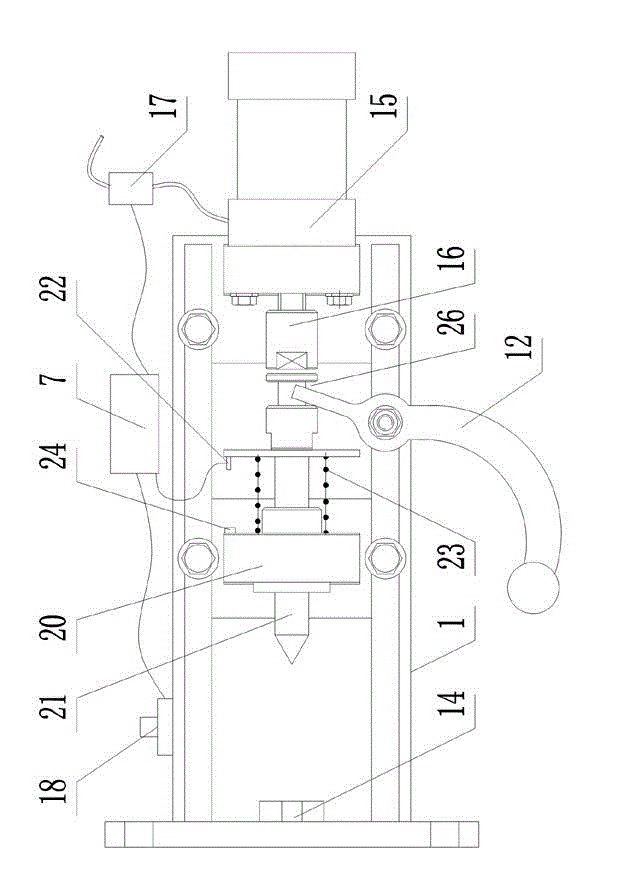

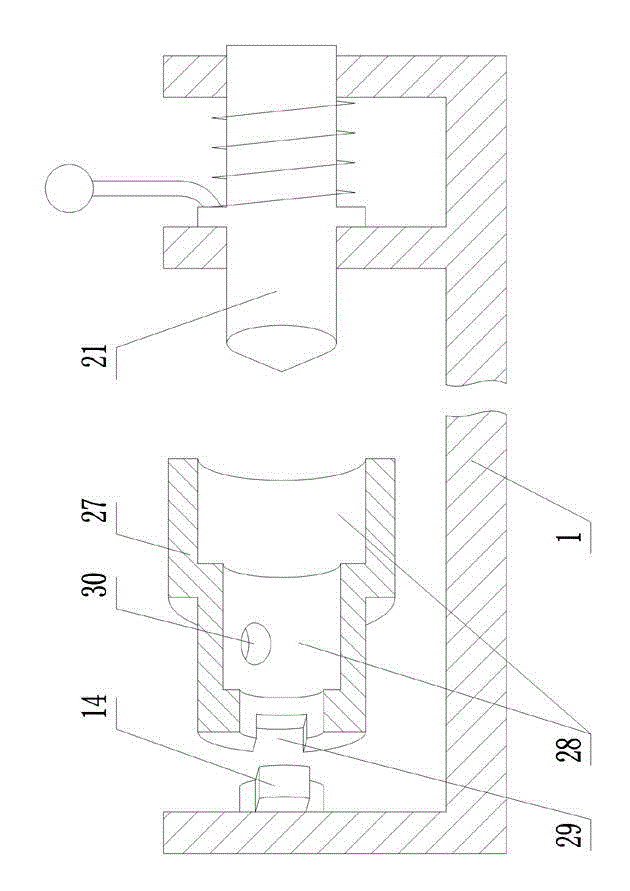

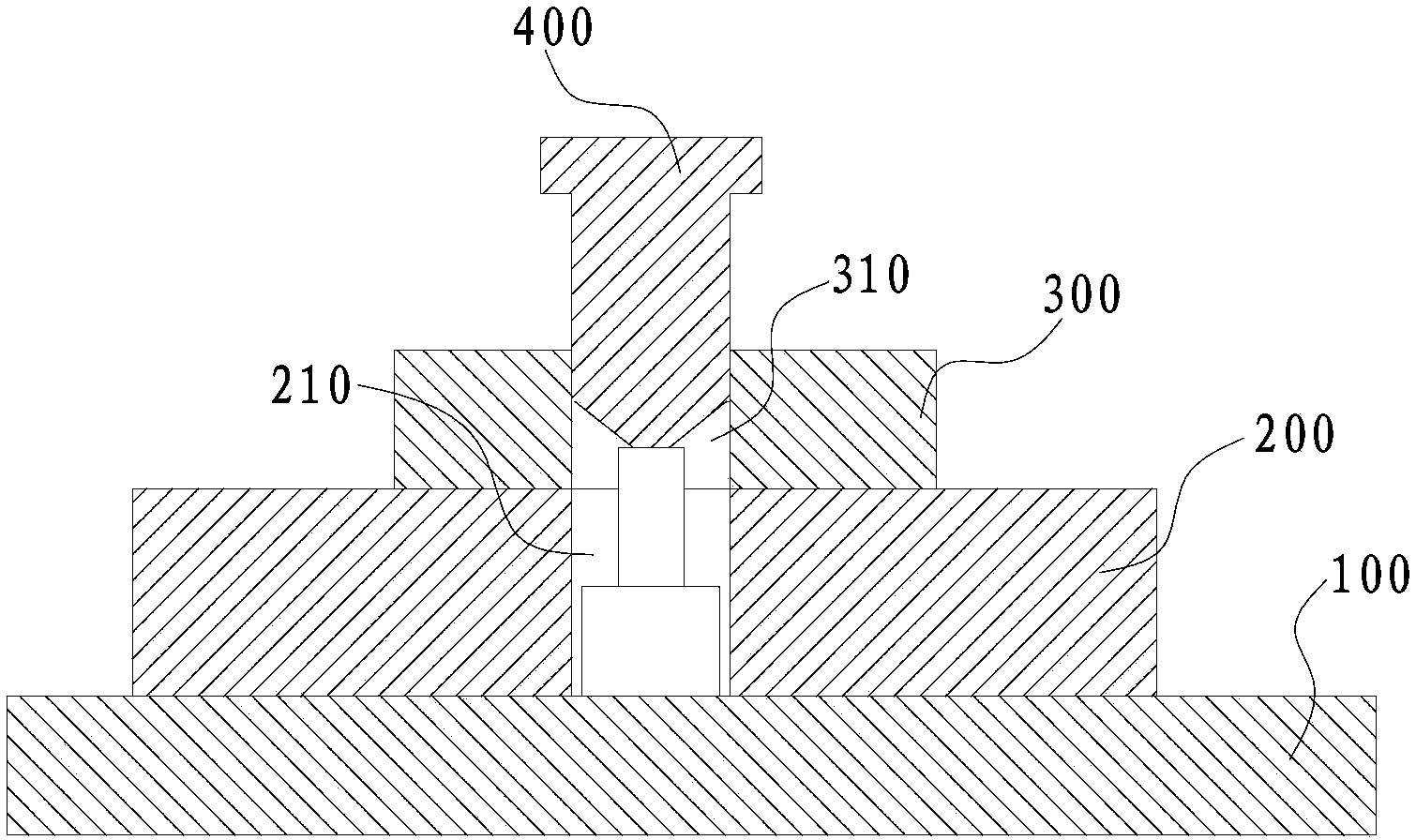

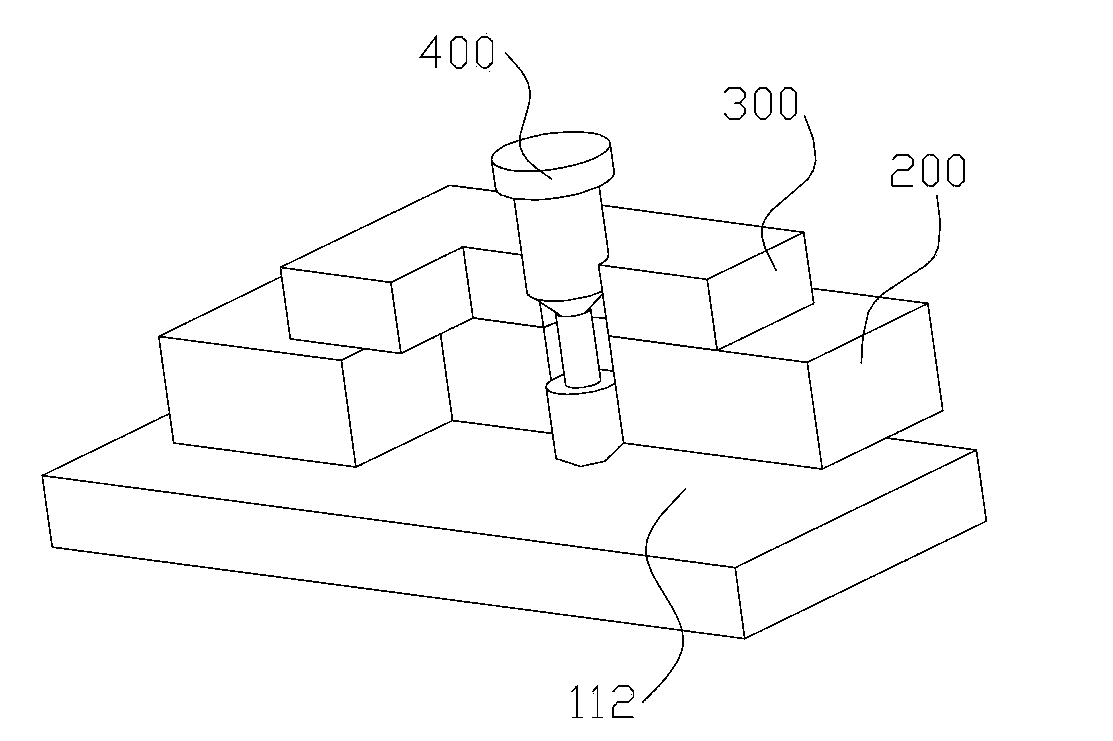

Mold machining device achieving precise locating

InactiveCN111515879AEasy to useUse, solve the problem that the existing mold processing device is not convenient to useWork holdersWork benchesWorkbenchMachining

The invention discloses a mold machining device achieving precise locating. The mold machining device comprises a workbench. A fixed plate is arranged at the top of the workbench. Locating blocks arefixedly connected to the bottom of the fixed plate. The bottoms of the locating blocks are sleeved with locating sleeves. Locating grooves used in cooperation with the locating blocks are formed at the tops of the locating sleeves. According to the mold machining device, through cooperative use of the workbench, the fixed plate, the locating blocks, the locating sleeves, the locating grooves, a moving rod, a moving plate, fixed mechanisms, a shell, a locating mechanism, a clamp groove, a handle, a moving wheel, an annular groove, a through hole, a limiting block, a limiting groove and a through opening, the problems that an existing mold machining device is inconvenient for users to use, the position of a mold needs to be fixed multiple times in the use process, a large quantity of time and energy of users are consumed, consequently, use of users is influenced, and the work efficiency of users is reduced are solved; and the mold machining device achieving precise locating has the advantage of being convenient for users to use and is worthy of popularization.

Owner:宁波引智信息科技有限公司

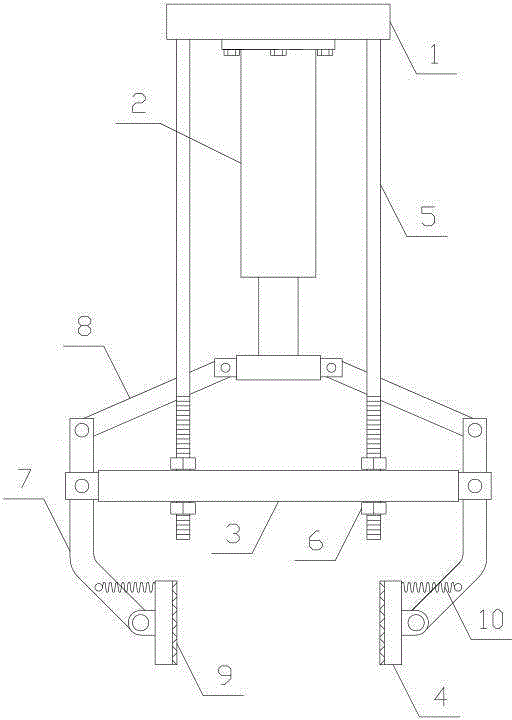

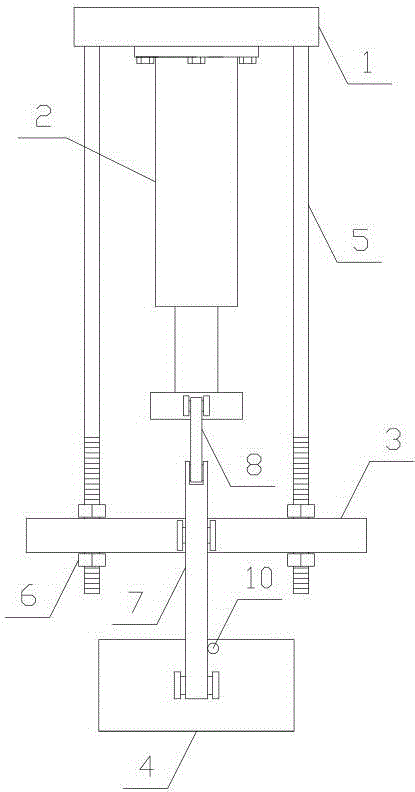

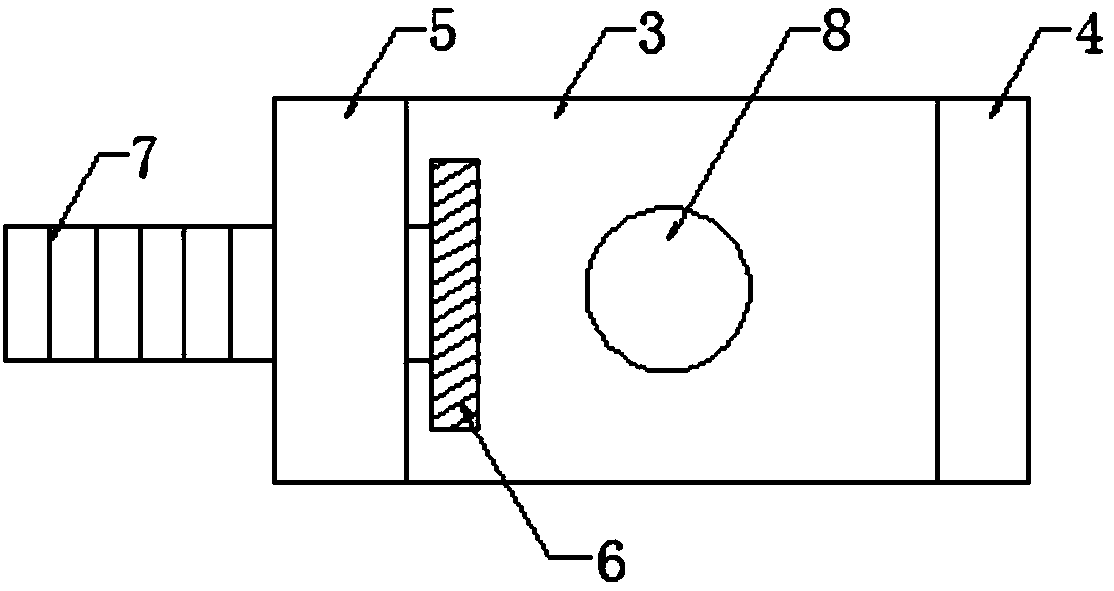

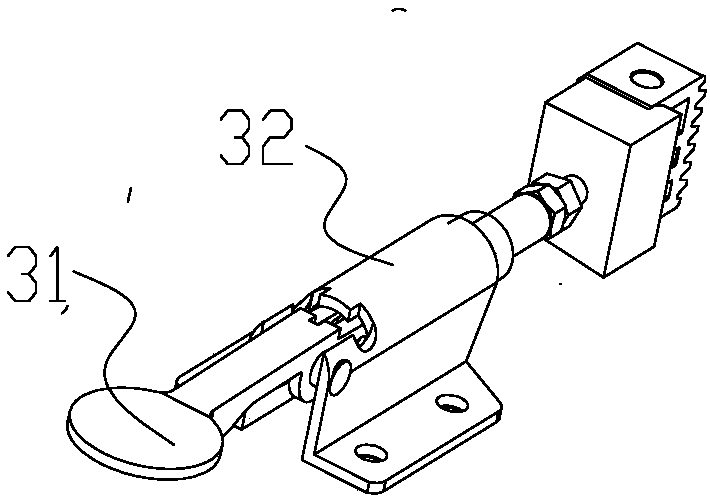

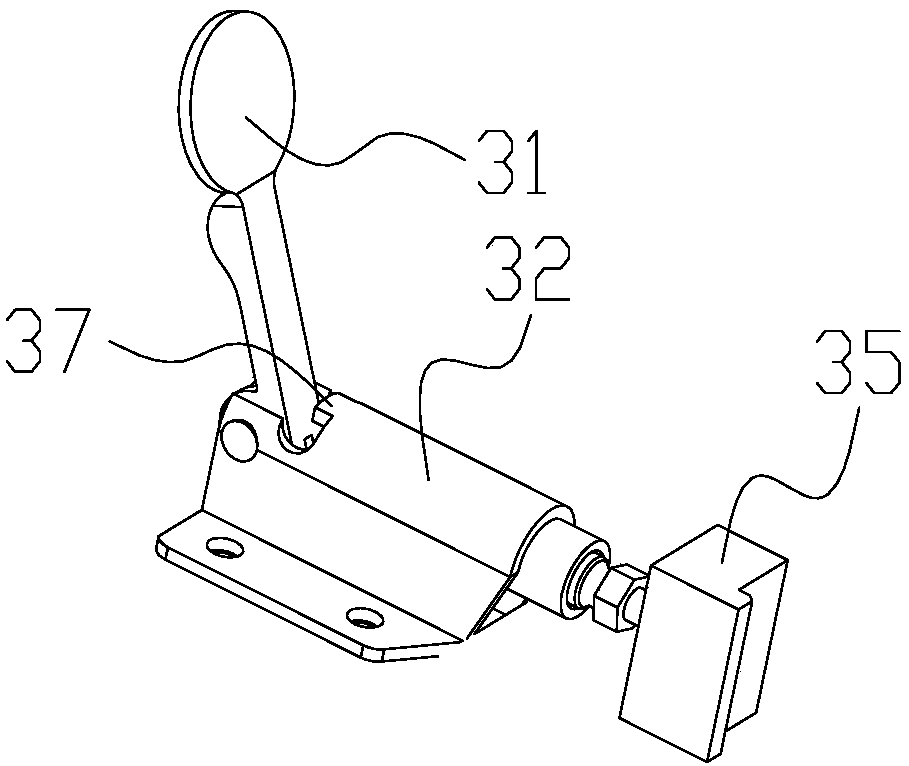

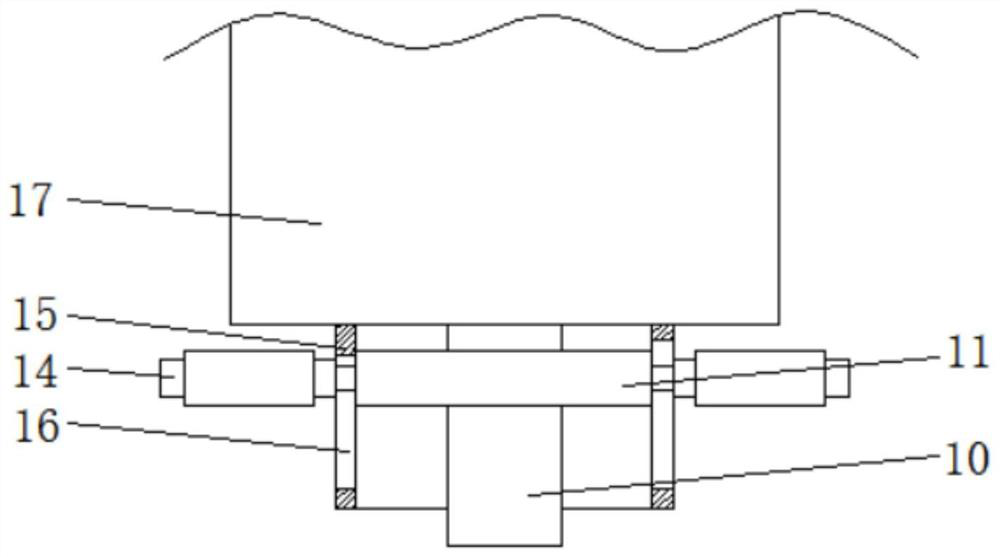

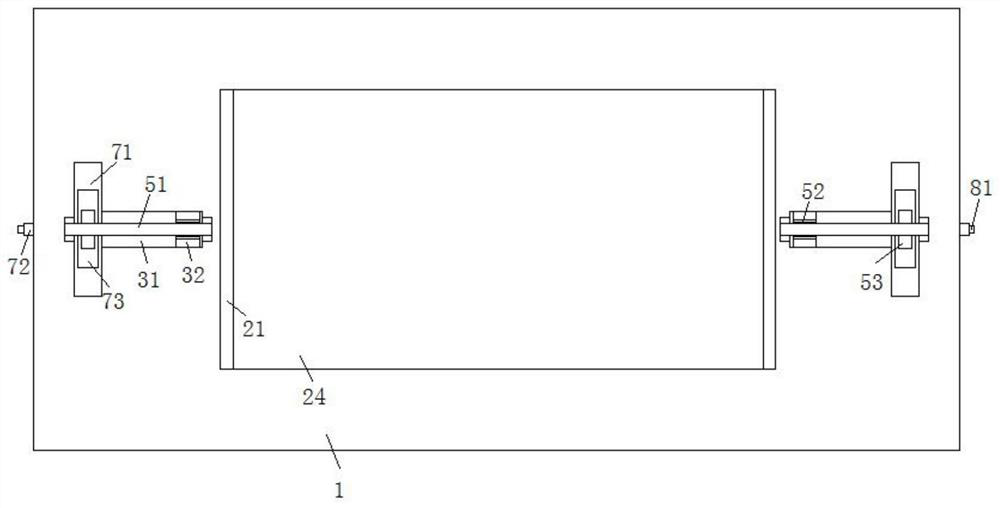

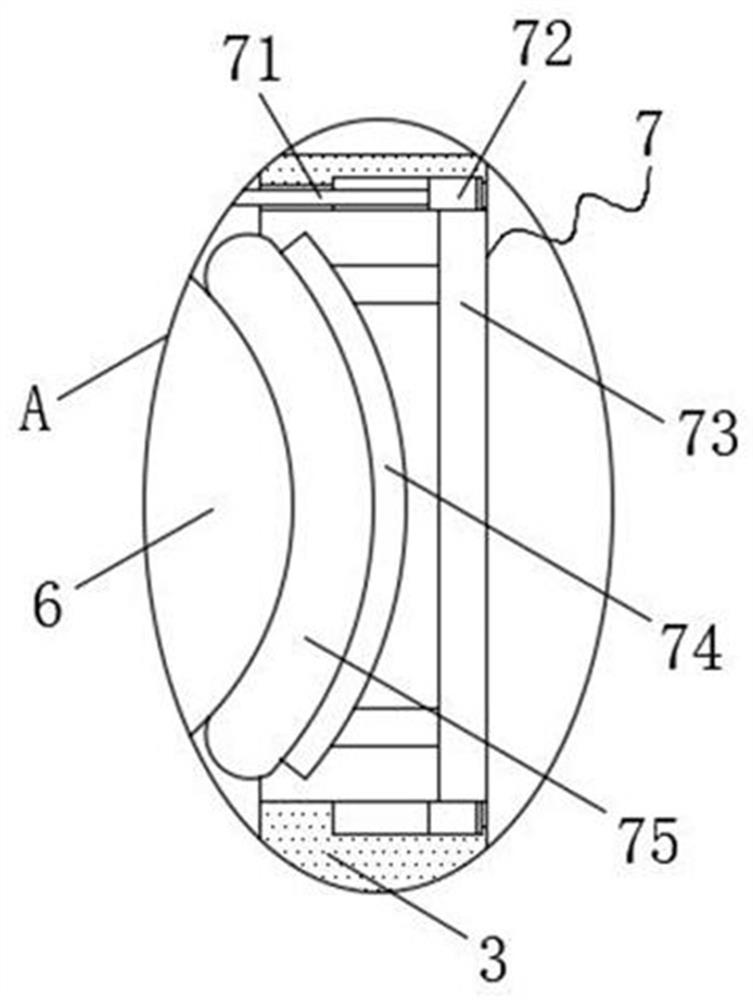

Packaging box clamping mechanism

The invention discloses a packaging box clamping mechanism and belongs to the field of package transfer equipment. The packaging box clamping mechanism comprises a fixing plate, a box clamping cylinder, a support plate and box clamping plates, wherein the box clamping cylinder is vertically downwards arranged in the middle of the lower side of the fixing plate; the support plate is horizontally arranged at the lower ends of adjusting screw rods; the adjusting screw rods vertically downwards penetrate through the support plate; adjusting nuts are in threaded connection with the adjusting screw rods on the upper side and the lower side of the support plate separately; connecting rods are arranged on two sides of the support plate separately; middle parts of the two connecting rods are hinged to the support plate; a drive rod is arranged between each connecting rod and the box clamping cylinder, one end of each drive rod is hinged with the upper end of the corresponding connecting rod, and the other end of each drive rod is hinged with the lower end of the box clamping cylinder; the box clamping plates are arranged at the lower ends of the connecting rods, and the middle part of one side of each box clamping plate is hinged with the lower end of the corresponding connecting rod. The packaging box clamping mechanism is simple in structure and can clamp and fix a packaging box rapidly, efficiently and conveniently, and demands of production and application are met.

Owner:蔡雁行

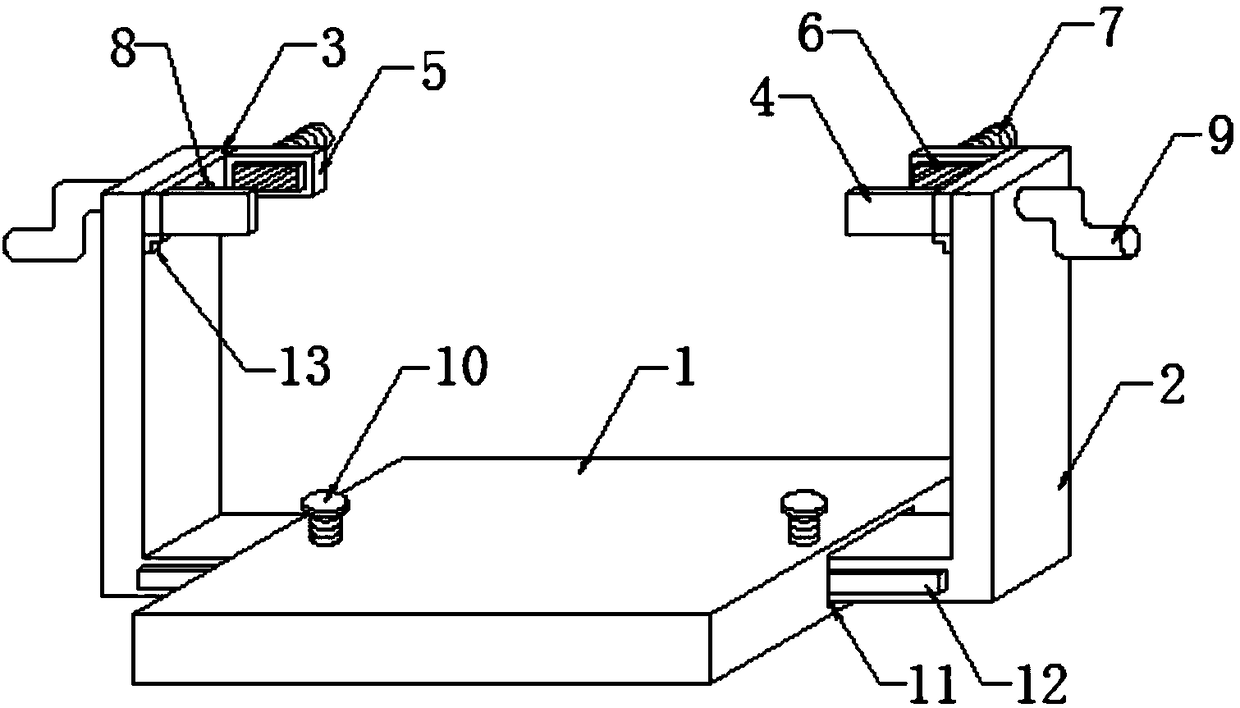

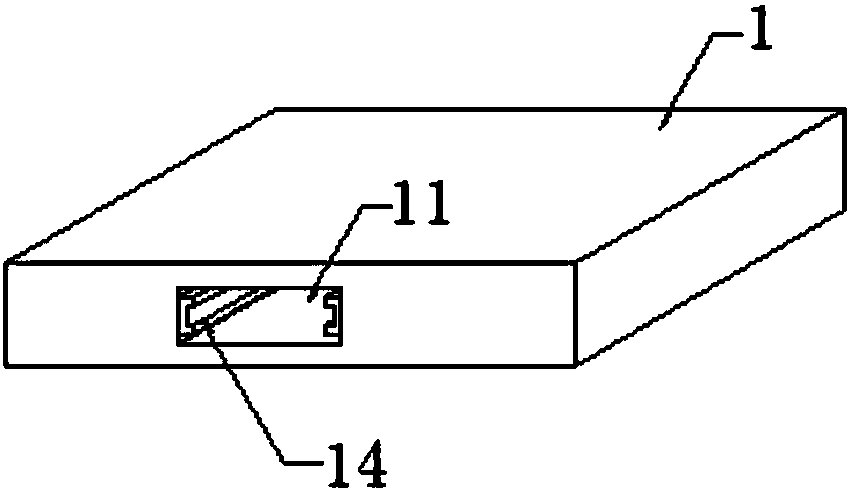

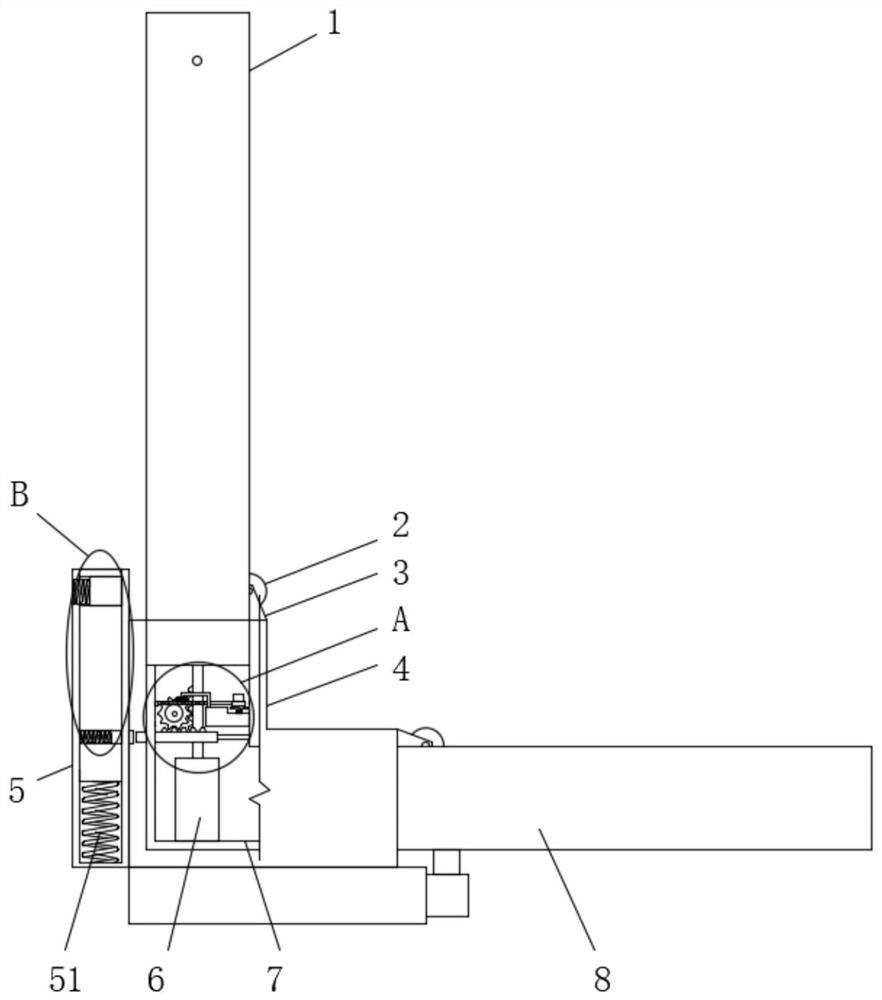

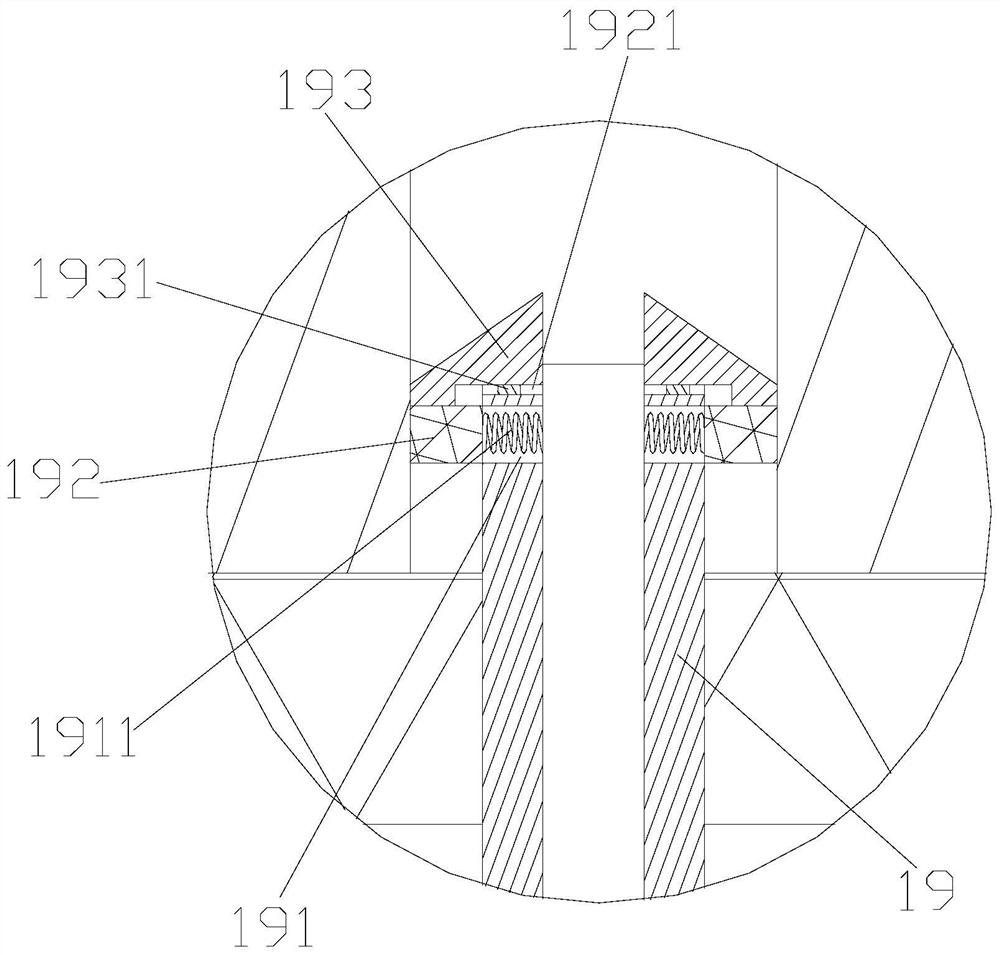

Convenient-to-disassemble supporting frame base with angle conversion function for assembly building

The invention discloses a convenient-to-disassemble supporting frame base with an angle conversion function for an assembly building, and belongs to the technical field of building assembly. The convenient-to-disassemble supporting frame base comprises a base body and a supporting plate, wherein the supporting plate is attached to the upper surface of the base body, a storage groove is formed in the upper surface of the supporting plate, a frame is arranged in the storage groove, an empty groove is formed in the lower surface of the inner wall of the storage groove, and a positioning mechanism is arranged in the empty groove. According to the convenient-to-disassemble supporting frame base, the positioning mechanism is arranged, when the frame is placed in the storage groove, a fixing plate enters the groove, at the moment, a triangular block can extrude two rollers, the two rollers drive two arc-shaped blocks to be far away from each other through two first sliding rods respectively, a baffle can rotate under the action of a pin shaft when being extruded by the arc-shaped blocks, at the moment, the baffle drives an extrusion roller to move to extrude a push plate, the push plate drives a sleeve to move, so that an inserting block can move and be inserted into an inserting groove, and at the moment, the frame can be effectively fixed.

Owner:温州艾米华农业科技有限公司

Repair tool for electronic production

Owner:天津富长盛科技有限公司

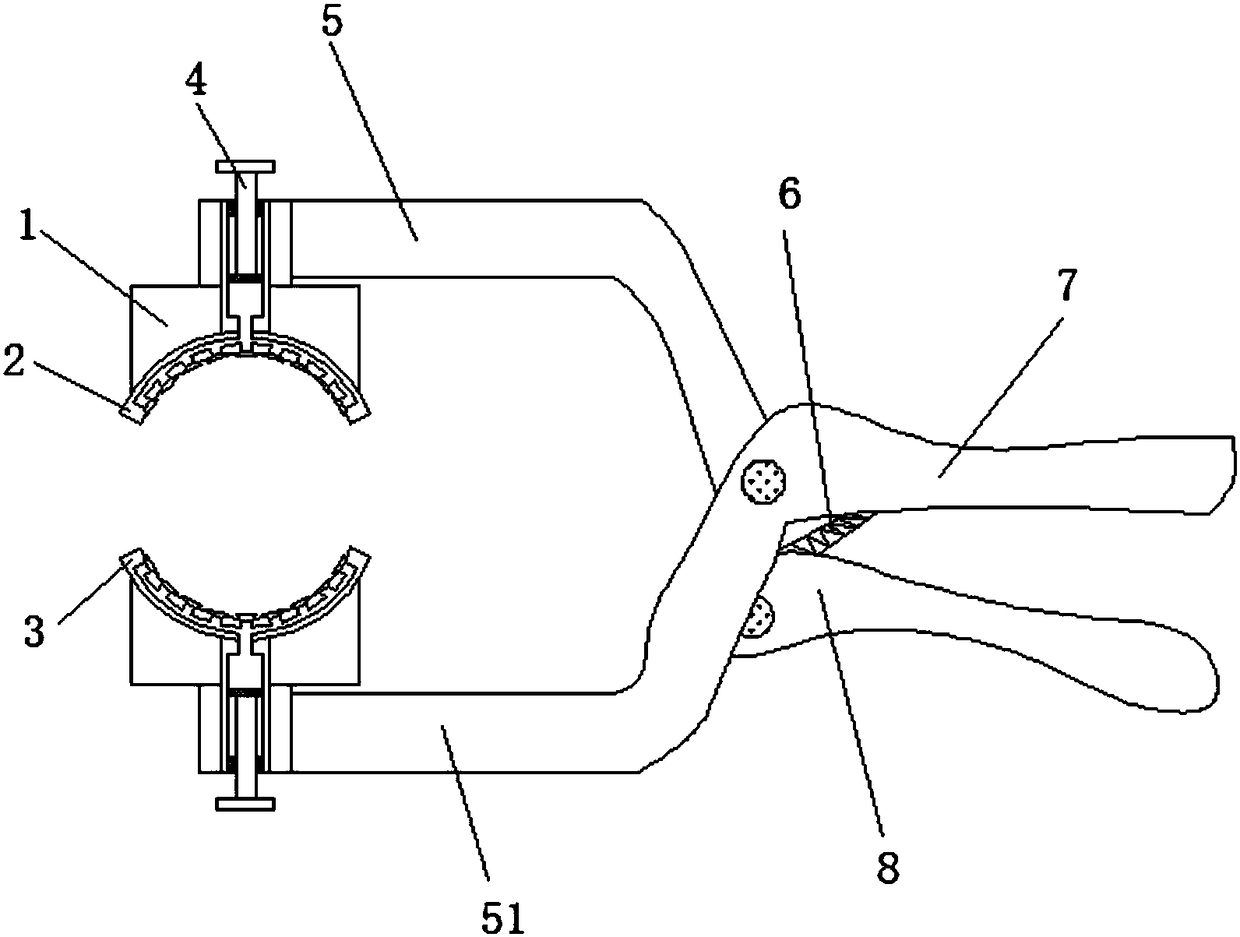

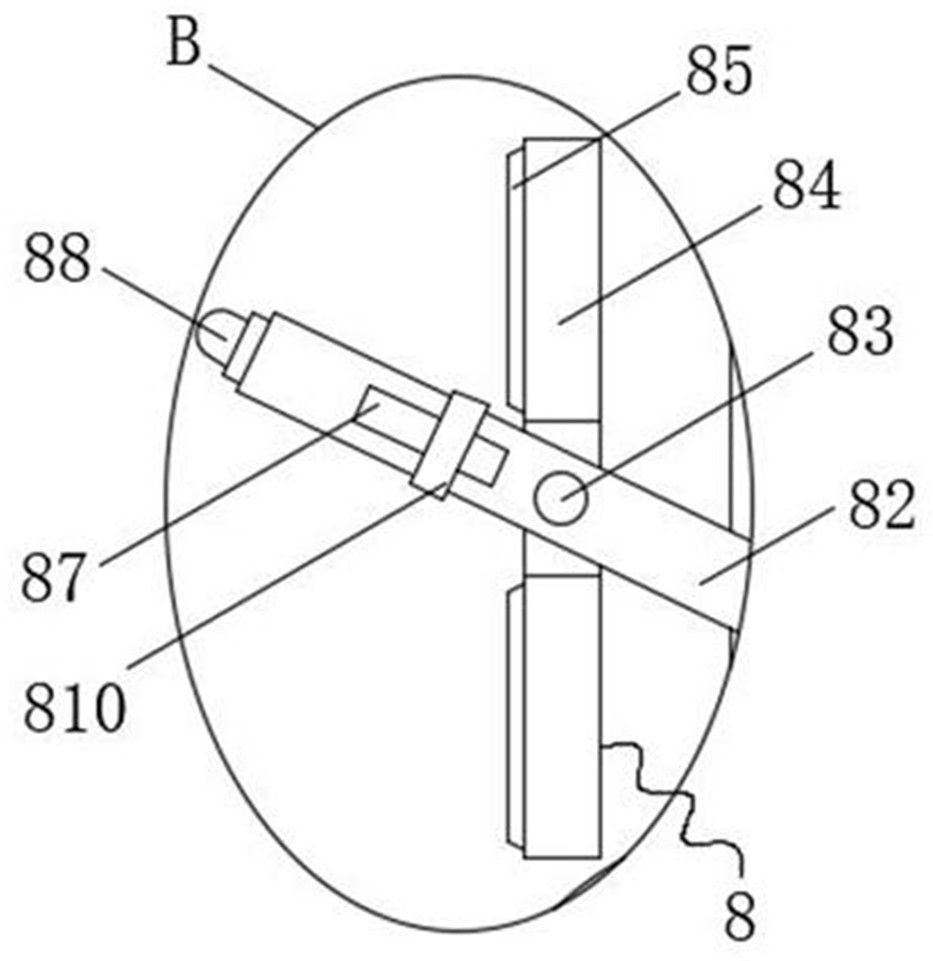

Antiskid welding clamp

InactiveCN108356477AFully fixedFixed effectWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringExtrusion

The invention discloses an antiskid welding clamp which comprises an upper connecting rod and a lower connecting rod. A fixing plate is welded to one side of the bottom of the upper connecting rod, and a first extrusion pad for fixing a circular pipe is arranged at the bottom of the fixing plate. A groove is formed in the part, on the top of the fixing plate, of the upper connecting rod, a spiralrotating rod is connected inside the groove in a threaded mode, a pushing rod is welded to the bottom of the spiral rotating rod, and the bottom of the groove communicates with a rubber pad at the bottom of the first extrusion pad through a communication pipe. In the antiskid welding clamp, the communication pipe is internally filled with hydraulic oil, the pushing rod can be driven to move downwards by rotating the spiral rotating rod, the hydraulic oil can be extruded to the rubber pad accordingly, then the rubber pad swells, accordingly the surface of the first extrusion pad is uneven, in this way, the circular pipe can be sufficiently fixed through the first extrusion pad, and the situation that the surface of a first extrusion pad skids to affect fixation of the circular pipe is prevented.

Owner:郑州宸通机械设备有限公司

Multifunctional fixing device for neurosurgery department

ActiveCN110292446AFixed effectImprove convenienceNursing bedsInstruments for stereotaxic surgeryNeurosurgeryEngineering

The invention belongs to the technical field of medical apparatuses and instruments, and particularly relates to a multifunctional fixing device for a neurosurgery department. The device comprises a fixing plate, and a head fixing device and a supporting device matched with the head fixing device are arranged on the fixing plate; the supporting device comprises a head supporting structure and a neck supporting structure matched with the head supporting structure; the head supporting structure comprises a head supporting plate and a head supporting transmission structure matched with the head supporting plate; the head fixing device comprises a first fixing gear rotationally connected with the fixing plate, and a multi-angle adjusting structure is connected to the first fixing gear; a supporting shell is arranged on the fixing plate, and the neck supporting structure comprises a neck supporting plate and a neck transmission structure matched with the neck supporting plate; the multi-angle adjusting structure can adjust the head fixing device according to the rotation angle of the head supporting plate, then, the head of a patient is fixed, meanwhile, the phenomenon that use is not convenient when the neck of a patient is not supported in use is avoided, and convenience and stability are improved.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

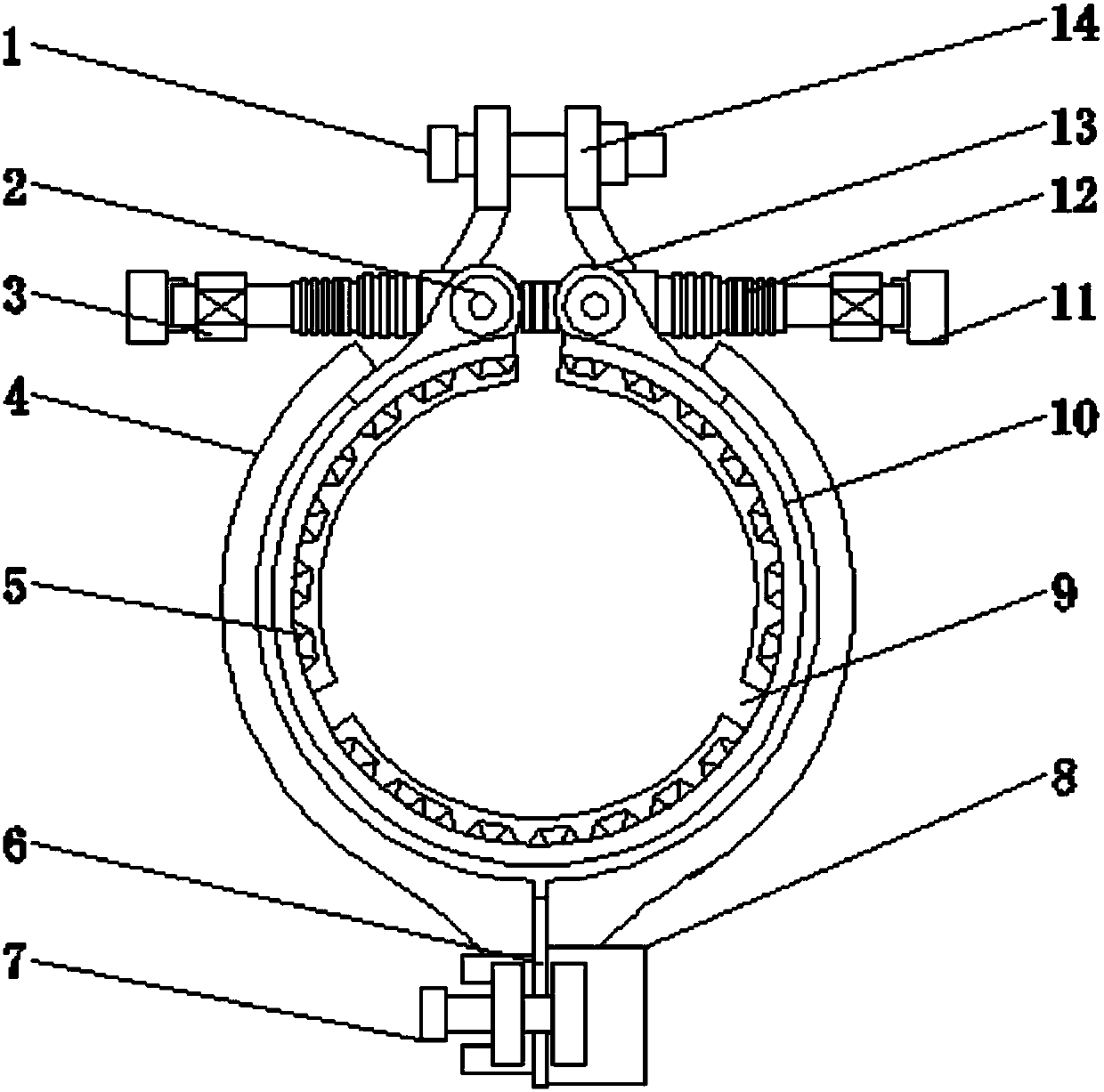

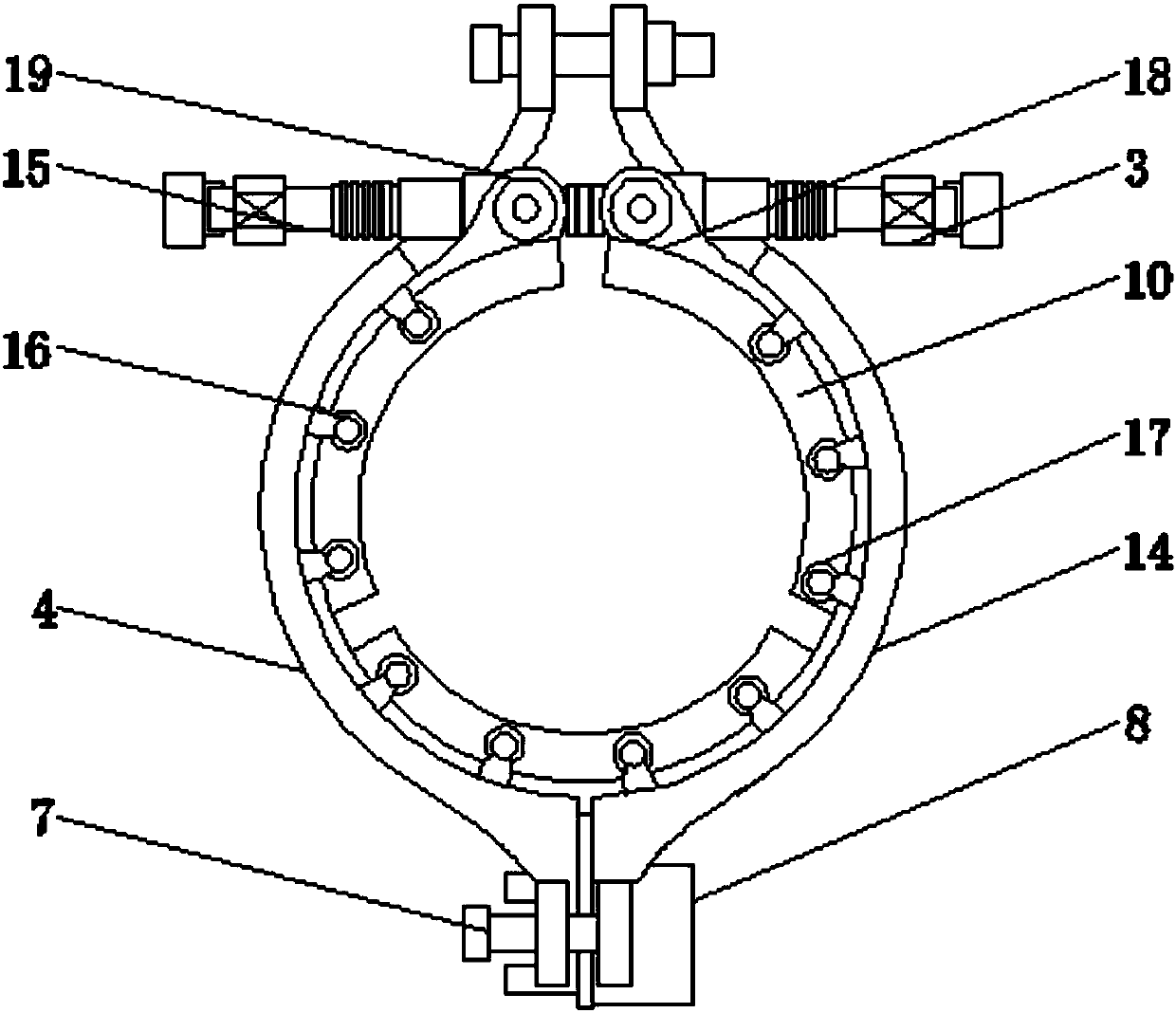

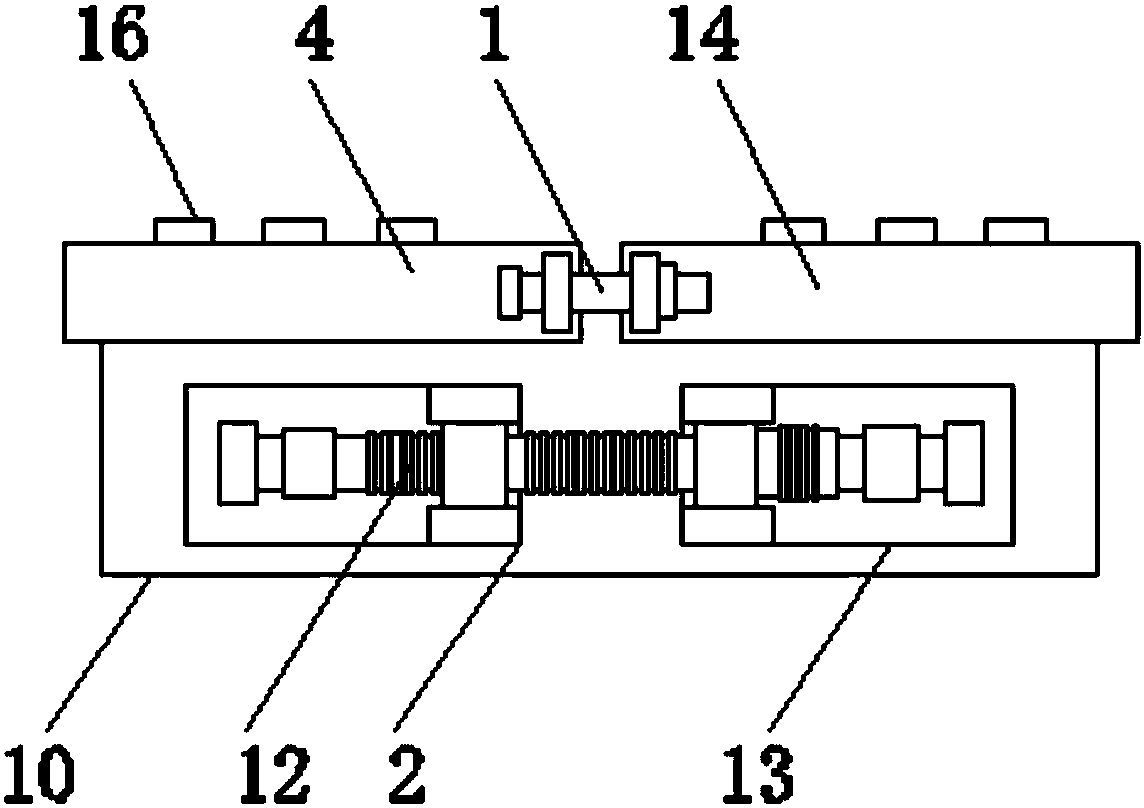

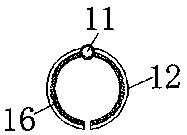

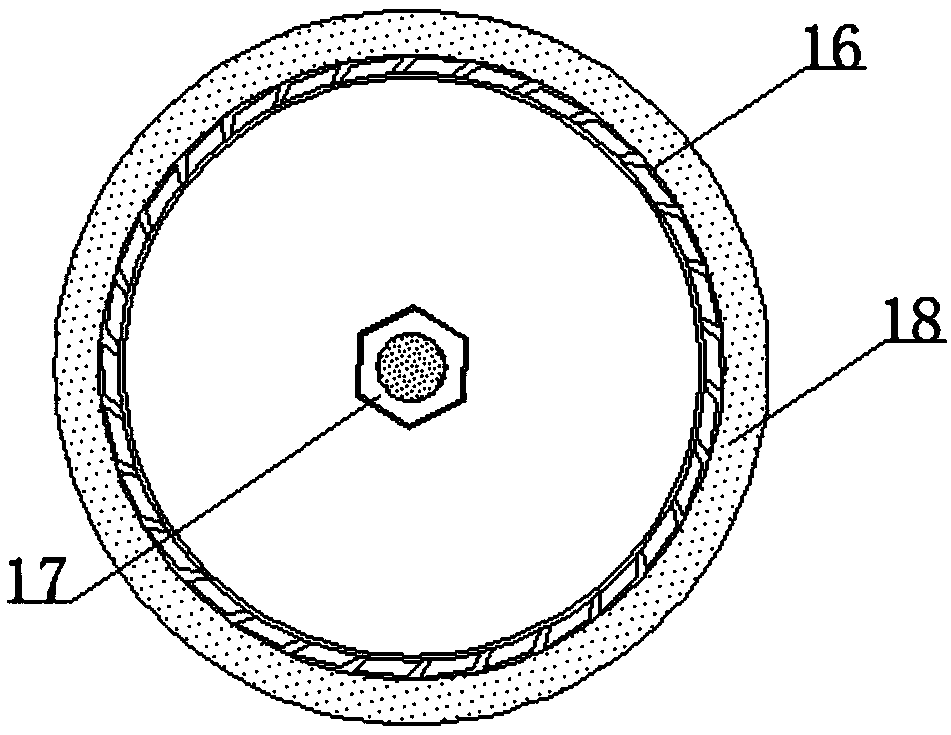

Intelligent locking hoop structure

InactiveCN109869382AWith stop back functionStable structureFriction grip releasable fasteningsSurface layerEngineering

The invention discloses an intelligent locking hoop structure. The structure comprises an elastic telescopic surface layer, a mounting part, an inner hoop and an adjusting rod, wherein a first hoop belt and a second hoop belt are wrapped around the outer side walls of the two sides of the inner hoop correspondingly, the bottom end of the inner hoop is provided with a mounting piece, the top of theinner hoop is provided with a first fastener and a second fastener correspondingly, and a second T-shaped rod sleeve and a first T-shaped rod sleeve are arranged at one end inside the first fastenerand one end inside the second fastener correspondingly. According to the structure, the first hoop belt, the second hoop belt, the mounting part, a locking bolt and a screw rod are installed, so thatwhen a hoop is used for clamping an article, matching of the first hoop belt and the second hoop belt is utilized, the force for clamping the article by the hoop is increased, and the problem that thearticle is prone to falling due to the fact that clamping of the hoop is unstable or clamping is not firm because the hoop is used for a long time is avoided.

Owner:天津市隆特科技发展有限公司

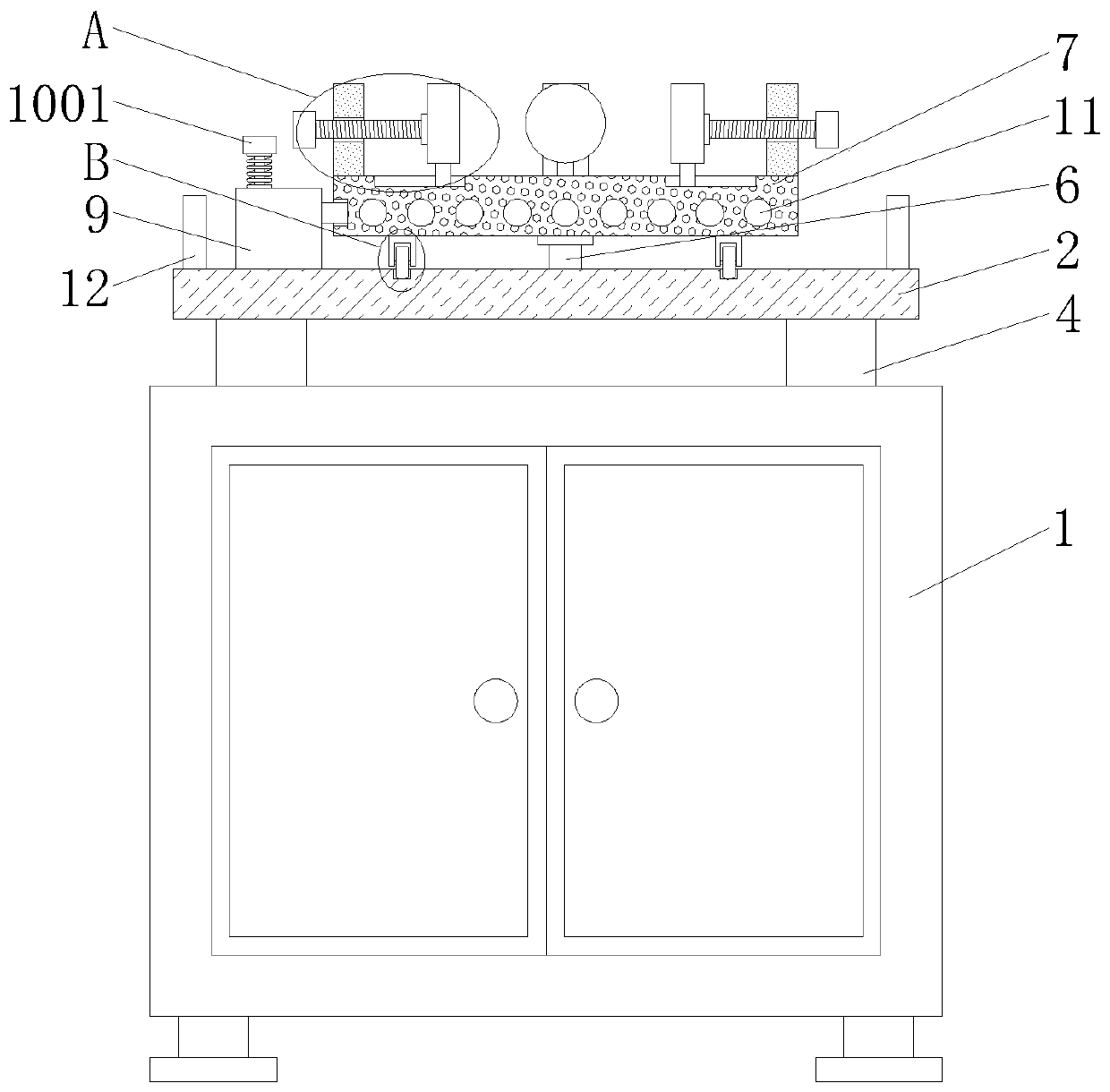

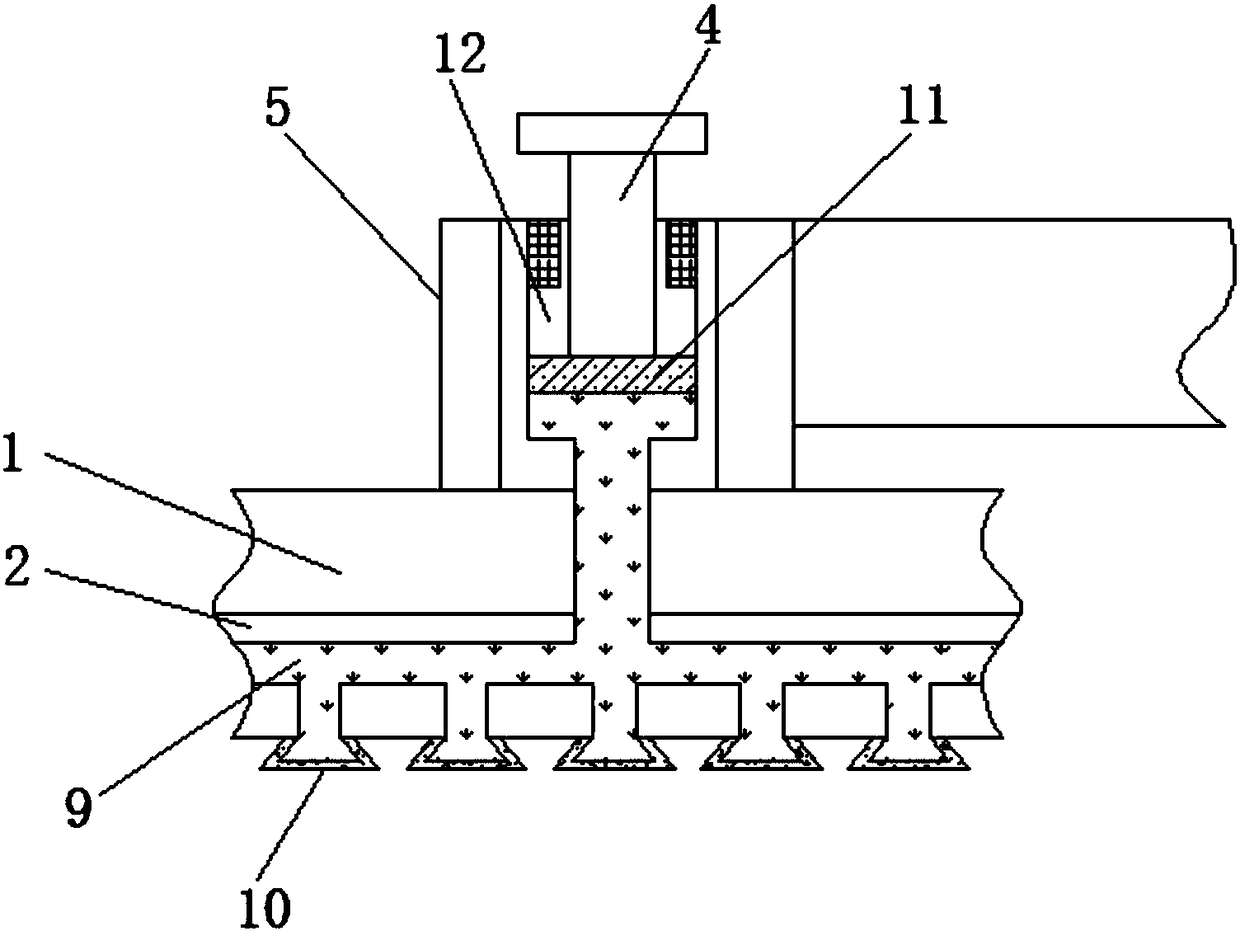

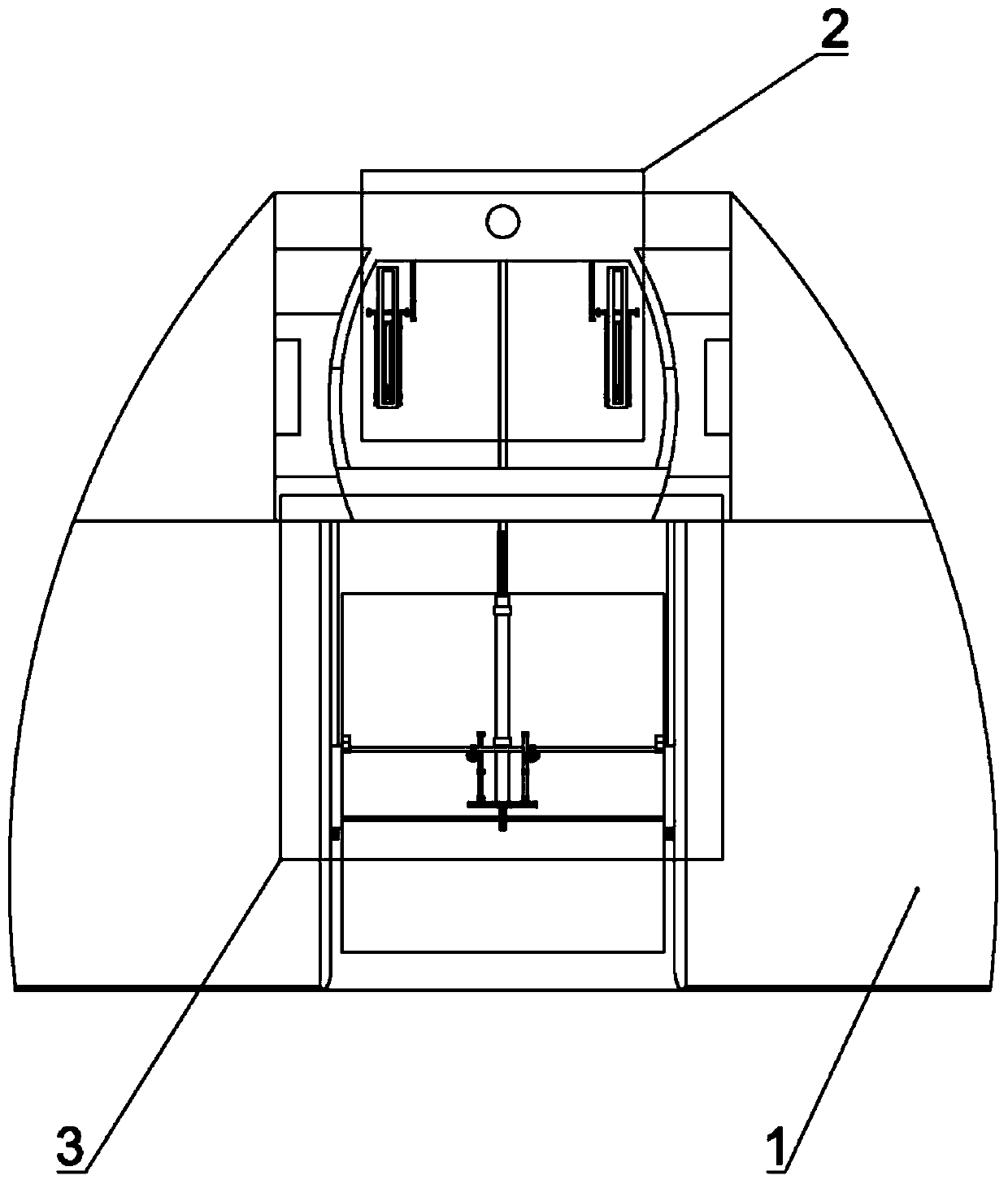

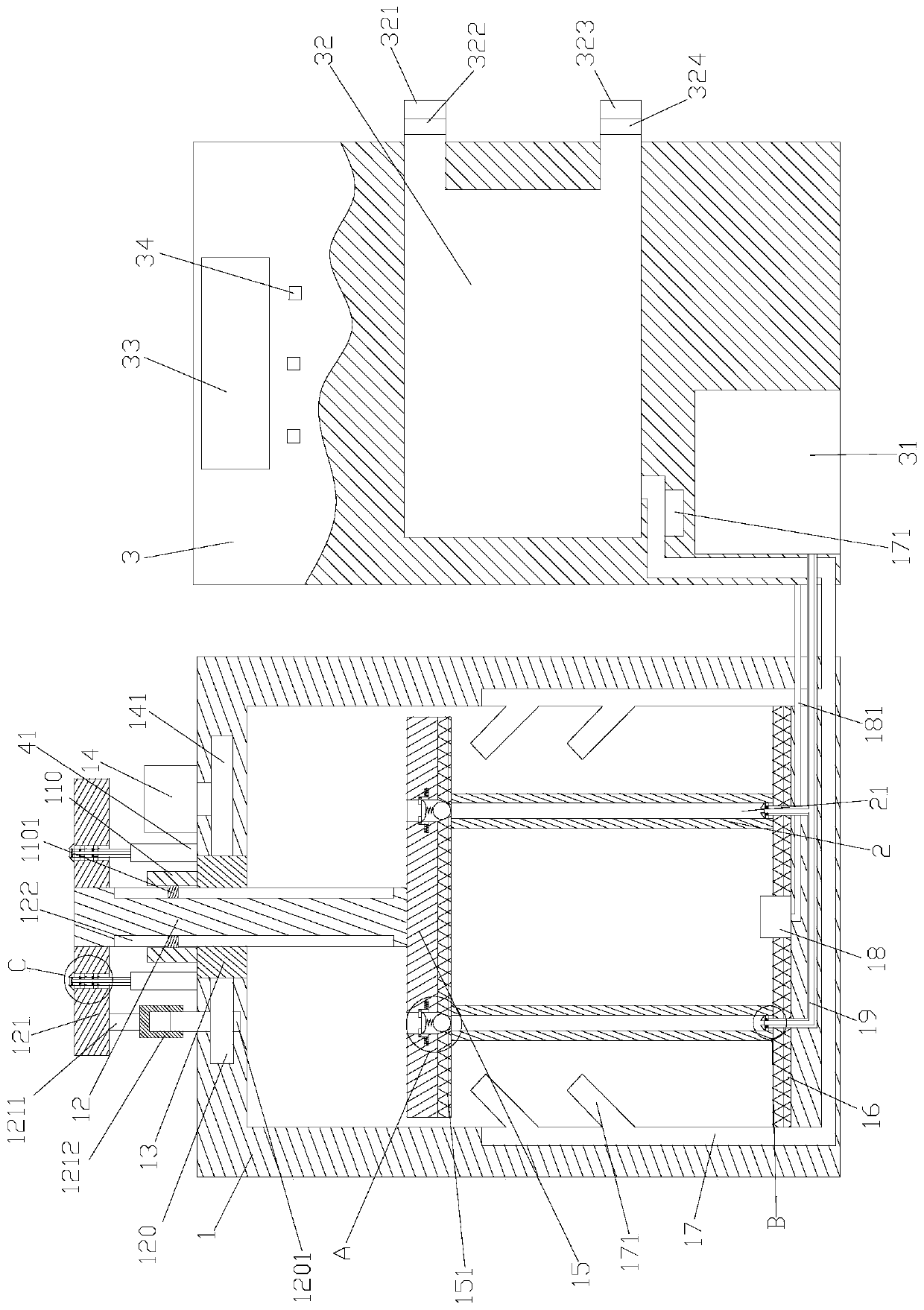

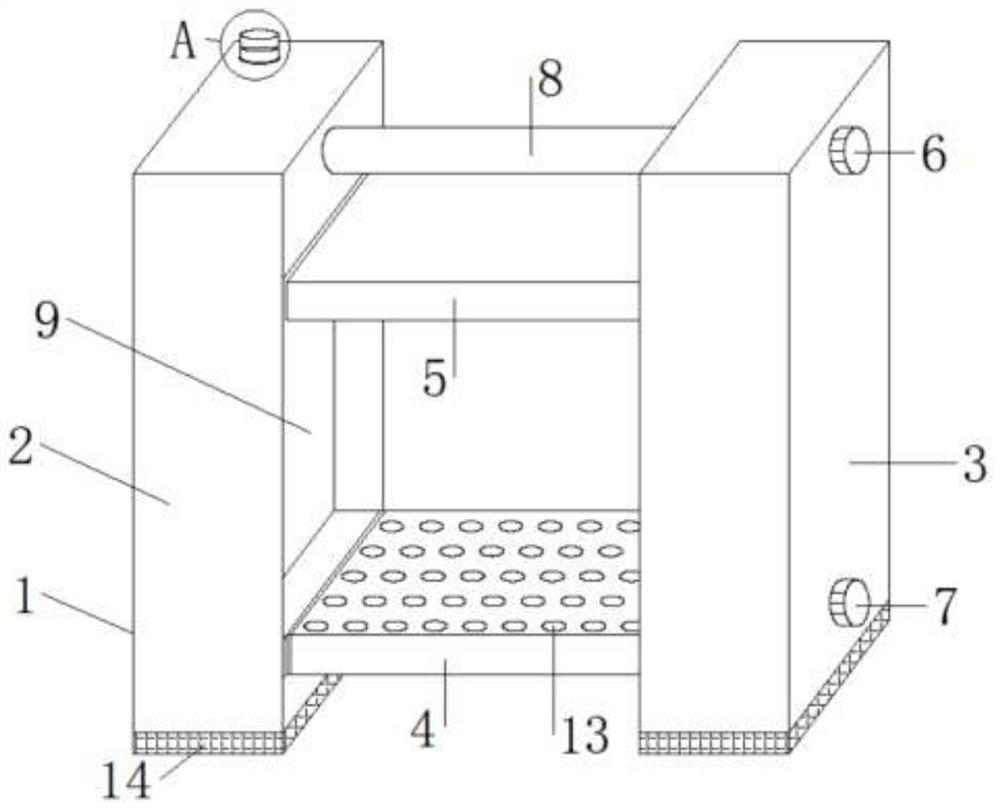

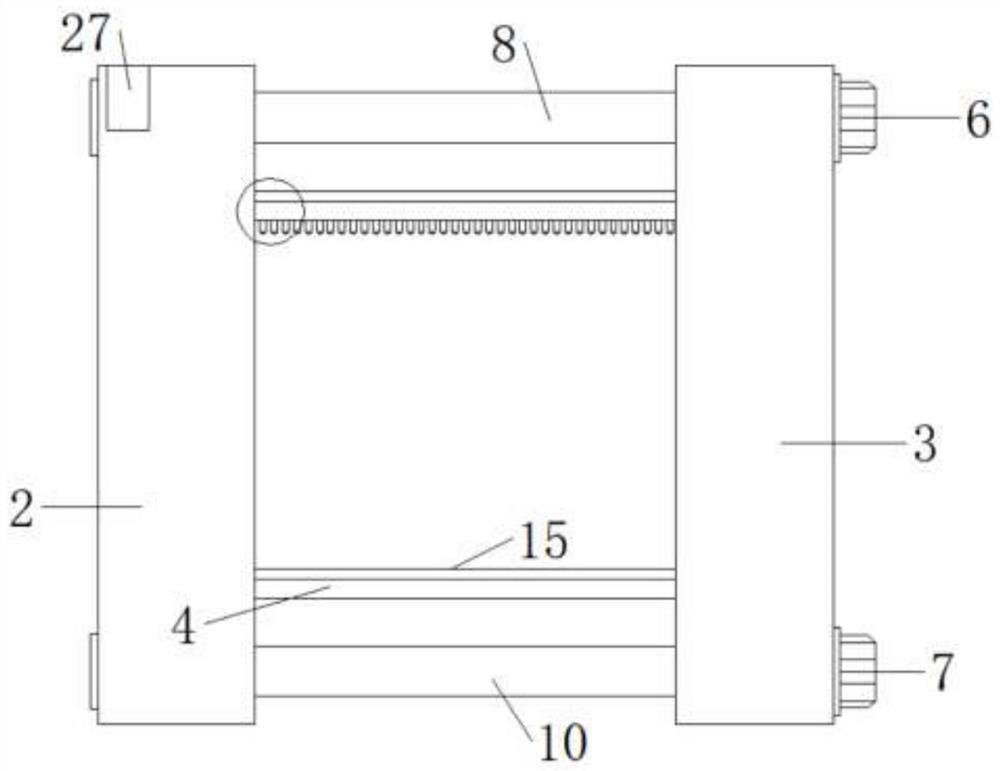

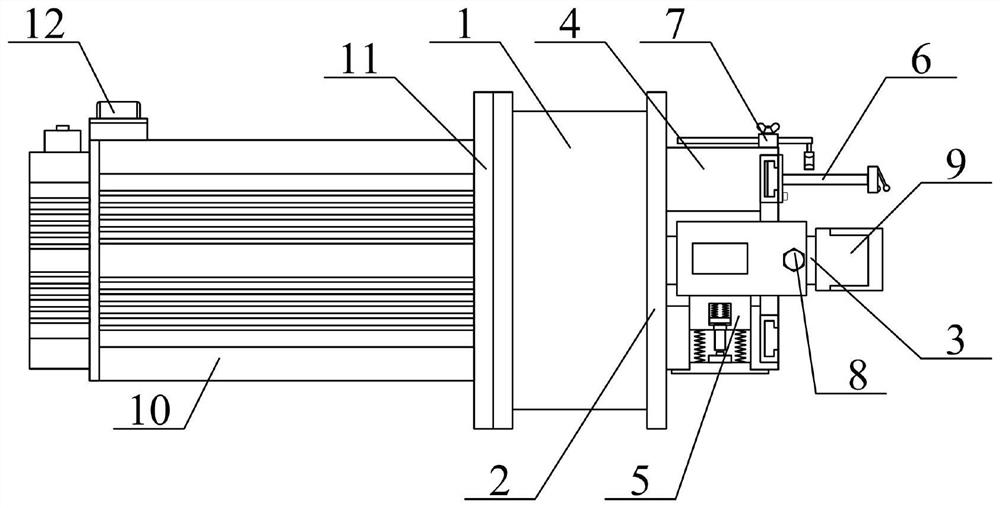

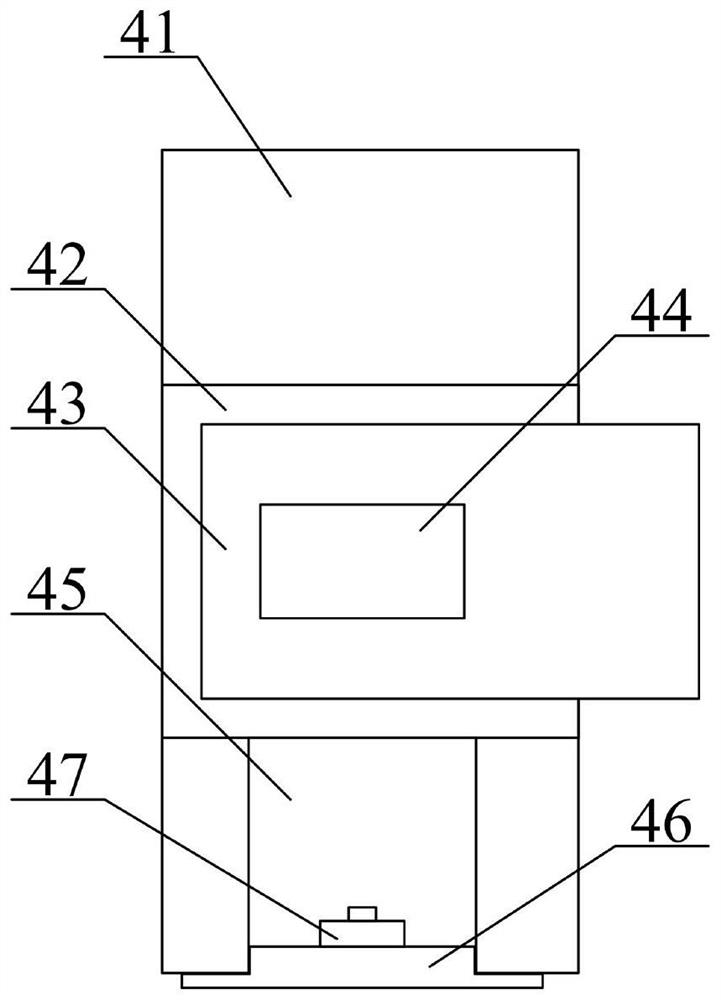

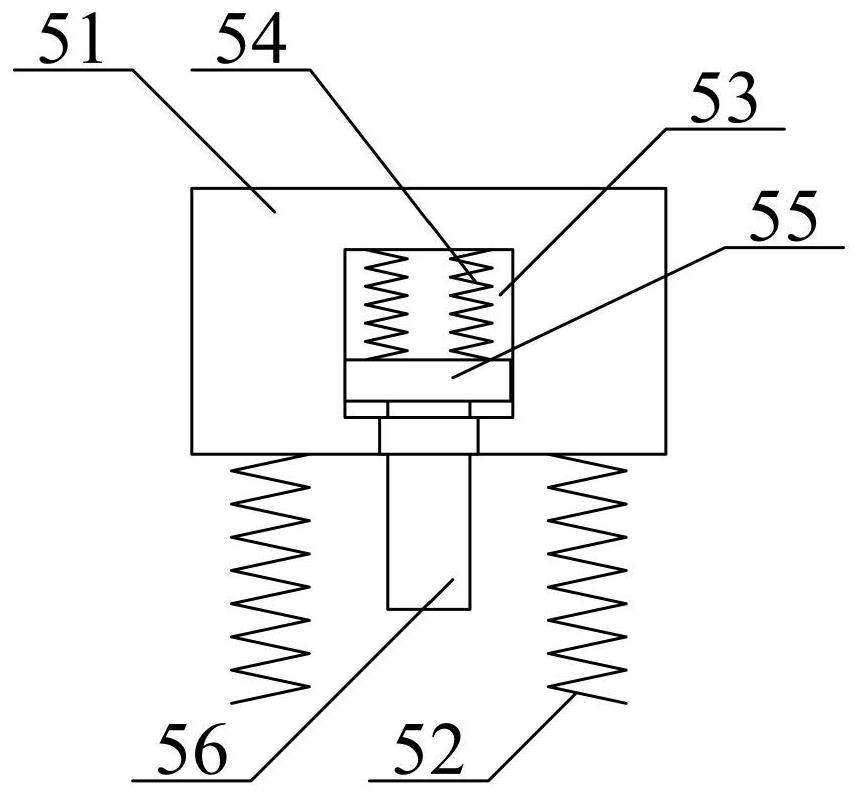

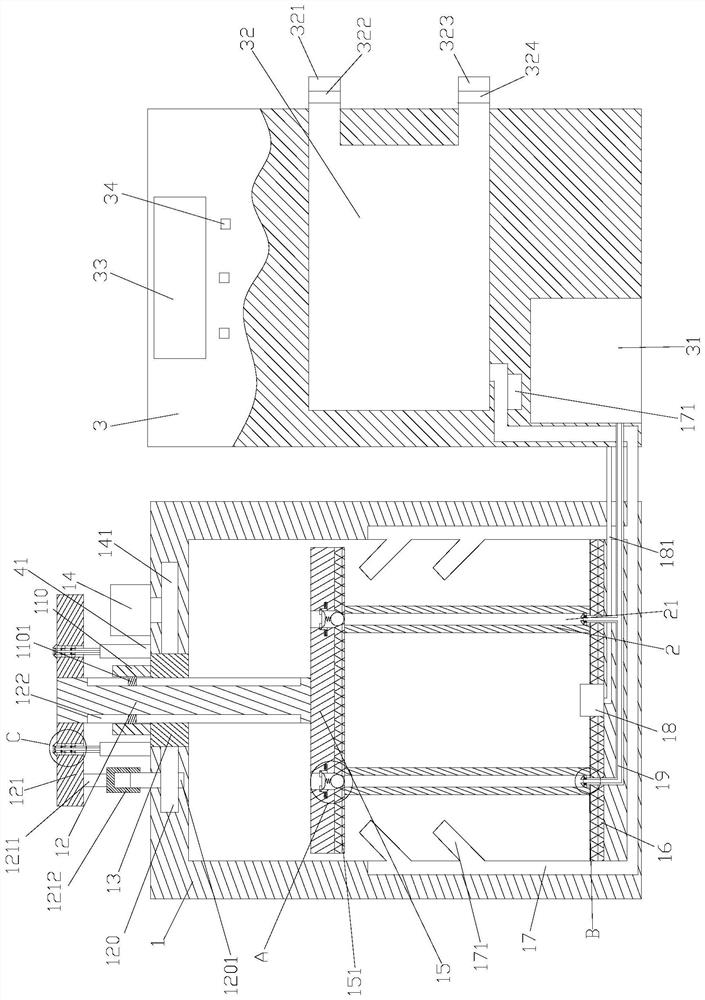

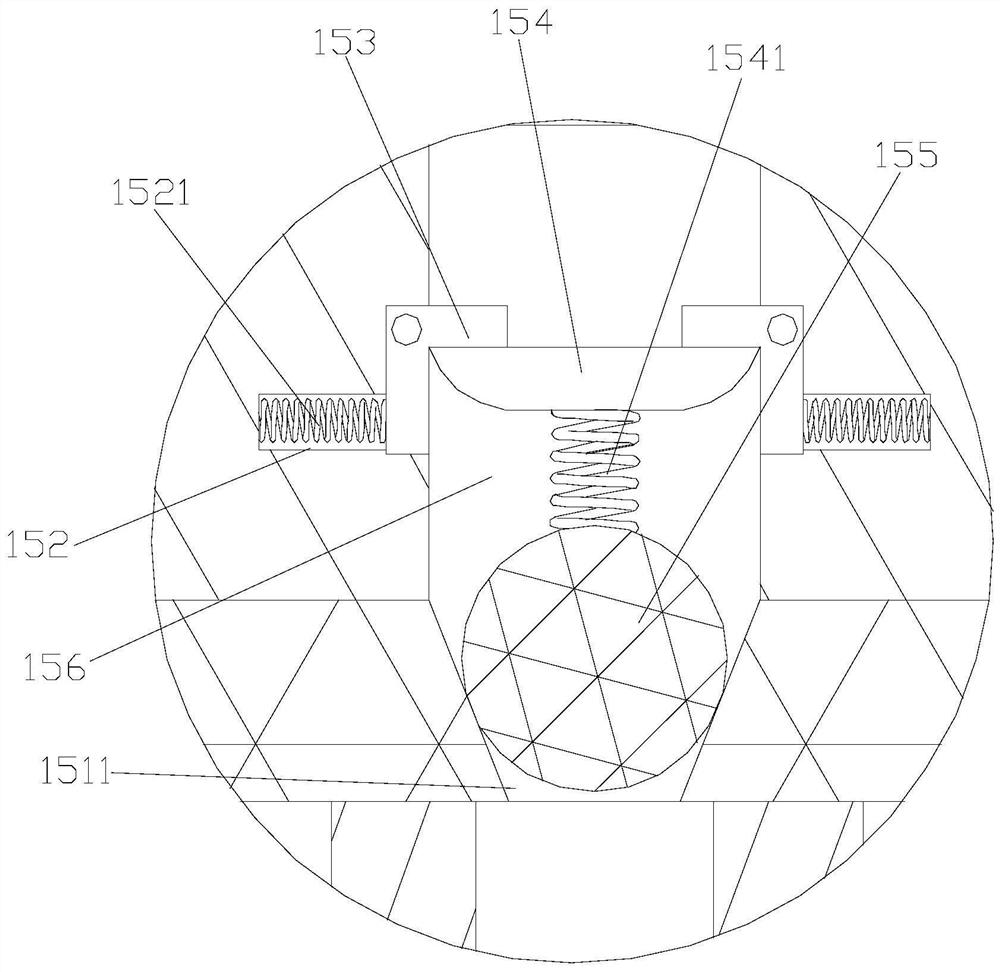

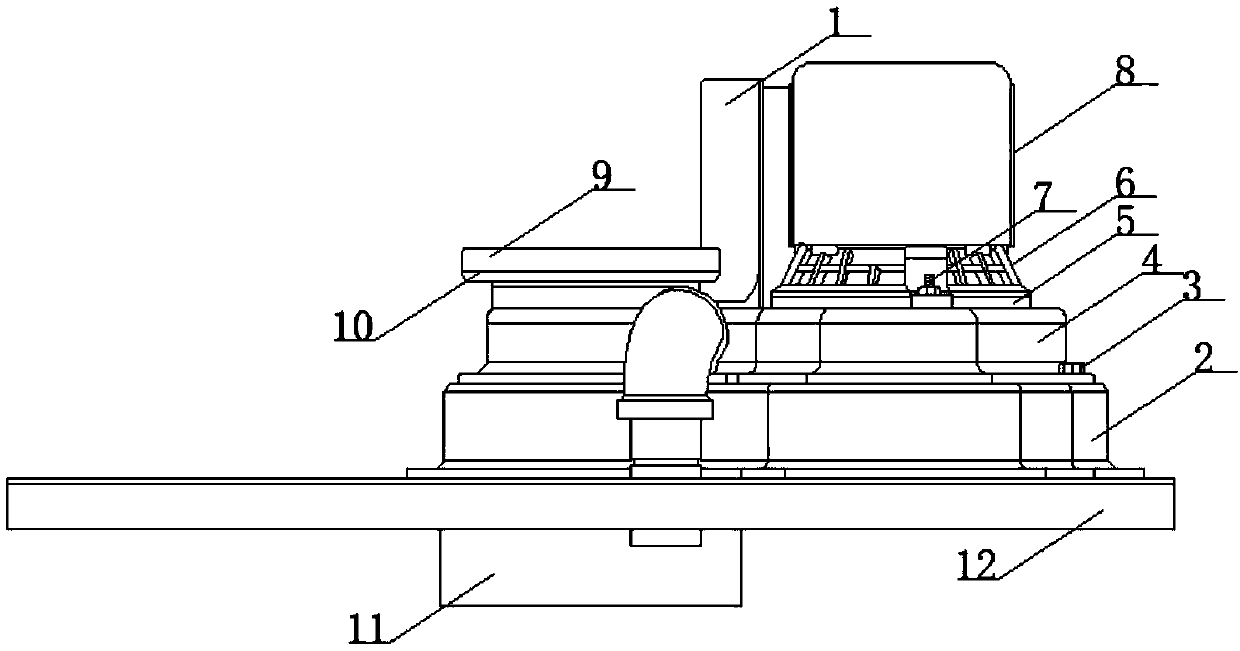

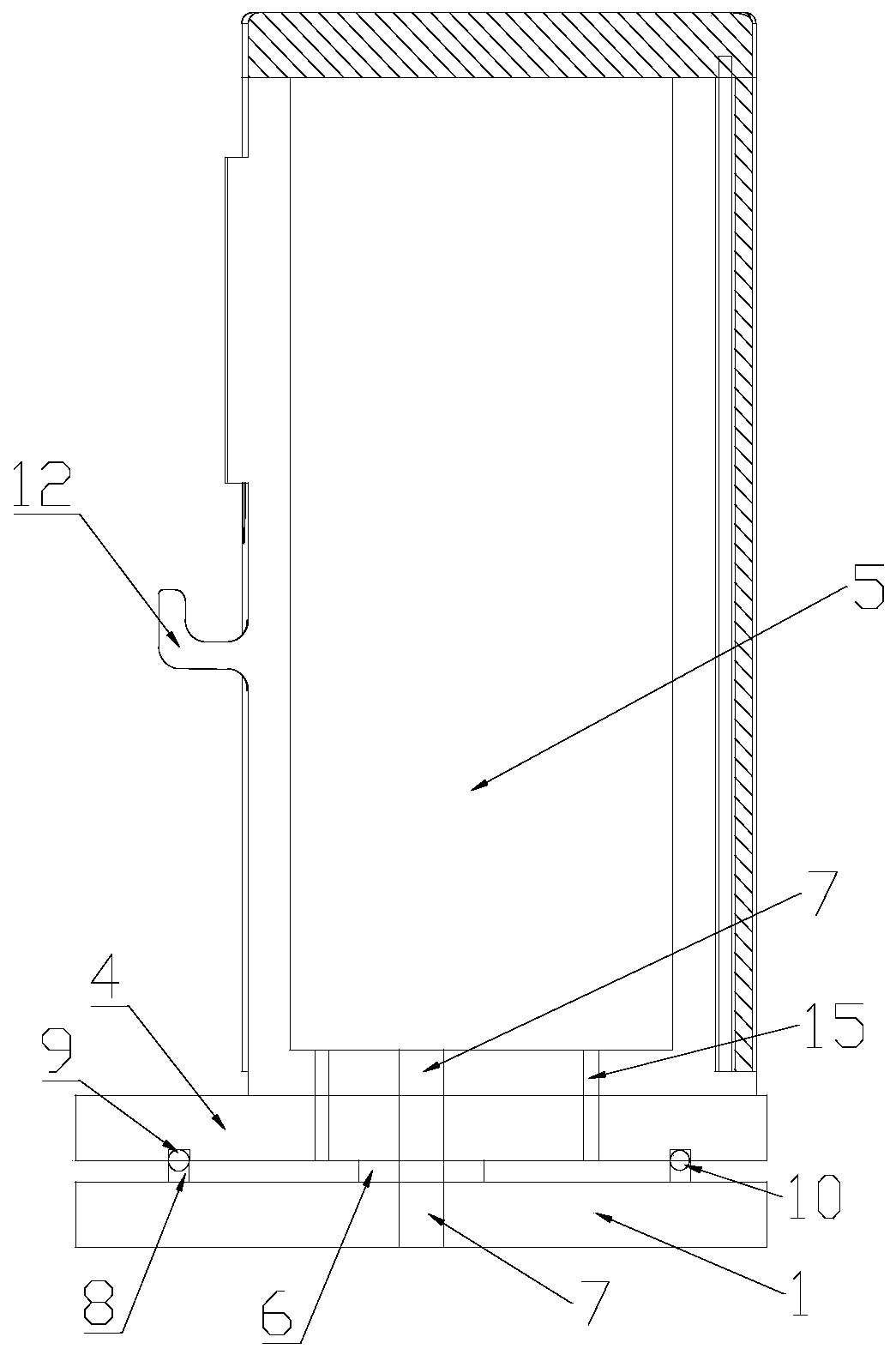

Water-cooled machine housing detection device with high stability

ActiveCN109916571AFixed effectEasy to fixDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringGas pressure transducer

The present invention discloses a water-cooled machine housing detection device with high stability. The device comprises a detection frame body and a control cabinet, the bottom portion of the detection frame body is provided with a seal pad, the top portion of the detection frame body is provided with a first fixed device, the inner wall of the detection frame body is provided with a water duct,the water duct is provided with a plurality of water injection nozzles; the first seal pad is provided with an air pressure sensor, and the air pressure sensor is connected with the control cabinet through a wire; the fixed device comprises a rotatable nut base arranged in the detection frame body, a screw rod penetrating the internal portion of the nut base and a pressing plate arranged at the bottom portion of the screw rod, the top portion of the screw rod is provided with a first spacing plate, the first spacing plate is provided with a through hole, the through hole is internally provided with a second fixed device, and the top portion of the detection frame body is provided with a spacing device; and the first fixed device is cooperated with the spacing device to prevent the nut base and the screw rod from jittering so as to improve the fixing effect of the first fixed module on the motor housing.

Owner:SHANDONG CHENXIN NEW ENERGY

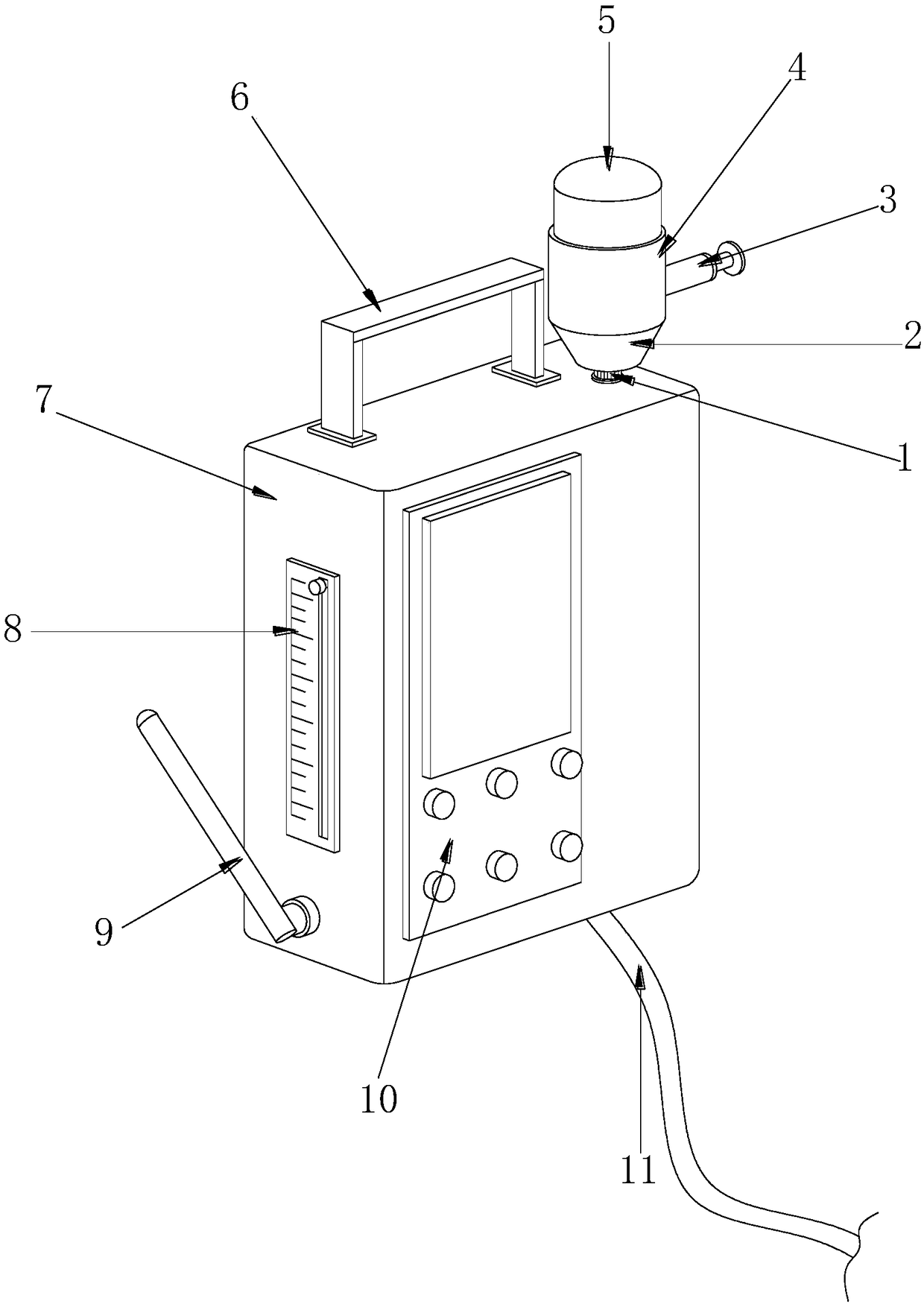

Remote infusion monitoring and alarming device of Internet of things

The invention discloses a remote infusion monitoring and alarming device of the Internet of things. The device structurally comprises a liquid outlet amount adjusting valve, an infusion bottle support, a vacuum pumping cylinder, a fixing rubber sleeve, an infusion bottle, a hanging frame, an infusion amount monitoring and remote alarming device, infusion millimeter adjusting buttons, an infusion millimeter scale, a signal receiving antenna, a controller and a liquid outlet hose. According to the infusion amount monitoring and remote alarming device, through the cooperation of an infusion liquid level monitoring mechanism and the infusion millimeter scale, the infusion amount required by a patient can be set; through a liquid level alarming mechanism, when the infusion amount set for the patient is reached, the signal receiving antenna can be used for transmitting a wireless signal to a control room for alarming; through an infusion mechanism, the infusion liquid can be evenly taken bythe patient, the probability of adverse reactions of the patient is reduced, the labor of medical staff is reduced, and the work efficiency is improved.

Owner:南京宇则智能科技有限公司

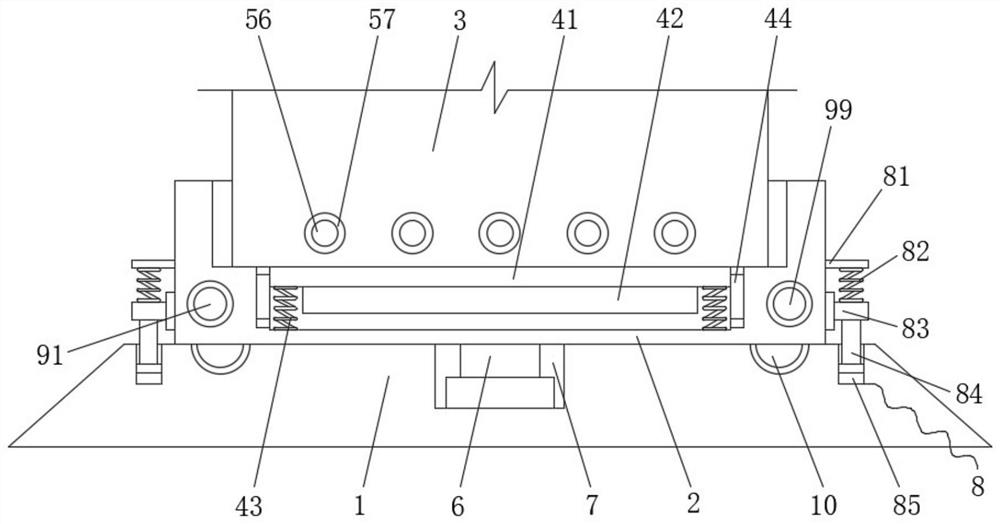

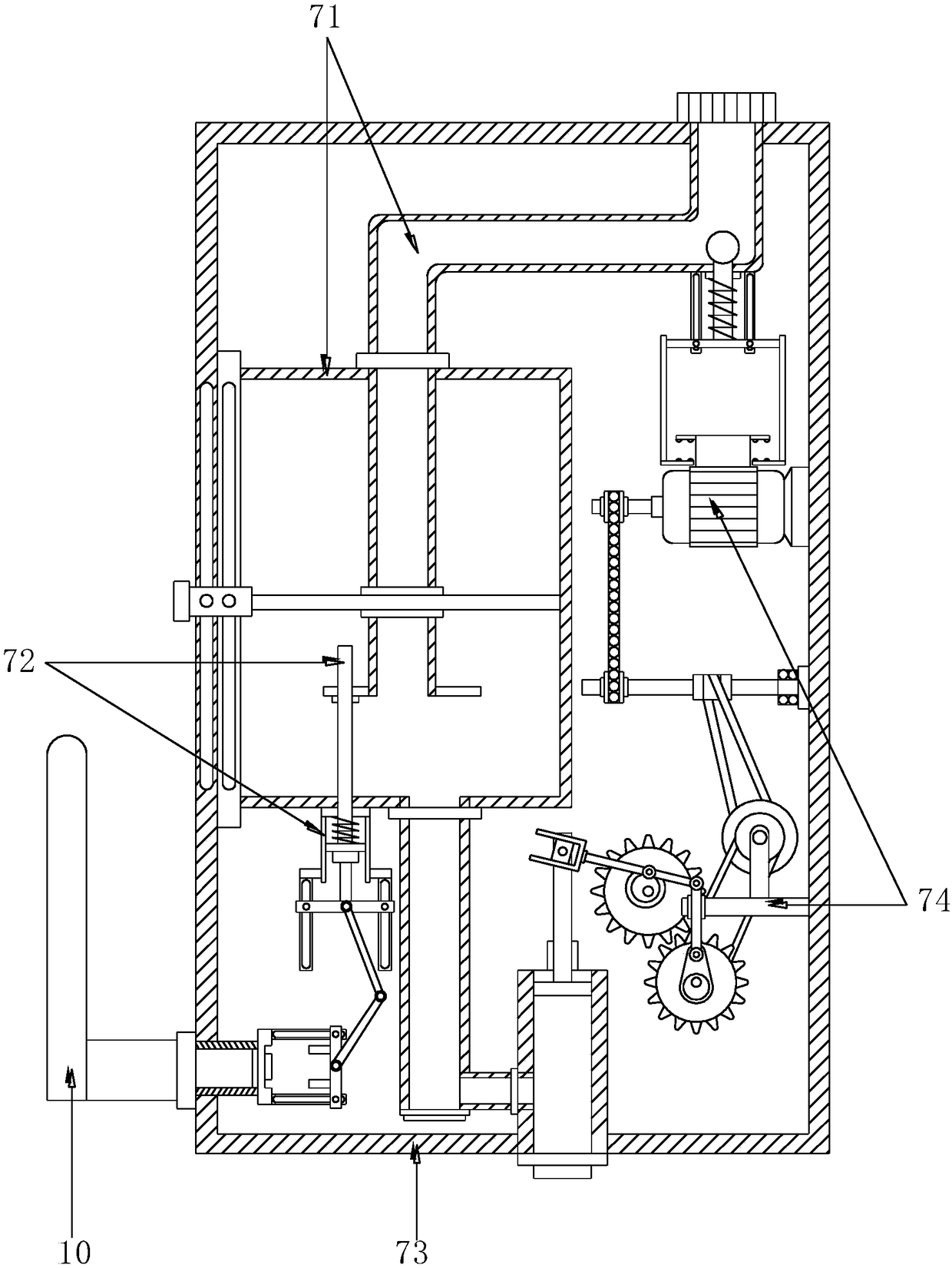

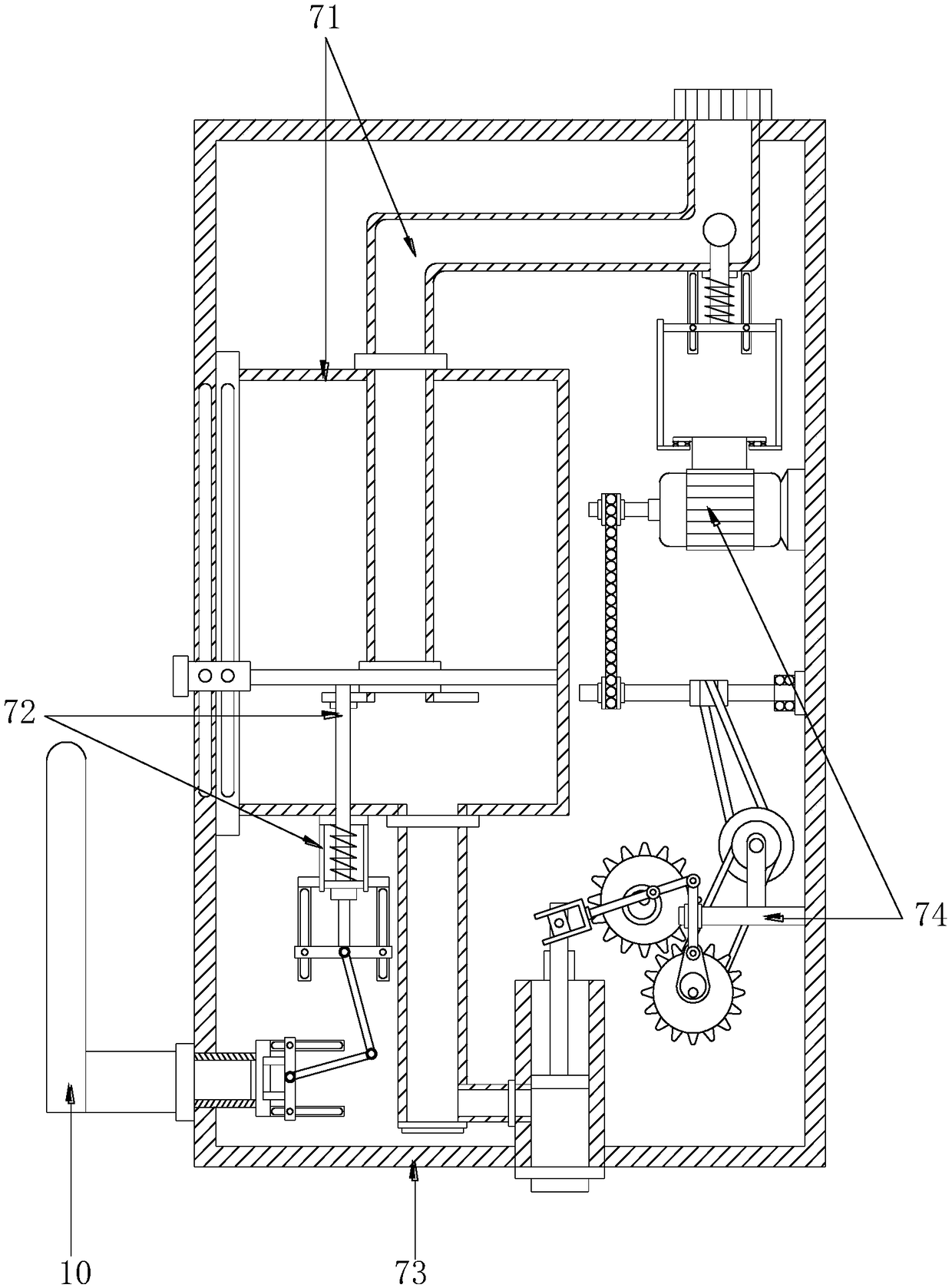

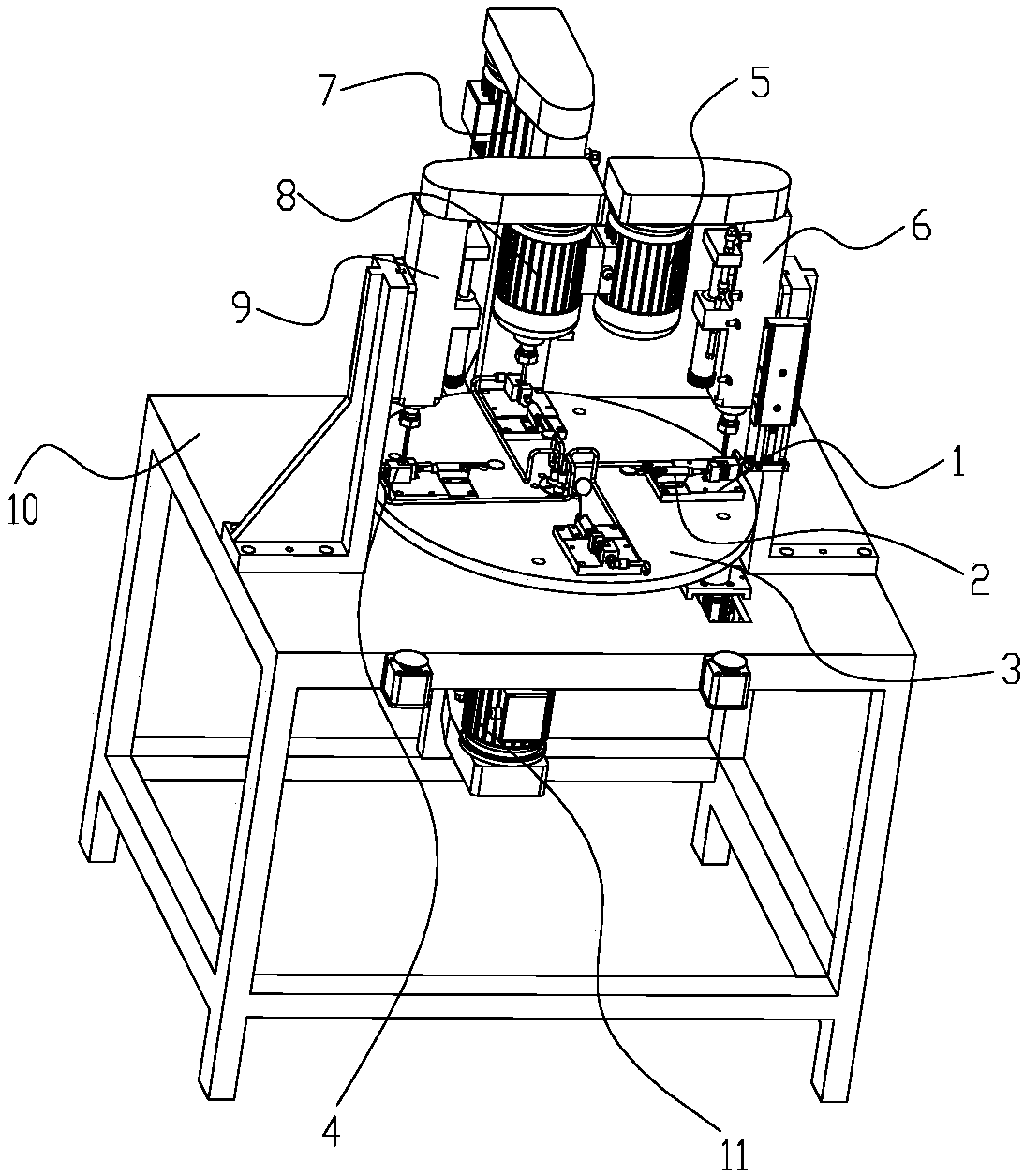

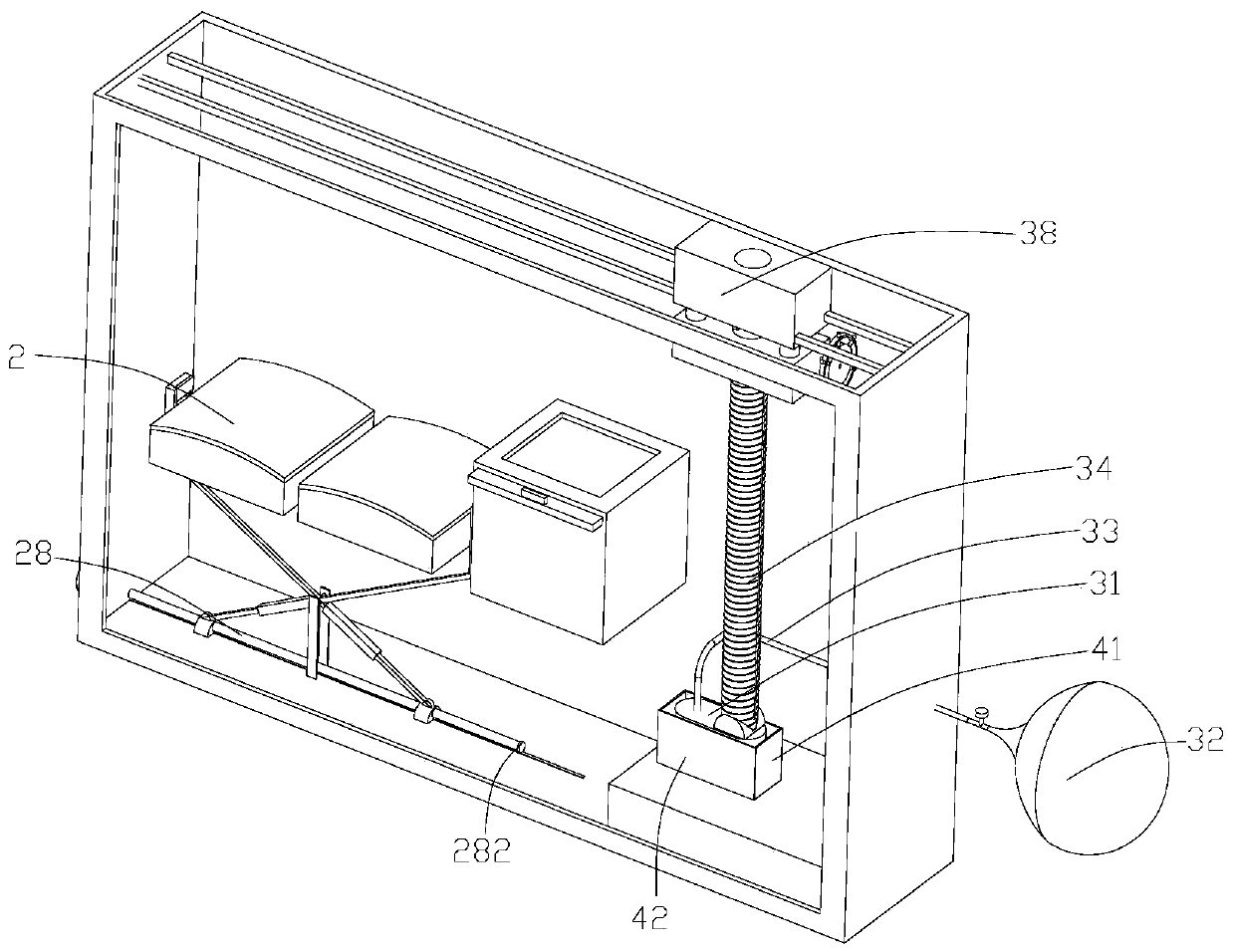

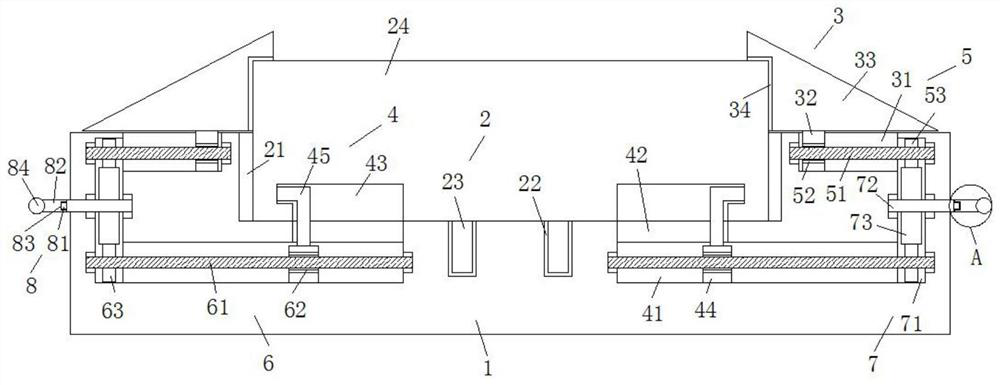

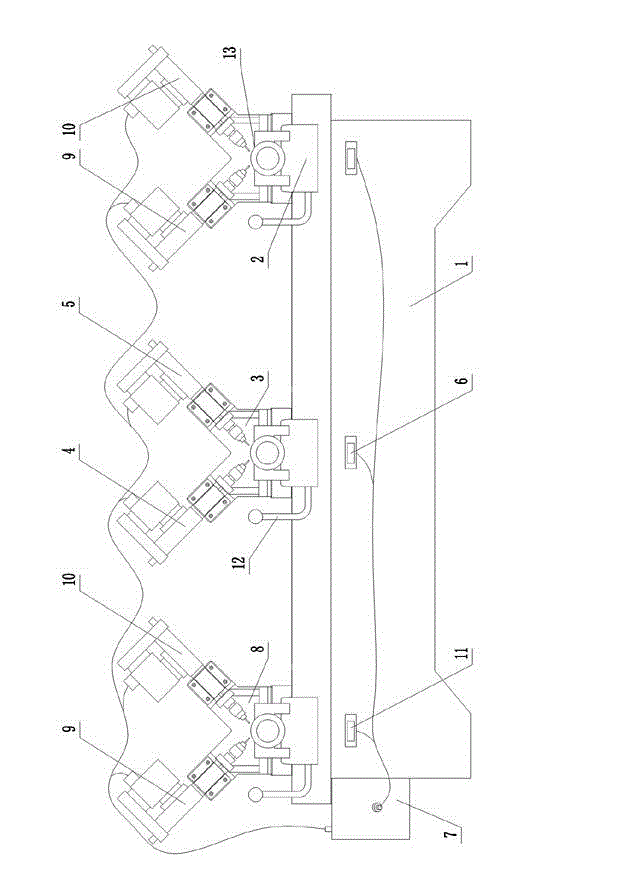

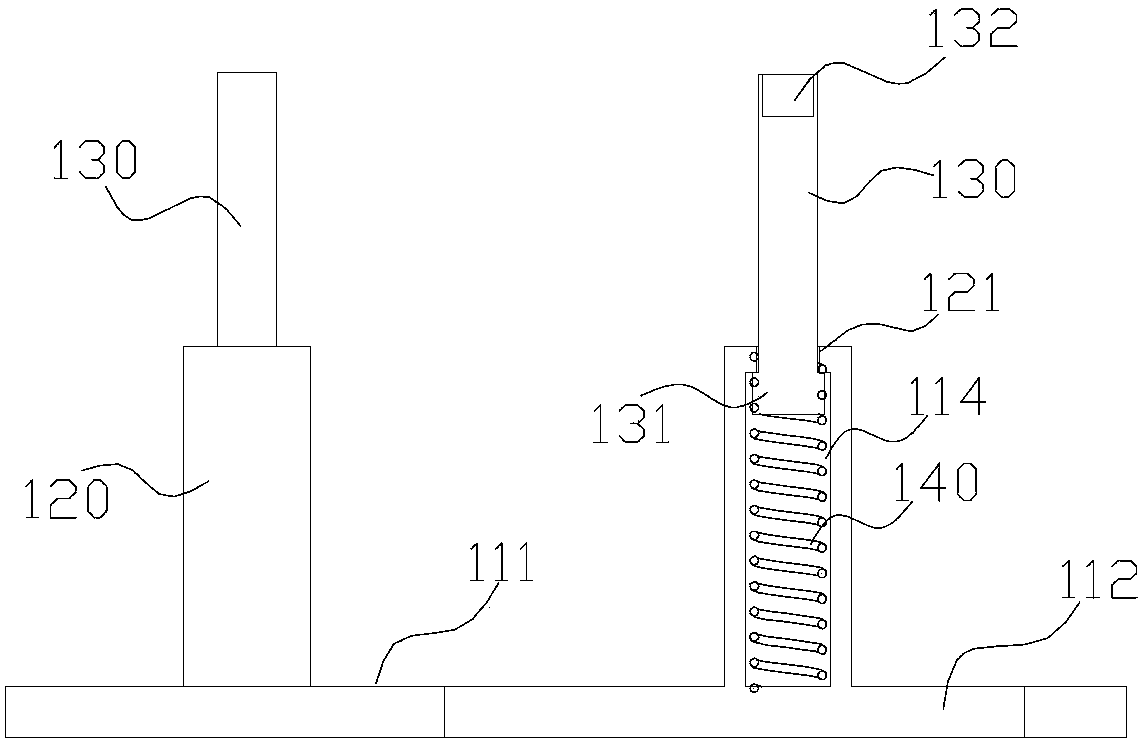

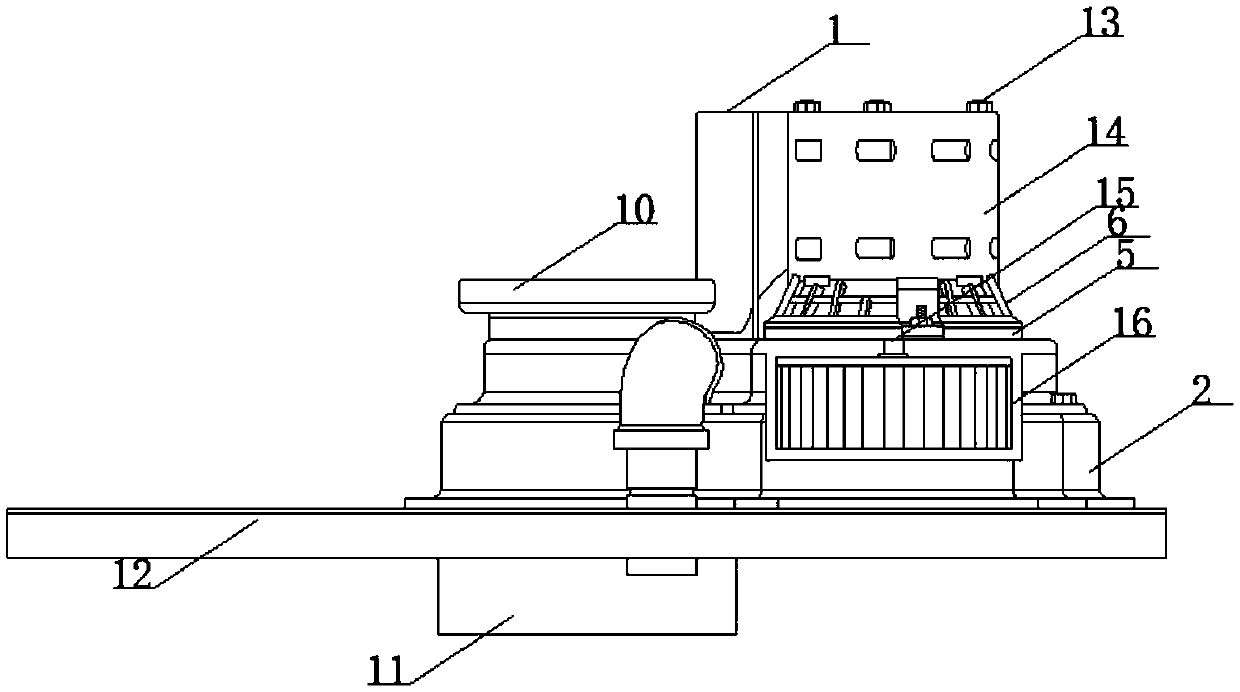

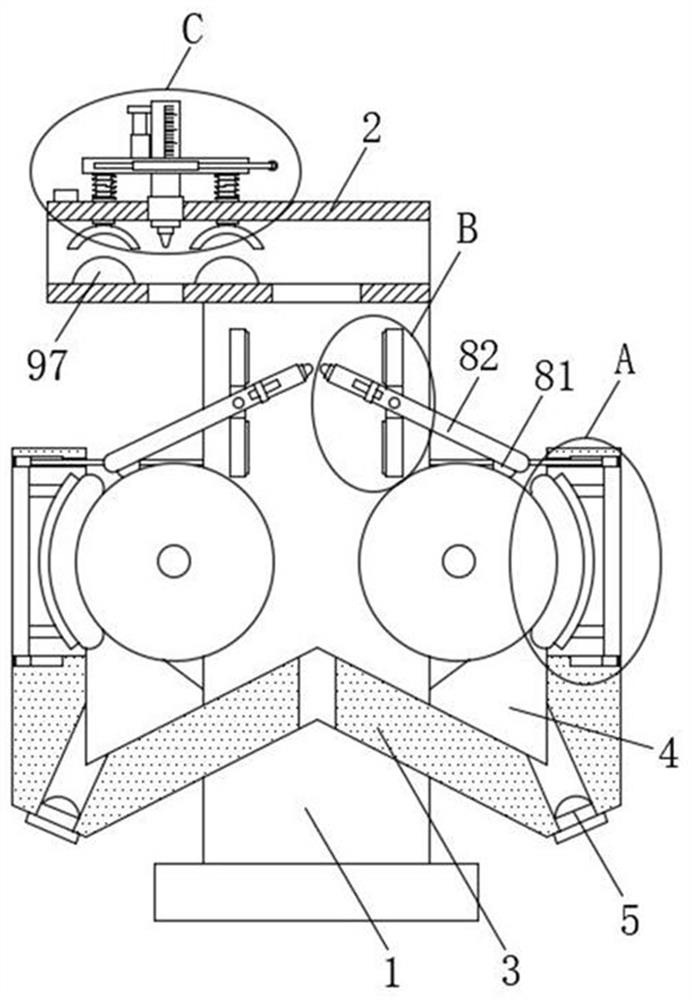

Machining equipment for wire harness fixing block

InactiveCN107553139AAchieve drilling effectRealize the effect of chamferingOther manufacturing equipments/toolsEngineeringMechanical engineering

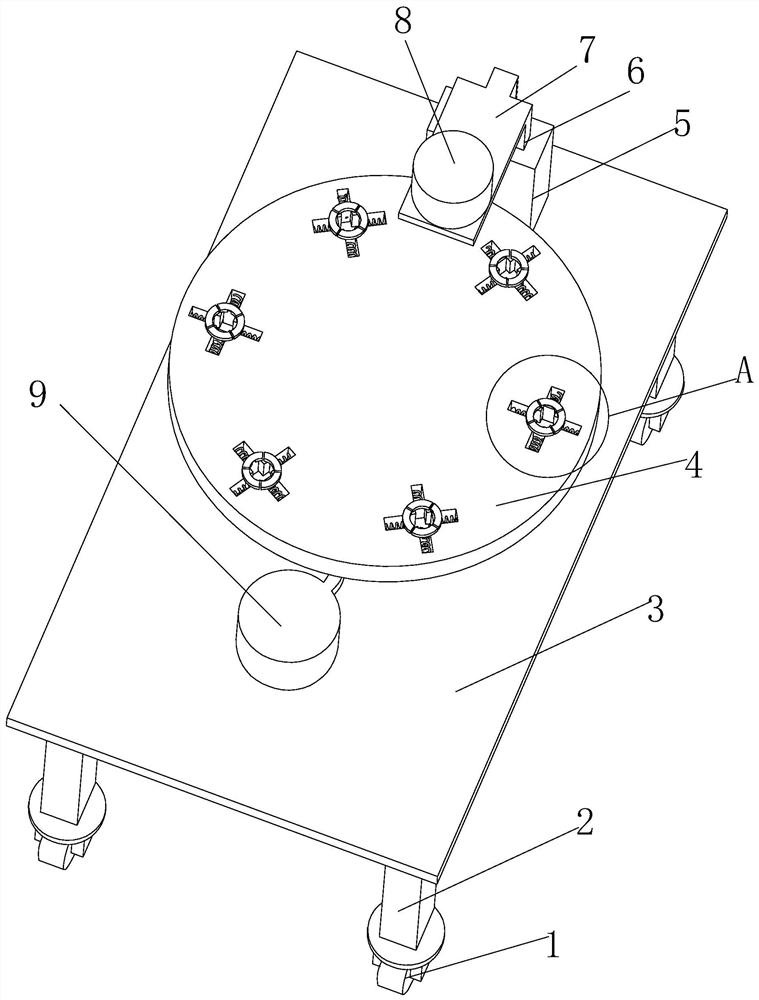

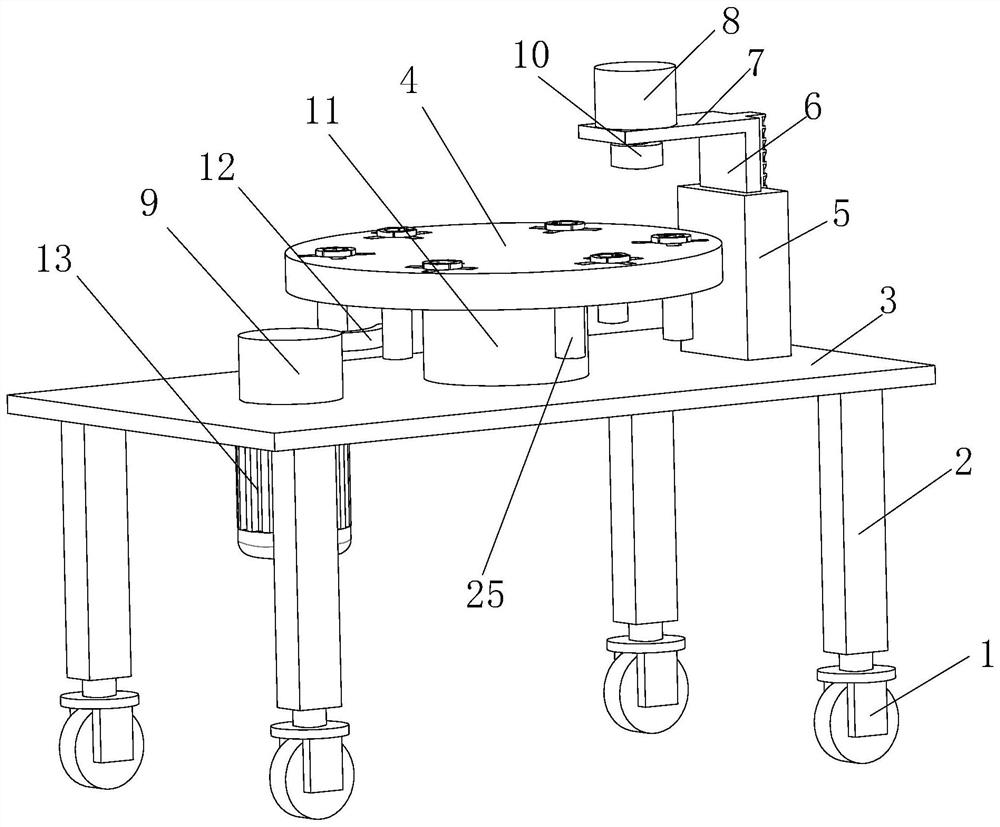

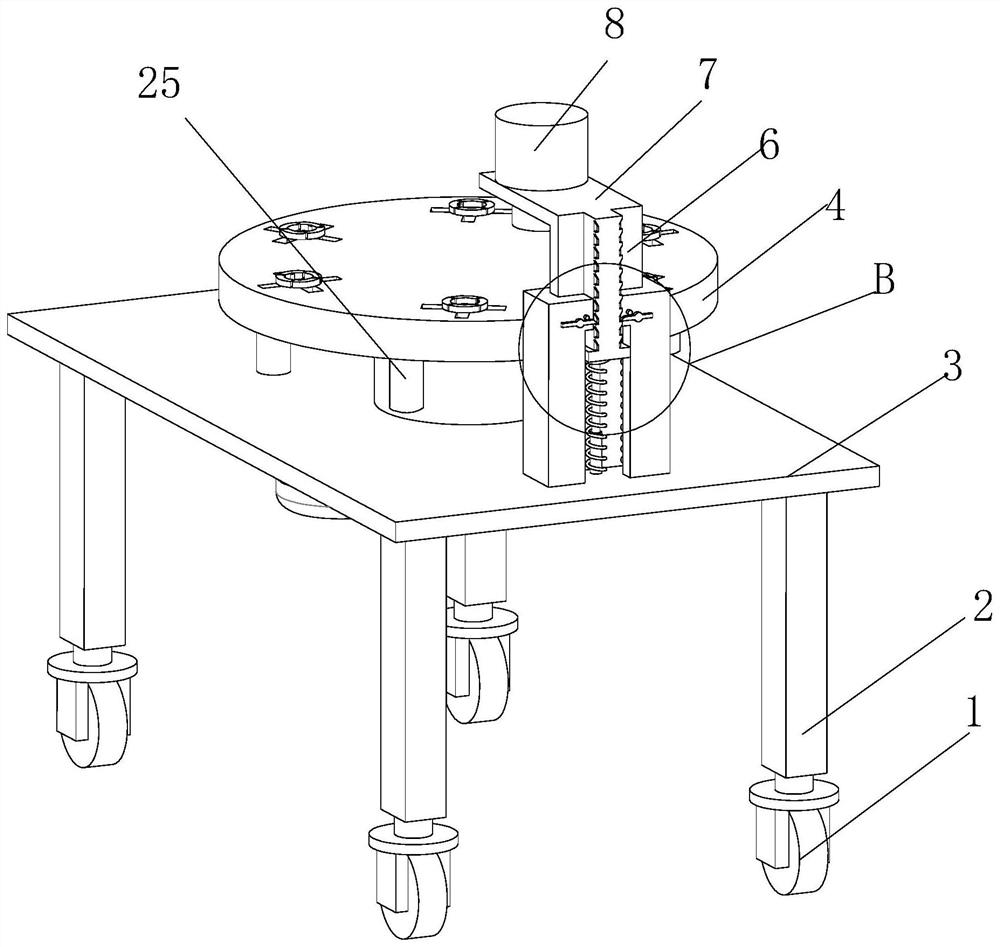

The invention provides machining equipment for a wire harness fixing block. The machining equipment comprises a work platform capable of rotating by itself, four stations, a drilling mechanism, a reaming mechanism and a first chamfering mechanism. The four stations are fixed to the work platform, the included angle between every two adjacent stations is 90 degrees, and a clamping mechanism used for clamping and fixing the wire harness fixing block is fixed to each station. The drilling mechanism is fixed to the position over the first station and used for drilling the wire harness fixing block. The reaming mechanism is fixed to the position over the second station and used for reaming the wire harness fixing block. The first chamfering mechanism is fixed to the position over the third station and used for chamfering the wire harness fixing block. The equipment is simple in structure and low in cost.

Owner:JIANGYIN JIANGSHI AUTO PARTS

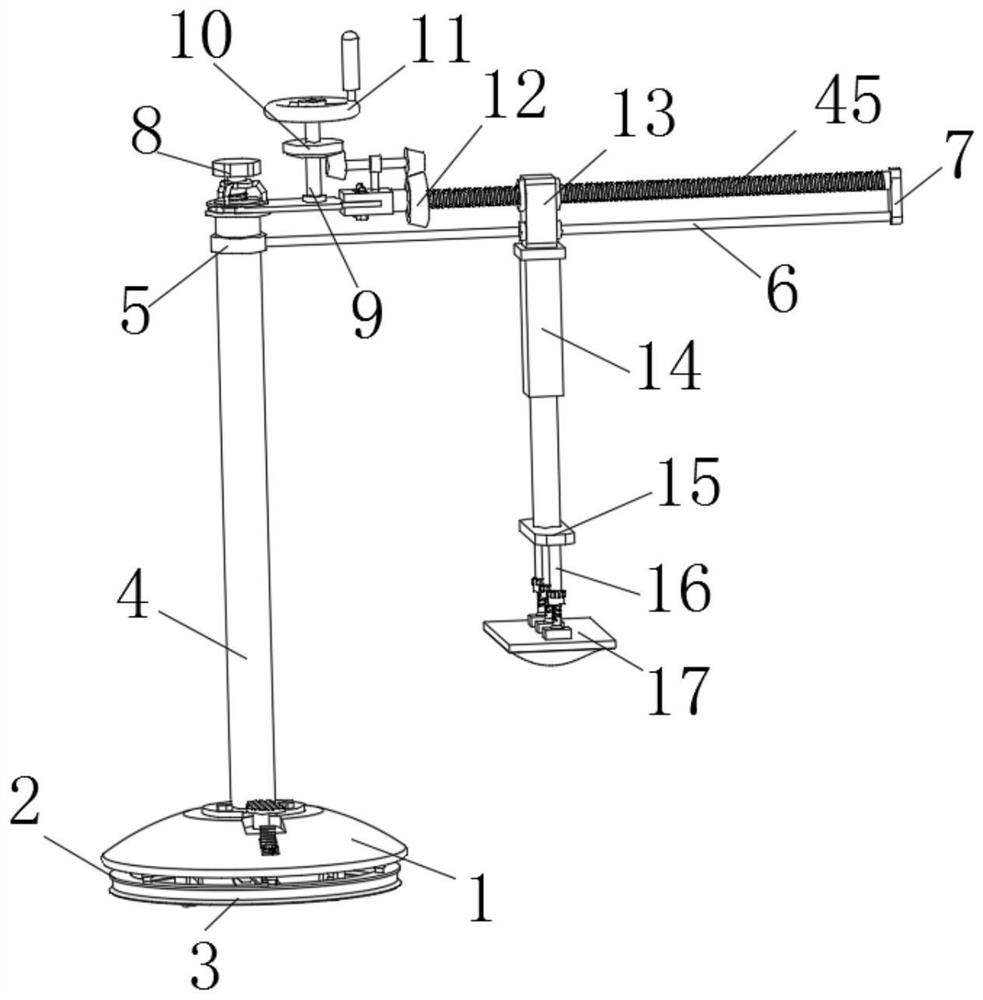

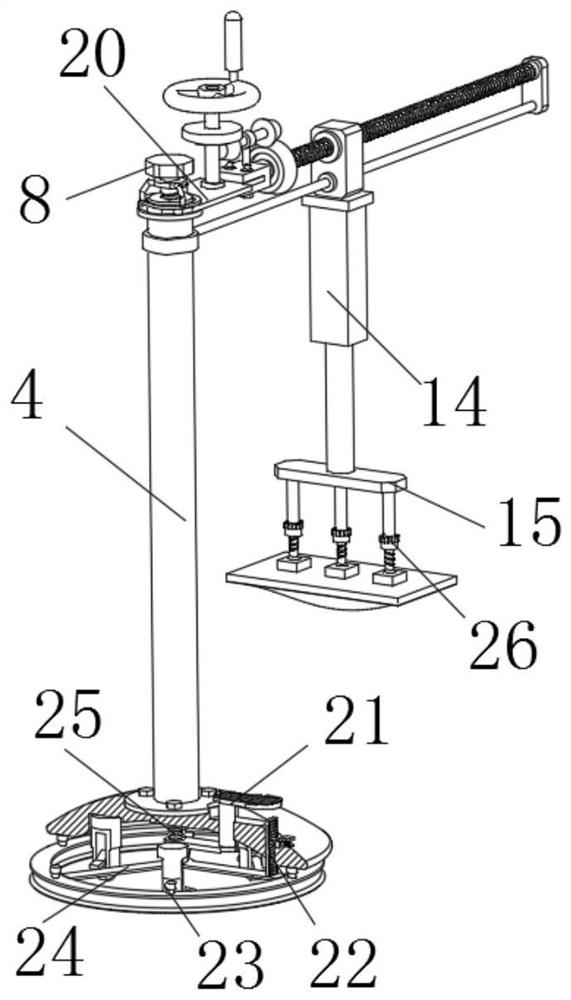

Rescue device for emergency hemostasis in internal medicine department

The invention discloses a rescue device for emergency hemostasis in the internal medicine department, and relates to the field of rescue devices for emergency hemostasis. The rescue device comprises a base, the bottom of the base is provided with a hemostasis rescue device movement limiting part, the top of the base is fixedly connected with a stand column, and the top end of the stand column is rotatably connected with a supporting plate. The rescue device is reasonable in structure, movement and position fixation of the hemostasis rescue device are facilitated by arranging the movement limiting part, compared with a traditional movement fixing mode, the hemostasis rescue device is prevented from moving due to external force, certain adverse effects on the hemostasis effect are avoided, by arranging a hemostasis part, a supporting plate limiting part, a threaded column, a guide rod, a hemostasis rescue device linkage part and an air cylinder assembly, the position of the hemostasis rescue device is adjusted, hemostasis operation is conducted on different bleeding positions, the operation is convenient, the angle of the hemostasis rescue device is flexible, adaptation is conducted according to the shape of the pressed part of a patient, and the hemostasis effect is good.

Owner:JILIN UNIV FIRST HOSPITAL

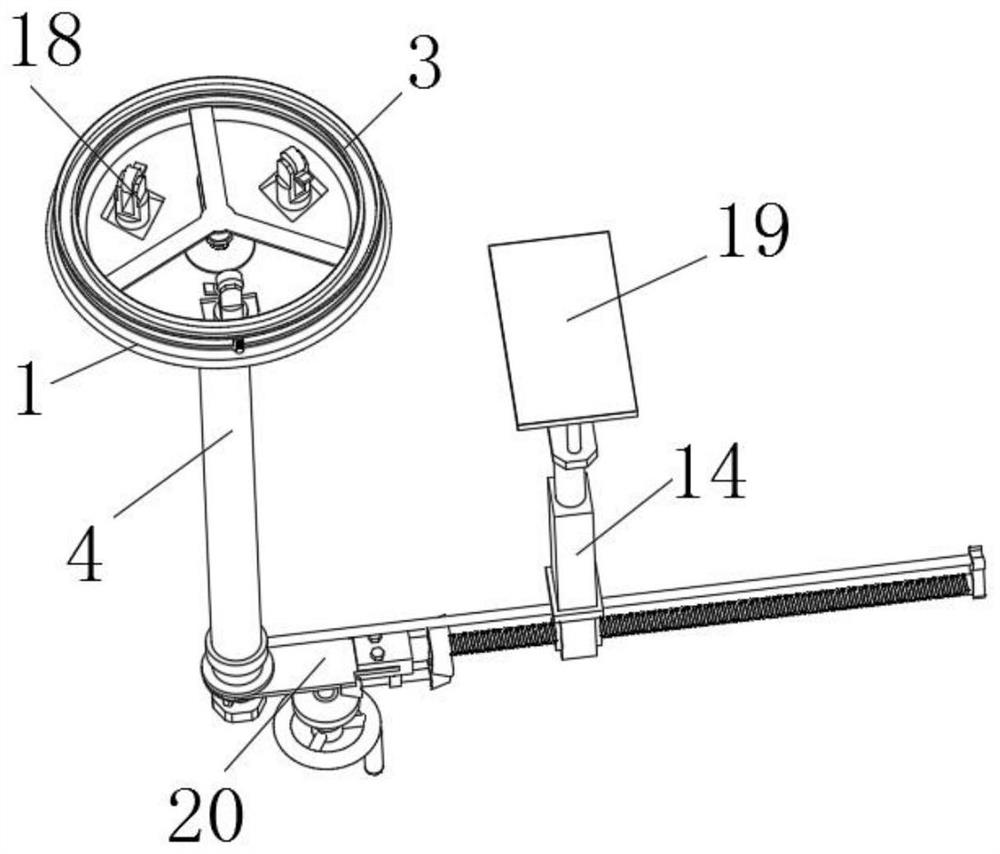

Fixing mechanism with adjustable angle for water conservancy irrigation device

ActiveCN108834833AEasy to adjust irrigation directionEasy to irrigateWatering devicesCultivating equipmentsWater irrigationEngineering management

The invention discloses a fixing mechanism with an adjustable angle for a water conservancy irrigation device. The mechanism comprises a bottom plate, a fixing frame and a limiting plate, a connectingrod is installed above the bottom plate, a fixing plate is arranged above the connecting rod, a side plate is fixed to the part above the fixing plate, a fastening bolt is installed on the left sideof the middle of the side plate, an adjusting screw is fixed to the right side of the fastening bolt, a fixing frame is arranged on the right side of the side plate, a rubber layer is arranged in thefixing frame, a fixing column is welded to the part below the fixing frame, lugs are installed on the two sides of the fixing column, screws are fixed to the upper portions of the lugs, and grounded nails are arranged below the screw lugs. According to the mechanism, a rotary structure is formed by the connecting rod through a rotary disc and the fixing plate, the connecting rod can be rotated through the rotary disc to make the adjustment of the irrigation direction, the rotary range between the connecting rod and the fixing plate is 0-180 degrees, the irrigation range is expanded, and the irrigation is more convenient.

Owner:杭州富阳春江汽车空调厂

Corner machining device for machining mechanical parts

ActiveCN111975516AEasy height adjustmentReduce single sandingEdge grinding machinesGrinding carriagesElectric machineryStructural engineering

The invention relates to the technical field of part machining, and discloses a corner machining device for machining mechanical parts. The corner machining device comprises a first supporting plate,wherein supporting legs are fixedly installed at the bottom of the first supporting plate, movable wheels are arranged at the bottoms of the supporting legs, a second motor is fixedly installed at thebottom of the first supporting plate, a rotary disc is fixedly connected to the output end of the second motor, a push rod is fixedly connected to the surface of the rotary disc, and a supporting pillar is arranged at the top of the first supporting plate. According to the corner machining device for machining the mechanical parts, by pressing a slide block with the hands, then a first reset spring is compressed to draw back, then the height of a grinding machine is conveniently adjusted, and then through the grinding machine, round pipes with different heights are ground. The height limitation to the round pipes during grinding and the grinding monotonousness of the grinding machine are lowered, the situation that the round pipes cannot be ground due to the difference in height of the round pipes is avoided, and the using range of the grinding device is enlarged.

Owner:衡阳嘉准科技有限公司

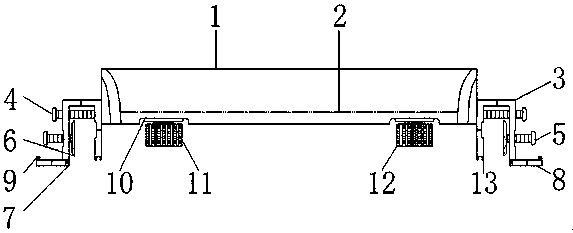

Continuous winding device for carbon fiber prepreg

ActiveCN113026276AImprove the extrusion effectAvoid influenceLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionFiberCarbon fibers

The invention discloses a continuous winding device for carbon fiber prepreg, and belongs to the technical field of carbon fiber prepreg. The continuous winding device comprises two supporting plates, a fixing pipe, a collecting plate and side plates, a base is fixedly connected to the lower surfaces of the two supporting plates, and the fixing pipe is fixedly connected to the upper surfaces of the two supporting plates. According to the continuous winding device for the carbon fiber prepreg, squeezing rollers are arranged, when the infiltrated carbon fiber prepreg passes through the space between the two squeezing rollers, redundant soaking liquid can be squeezed out and flow down; the collecting plate, the side plates and a piston are arranged, the collecting plate is matched with the side plates to collect the flowing-down soaking liquid, the soaking liquid can be collected by opening the piston if recycling is needed, when a pressing plate moves, the pressing plate can be matched with the squeezing rollers to extrude a sponge mat, so that the sponge mat is compressed, and the absorbed soaking liquid can flow out and is collected by the collecting plate; and meanwhile, the dried squeezing rollers squeeze the carbon fiber prepreg again to achieve a better soaking liquid squeezing effect.

Owner:WEIHAI BAOWEI NEW MATERIAL TECH CO LTD

Medical tray with various fixing modes

InactiveCN111616903AAvoid Rollover SituationsEasy to fixNursing accommodationRotational axisIndustrial engineering

The invention discloses a medical tray with various fixing modes. The medical tray comprises a tray main body, first fastening bolts, second fastening bolts and connecting blocks, wherein a tray bottom plate is arranged inside the tray main body, and fixed plates are fixed on left and right walls of the tray main body, the first fastening bolts and the second fastening bolts are both arranged inside the fixed plates, the second fastening bolts are arranged below the first fastening bolts, fixed cushion blocks are fixed on the inner walls of the second fastening bolts, fixed sleeves are arranged below springs, fixed grooves are arranged outside the springs, and rubber cushion blocks are fixed on the inner walls of the fixed sleeves. The medical tray with various fixing modes is provided with support plates, when the tray main body needs to be directly placed on a table top, the support plates can be rotated by rotation of rotating shafts until fixed lugs are buckled with the fixed grooves, so that the support plates can well support the tray main body and ensure placement stability of the tray.

Owner:SHANDONG UNIV QILU HOSPITAL

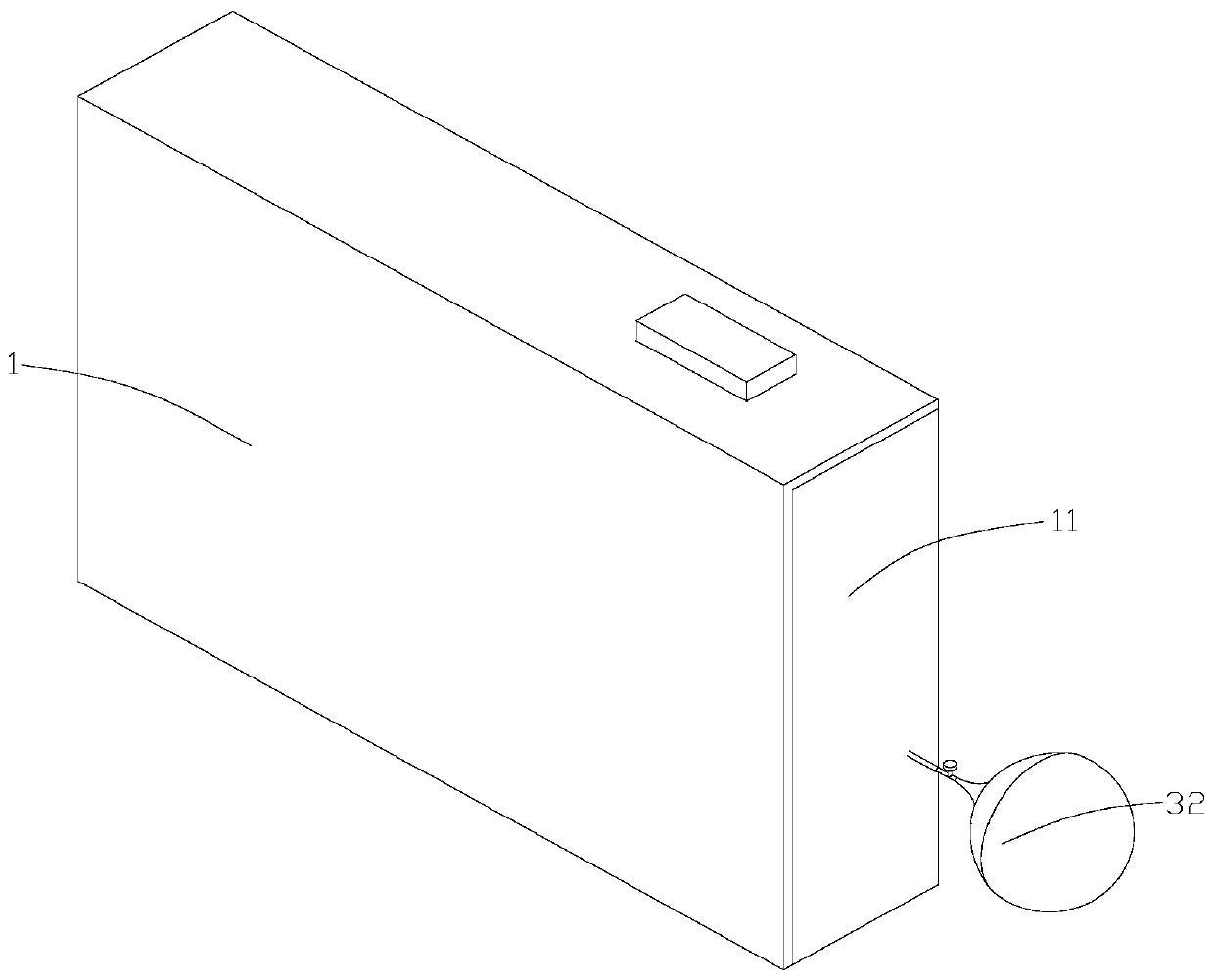

Spectacle lens assembly device convenient to fix

ActiveCN110174780AEffectively fixedGuaranteed stability and reliabilitySpectales/gogglesEyewearEngineering

The invention discloses a spectacle lens assembly device convenient to fix. The spectacle lens assembly device comprises an assembly box body for installing spectacle lenses, wherein the assembly boxbody is internally provided with two fixing blocks for placing and fixing a spectacle frame and a clamping mechanism for fixing the spectacle lens on the fixing blocks, further, the assembly box bodyis internally provided with a placement box for placing the spectacles lenses, and the placement box is provided with an active overturn plate controlling the opening of the placement box to open andclose. Through adoption of the spectacle lens assembly device, the spectacle lenses can be fixed through cooperation of the placement box and the active overturn plate, so that the spectacle lenses are prevented from deviating when being sucked and fixed, and are guaranteed to be stable.

Owner:浙江泰德光学有限公司

Winding device for textile

The invention discloses a winding device for textile. The winding device comprises a base and a winding drum, wherein the winding drum is supported by a supporting seat arranged on the base; an accommodating space with the two ends being penetrated completely is arranged on the winding drum; the accommodating space is provided with a strip-shaped opening communicating with the outer wall of the winding drum; the side wall of the strip-shaped opening is arc-shaped; a positioning column is arranged in the accommodating space; a first electric push rod is fixed on the inner side wall of the accommodating space; and the end part of the first electric push rod is fixedly connected with the center of an arc-shaped fixing piece. According to the winding device, the accommodating space and the strip-shaped opening are arranged, so that textile is wound directly without manual pre-winding when the textile is wound, and the labor intensity of labor workers is reduced; the side wall of the strip-shaped opening is arc-shaped, so that damage to cloth caused by the too sharp side wall of the strip-shaped opening is avoided; and furthermore, the connecting point of the fixing piece and the firstelectric push rod is at the middle position of the fixing piece, so that the radian of the fixing piece is adjusted to adapt to the textiles with different thicknesses.

Owner:宿迁至诚纺织品股份有限公司

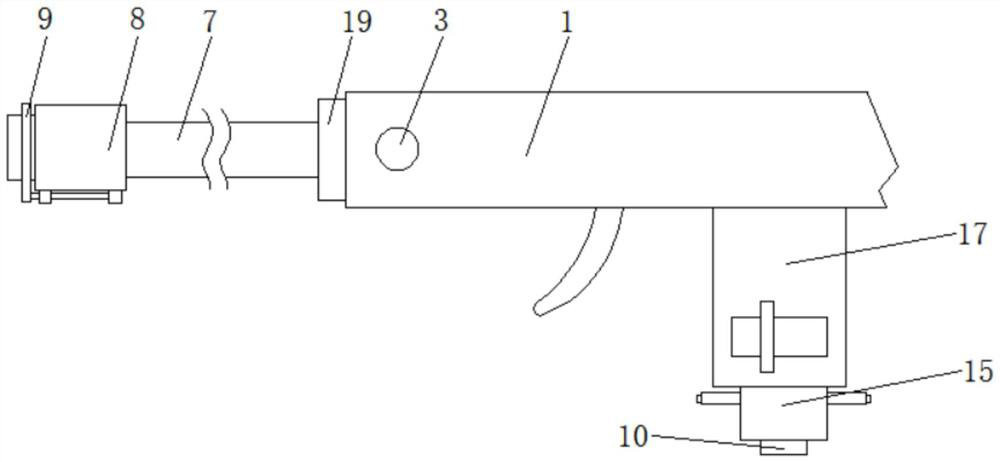

Combined stainless steel multi-ring elastic thread anorectal ligation device

PendingCN112244931AAvoid labor lossReduce extrusion pressureDiagnosticsExcision instrumentsApparatus instrumentsScrew thread

The invention discloses a combined stainless steel multi-ring elastic thread anorectal ligation device, and relates to the technical field of medical instruments. The ligation device comprises a machine body; threaded holes are formed in the two sides of the machine body; studs are placed on the inner sides of the threaded holes; one sides of the studs are in threaded connection with sliding blocks; the inner sides of the sliding blocks are connected with sliding rods; a limiting plate is fixedly connected to one side of the tail end of each sliding rod; a handle is welded to the bottom end ofthe machine body; and a negative pressure connector is formed in the bottom end of the handle. According to the invention, due to the fact that a movable plate is installed on the outer side of the negative pressure connector, a user can conveniently drive the movable plate through push rods to push a negative pressure connecting tube connected to the negative pressure connector in a sleeving mode, then the user can conveniently and rapidly disassemble the negative pressure connecting tube, and the labor force loss of the user due to inconvenience in disassembly work can be effectively avoided; and in addition, due to the existence of sponge mats, the extrusion force of the push rods on the palms of the user can be greatly reduced.

Owner:CHANGZHOU ANKANG MEDICAL EQUIP

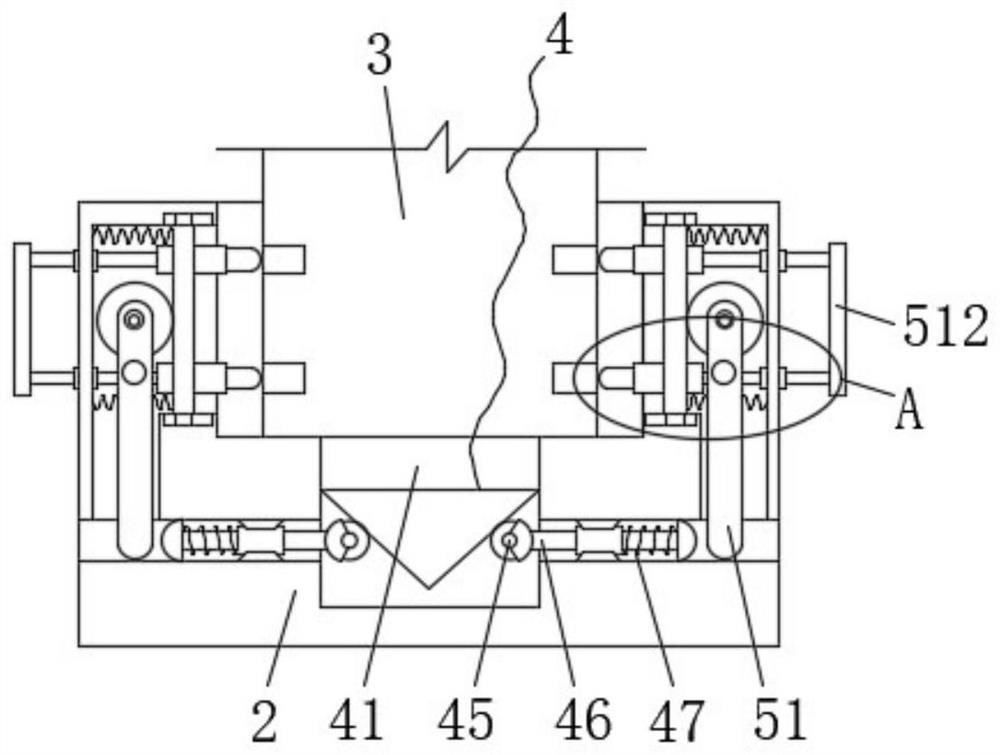

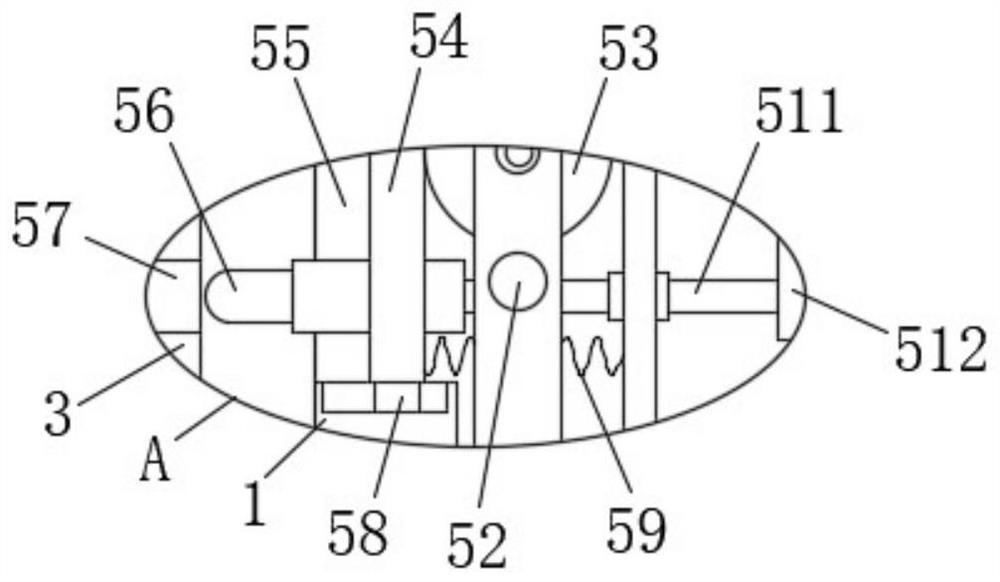

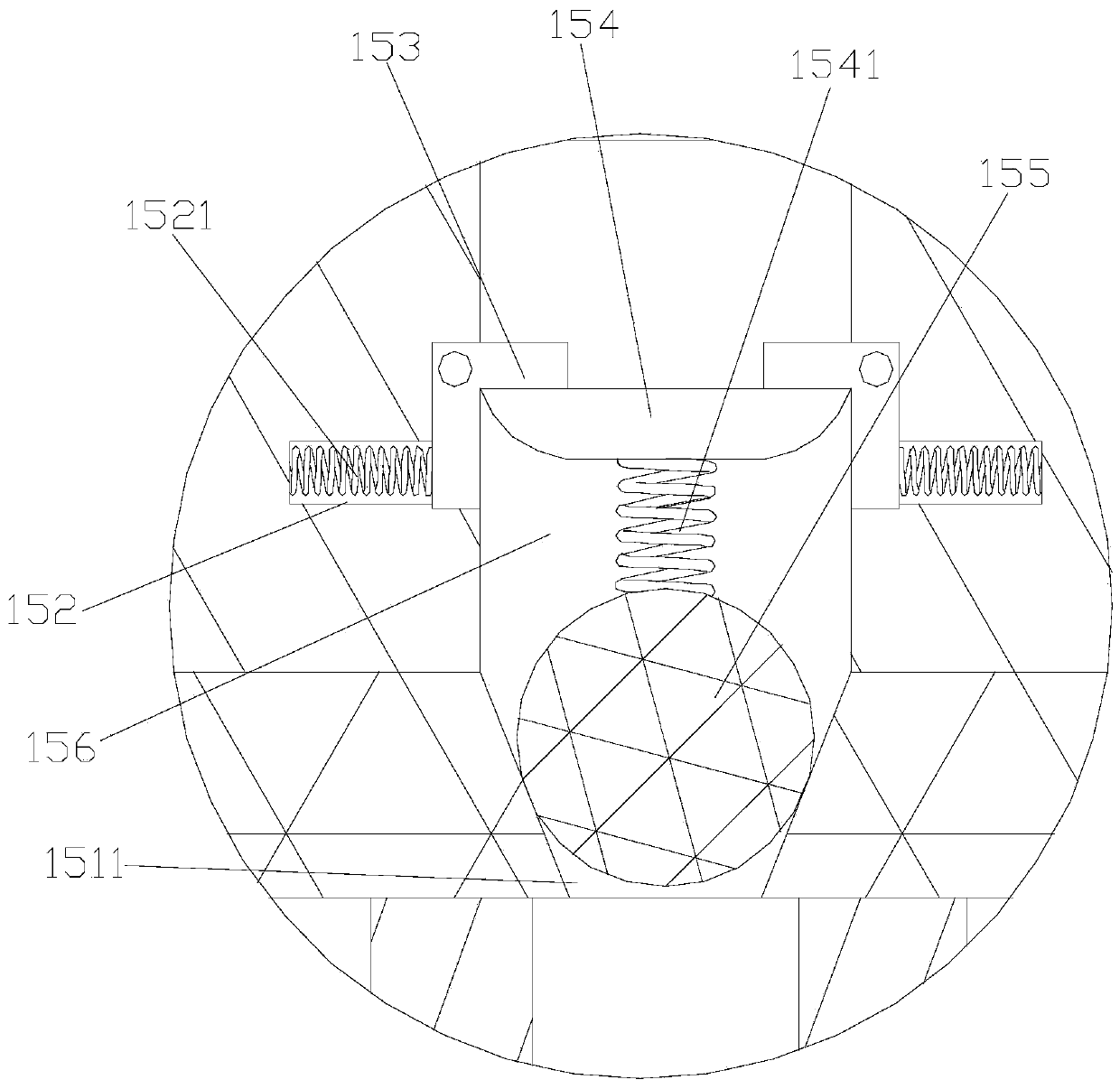

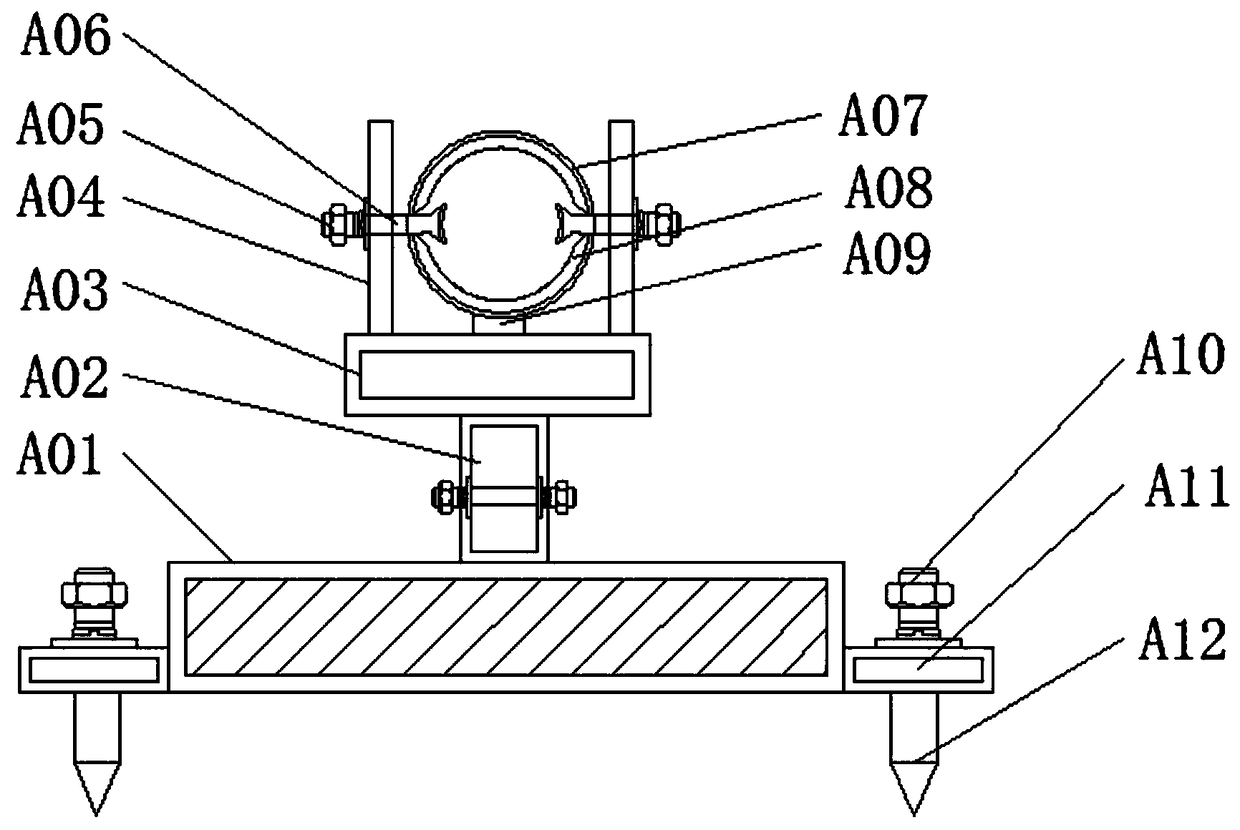

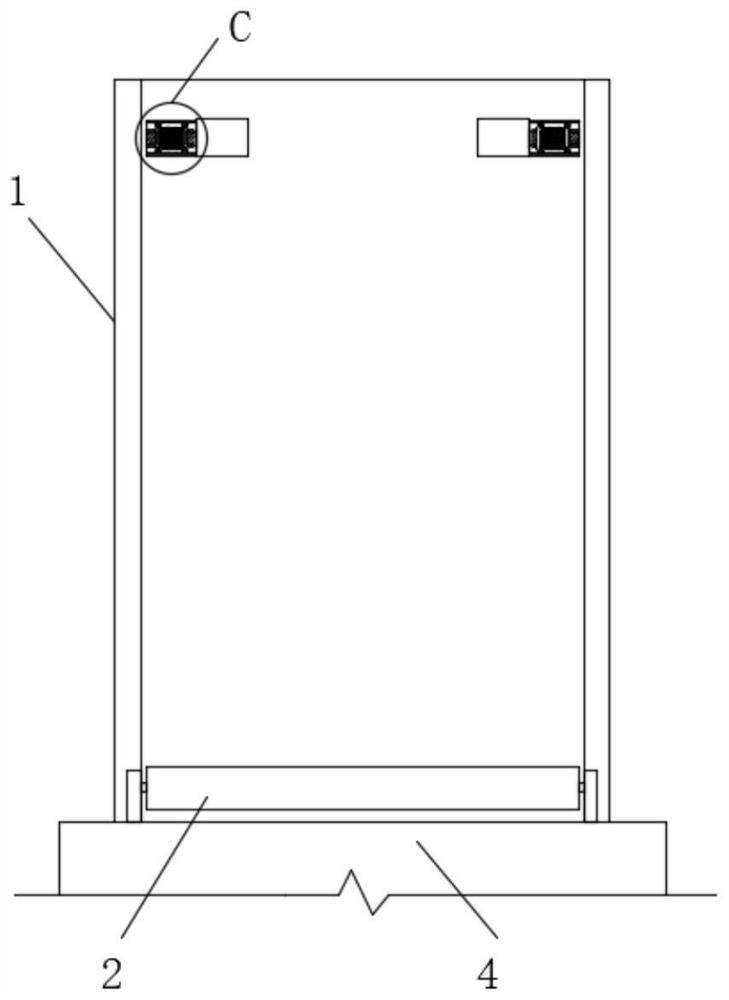

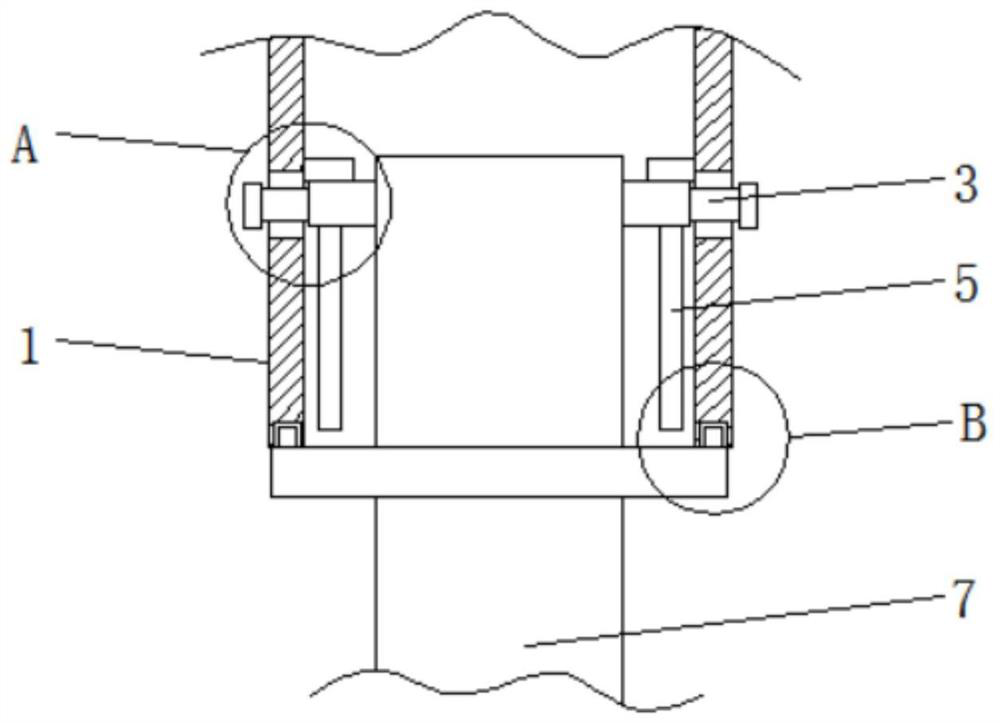

Optical fiber gyroscope convenient to mount

The invention relates to an optical fiber gyroscope convenient to mount, which comprises a mounting seat, wherein a gyroscope placing mechanism is arranged on the upper surface of the mounting seat, two clamping mechanisms are symmetrically arranged on the upper surface of the mounting seat relative to the gyroscope placing mechanism, two clamping mechanisms are arranged in the mounting seat, two fixing mechanisms are symmetrically arranged in the mounting seat relative to the gyroscope placing mechanism, a first conveying mechanism is arranged in each of the two clamping mechanisms, a second conveying mechanism is arranged in each of the two fixing mechanisms, two transmission mechanisms are symmetrically arranged in the mounting seat, the two transmission mechanisms are connected with the first conveying mechanism and the second conveying mechanism correspondingly, and the ends, which are away from each other, of the two transmission mechanisms extend out of the mounting base and are provided with rotating mechanisms. The optical fiber gyroscope is simple and convenient, and the rotating rod is reversely rotated during disassembly.

Owner:TIANJIN NAVIGATION INSTR RES INST

Skin nailing machine for steamed pork

The invention discloses a skin nailing machine for steamed pork. The skin nailing machine comprises an equipment device body, a first fixed supporting column and a second fixed supporting column, wherein the first fixed supporting column is fixedly connected with and arranged at one end of the equipment device body; the second fixed supporting column is fixedly connected with and arranged at the other end of the equipment device body; a sliding groove is fixedly connected with and arranged on the inner wall of one end of the first fixed supporting column; a convenient plug-in unit is fixedly connected with and arranged at the top end of a limiting groove; and a fixed plate is fixedly connected with and arranged at the top end of the convenient plug-in unit. According to the invention, theconvenient plug-in unit is a small steamed pork nail, so punching of small steamed pork is facilitated; the top part of the convenient plug-in unit is provided with the fixed plate used for placementand convenient taking, so practicability is embodied; a placement hole is fixedly arranged in the limiting groove and used for storing the convenient plug-in unit; when the convenient plug-in unit isnot in use, the convenient plug-in unit can be put back into the placement hole; the sliding groove is fixedly arranged at two ends of two supporting columns, so movement of a pressing plate is limited within a certain range; and thus, the skin nailing machine provided by the invention is applicable to being used for making the steamed pork, and has wide development prospect in the future.

Owner:周济扬

High-precision fixing device for machining

InactiveCN111300091AImprove clamping effectImprove conveniencePositioning apparatusMetal-working holdersSplint deviceRetainer (device)

The invention discloses a high-precision fixing device for machining. The high-precision fixing device for machining comprises a fixing base, wherein sliding grooves are formed in the outer walls of the two sides of the fixing base; sliding blocks are slidably connected to the inner walls of the two sliding grooves; L-shaped plates are fixedly connected to the outer walls of one sides of the two sliding blocks; supporting seats are fixedly connected to the outer walls of one sides of the two L-shaped plates and one side of the top outer wall of the fixing base; second fixing grooves are formedin the top outer walls of the two supporting seats; second protective pads are bonded to the inner walls of the two second fixing grooves; a plurality of ribs are arranged on the inner wall of each second protective pad correspondingly; and a plurality of fixing teeth are arranged on the outer wall of one side of each rib correspondingly. When the high-precision fixing device for machining works,a workpiece can be prevented from rolling due to acting force so that the machining deviation of the workpiece can be avoided, the offsetting between clamping plates and the supporting seats due to shaking of the clamping plates when the clamping plates move is avoided, the influence on fixing of the workpiece due to the fact that the workpiece is too short or too long is eliminated, and thus theworking convenience of the device is improved.

Owner:王菊

Cutting machine servo limiting device convenient to adjust

The invention provides a cutting machine servo limiting device convenient to adjust. The cutting machine servo limiting device comprises a planet wheel speed reducer, mounting flange plates, a driving shaft, a rotating angle limiting frame structure, an elastic lifting frame structure, a transverse moving limiting frame structure, a telescopic wire hoisting frame structure, a mounting bolt, a sliding block coupler, a servo motor, a connecting flange plate and an encoder connecting socket; the mounting flange plates are welded to the left side and the right side of the outer portion of the planet wheel speed reducer correspondingly; and the driving shaft is mounted in the middle of the right side of the planet wheel speed reducer. The cutting machine servo limiting device has the beneficial effects that through the arrangement of a connecting sleeve, a semicircular protrusion, a sliding block, a center ejector rod and a bottom limiting switch, the rotating angle of the driving shaft can be limited, the driving shaft is made to support the rotating fixed angle, and the situation that the precision of a cutting machine is reduced due to the fact that the rotating angle of the driving shaft is too large is prevented.

Owner:YANTAI AUTOMOBILE ENG PROFESSIONAL COLLEGE

Medical tray with multiple fixing modes

ActiveCN107753219AAvoid Rollover SituationsEasy to fixSurgical furnitureNursing accommodationEngineeringMedical treatment

The invention discloses a medical tray with multiple fixing modes. The tray comprises a tray main body, a first fastening bolt, a second fastening bolt and a connection block, a tray baseplate is arranged in the tray main body, and fixing plates are fixed to the left wall and the right wall of the tray main body; the first fastening bolt and the second fastening bolt penetrate through the fixing plates and are arranged in the fixing plates, the second fastening bolt is arranged below the first fastening bolt, and a fixing cushion block is fixed to the inner wall of the second fastening bolt; afixing sleeve is arranged below a spring, a fixing groove is formed in the outer side of the spring, and a rubber cushion block is fixed to the inner wall of the fixing sleeve. According to the medical tray with multiple fixing modes, a supporting plate is arranged, when the tray main body needs to be directly placed on a table top, the supporting plate can be rotated through rotation of a rotation shaft until a fixing protruding block is buckled with the fixing groove, accordingly, the supporting plate can well support the tray main body, and the placement stability of the tray is guaranteed.

Owner:浙江兰思教育科技有限公司

A highly stable water-cooled motor shell testing equipment

ActiveCN109916571BFixed effectEasy to fixDetection of fluid at leakage pointMeasurement of fluid loss/gain rateElectric machineryScrew thread

The invention discloses a highly stable water-cooled motor casing testing device, which comprises a testing frame and a control box, the bottom of the testing frame is provided with a first sealing gasket, and the top of the testing frame is provided with a first fixing device, the inner wall of the detection frame is provided with a water pipe, and the water pipe is provided with a plurality of water nozzles; the first sealing pad is provided with an air pressure sensor, and the air pressure sensor is connected to the control box through a wire connected; the fixing device includes a rotatable nut seat arranged in the detection frame, a threaded rod pierced in the nut seat and a lower pressing plate arranged at the bottom of the threaded rod, and the top of the threaded rod is provided with There is a first limiting plate, a through hole is arranged on the first limiting plate, a second fixing device is arranged in the through hole, and a limiting device is arranged on the top of the detection frame; through the second fixing device and the limiting The cooperation of the positioning device prevents the nut seat and the threaded rod from shaking, and improves the fixing effect of the first fixing component on the motor housing.

Owner:SHANDONG CHENXIN NEW ENERGY

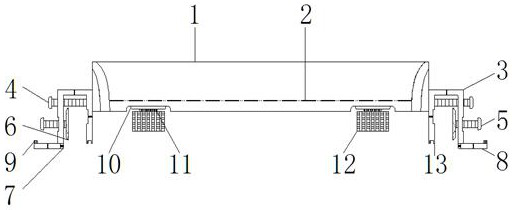

Cross hole drilling machine

ActiveCN102528119BPlay the role of positioningAccurate locationAutomatic control devicesFeeding apparatusBatch processingEngineering

The invention discloses a cross hole drilling machine which comprises a machine body, wherein the machine body is provided with a clamping device and a fixing device; the clamping device and the fixing device are used for positioning a processed piece; the machine body is provided with a main bracket; the main bracket is provided with a main electric drill by a feeding mechanism; the main bracketis also provided with an auxiliary electric drill by the feeding mechanism; the axis of the auxiliary electric drill and the axis of the main electric drill are vertical and are positioned in the same plane; the machine body is provided with a controller which controls the main electric drill, the auxiliary drill and the feeding mechanism to carry out logic work; the input end of the controller is electrically connected with a control button; the machine body is also provided with an auxiliary bracket; the auxiliary bracket is provided with a main auxiliary electric drill and an assistant auxiliary electric drill by the feeding mechanism, wherein the axis of the main auxiliary electric drill and the axis of the assistant auxiliary electric drill are vertically arranged in the same plane; and the machine body is provided with an electric control switch which controls the main auxiliary electric drill and the assistant auxiliary electric drill to feed by the controller. The cross hole drilling machine of the structure has the advantages of reasonable structure, high processing precision and high processing efficiency, is convenient to operate and is especially suitable for batch processing.

Owner:RIZHAO SHIZHENG FORGING

Screwing positioning tool, screwing structure and screwing method

InactiveCN103419144AFixed effectPrevent missWork holdersMetal-working hand toolsScrew positionEngineering

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Non-dilution blower device for high-efficiency water heater

InactiveCN109520134AImprove sound insulationEasy to installFluid heatersPump componentsEngineeringExhaust pipe

The invention discloses a non-dilution blower device for a high-efficiency water heater. The non-dilution blower device comprises a water heater roof and a flue pipe, the top end of the water heater roof is provided with the flue pipe, the bottom end of the flue pipe is fixedly connected to the top end of the water heater roof through welding, the bottom end of the flue pipe is perpendicular to the water heater roof to be in a circular through shape, a water heater exhaust pipe is arranged below the flue pipe, the top end of the water heater exhaust pipe is fixedly connected to the circular through shaped bottom end of the water heater roof through welding, an air plate device is arranged at the top end inside the flue pipe, the air plate device is movably connected to the interior of theflue pipe through welding, the flue pipe is connected with the air plate device in a sleeve manner, and a quartz acoustic panel and the surface of a motor are not connected, the quartz acoustic panelis fixed to the outer surface of the motor through self gravity, the quartz acoustic panel can be conveniently installed and disassembled, and the non-dilution blower device is more humanized and relatively practical.

Owner:ZHONGSHAN CITY HENG YUE ELECTRICAL APPLIANCE CO LTD

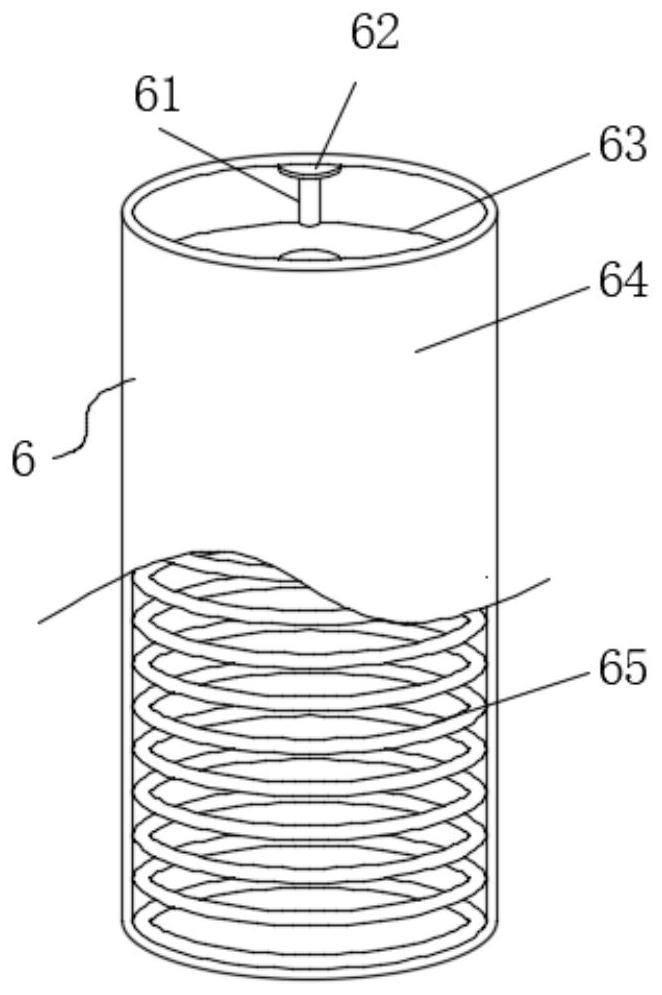

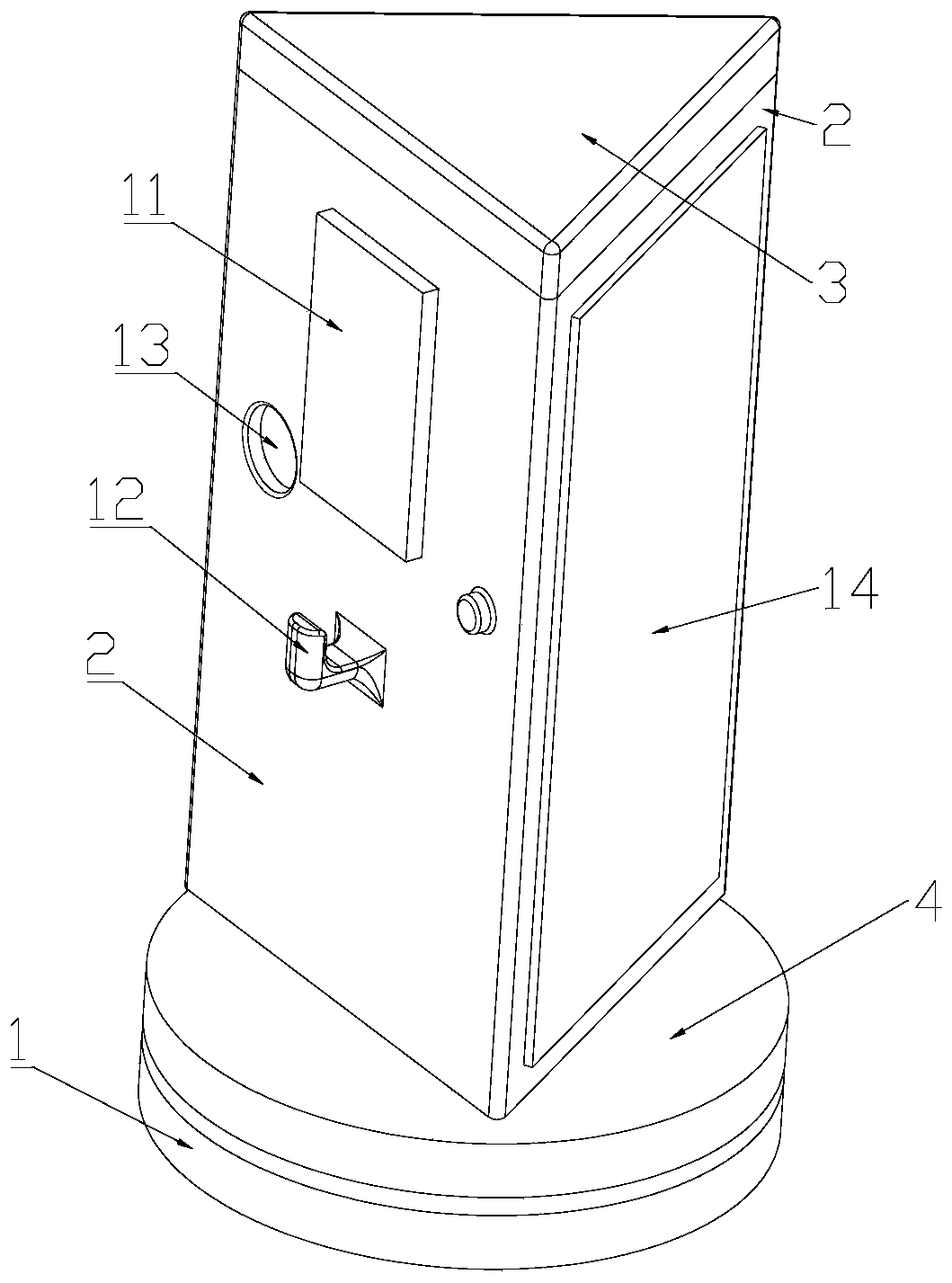

Outdoor charging pile shell

InactiveCN110450668AFixed effectExtended service lifeCharging stationsElectric vehicle charging technologyElectric devicesTriangular prism

The invention discloses an outdoor charging pile shell. The outdoor charging pile shell comprises three side faces, a cover plate and a circular bottom plate, a triangular prism is surrounded by the three side faces, an electric appliance mounting cavity is formed in the triangular prism, the upper end of the triangular prism is detachably covered with the cover plate, the triangular prism is fixed to the circular bottom plate, a fixing seat is arranged on the lower part of the circular bottom plate, a vertically-arranged spring is arranged between the circular bottom plate and the fixing seat, the two ends of the spring are fixedly connected with the circular bottom plate and the fixing seat correspondingly, cable wiring holes are formed in the circular bottom plate and the fixing seat correspondingly, the cable wiring hole in the circular bottom plate corresponds to the cable wiring hole in the fixing seat, the cable wiring hole in the circular bottom plate and the cable wiring holein the fixing seat directly face the spring, a plurality of supporting columns are fixed to the fixing seat, and the supporting columns jack the lower surface of the circular bottom plate. According to the outdoor charging pile shell, the safety of internal electric devices can be effectively protected, the situation that connecting between a charging pile and the fixing seat is loosened due to long-term shaking of the charging pile because of wind blowing, collision and the like is not prone to occurring, the service life of the charging pile is prolonged, and the electrical safety of the charging pile is improved.

Owner:凡泽模塑(嘉善)有限公司

A continuous winding device for carbon fiber prepreg

ActiveCN113026276BImprove the extrusion effectEvenly paintedLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionFiberPolymer science

The invention discloses a continuous winding device for carbon fiber prepreg, which belongs to the technical field of carbon fiber prepreg, and includes a support plate, a fixed pipe, a collecting plate and a side plate. The number of the support plates is two, two The lower surface of the support plate is fixedly connected with the base, and the upper surfaces of the two support plates are fixedly connected with the fixed pipe. In the present invention, by setting squeeze rollers, when the infiltrated carbon fiber prepreg passes between the two squeeze rollers, the excess soaking liquid will be squeezed out and flow, and by setting collecting plates, side plates and pistons, the collecting plate Cooperate with the side plate to collect the falling soaking liquid. If it needs to be recycled and reused, the soaking liquid can be collected by opening the piston. When the pressing plate moves, it can cooperate with the squeeze roller to squeeze the sponge pad, so that the sponge pad is compressed and absorbed. The soaking liquid can flow out and be collected by the collecting plate, and at the same time, the dry extrusion roll will squeeze the carbon fiber prepreg again to achieve a better soaking liquid extrusion effect.

Owner:WEIHAI BAOWEI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com