Cross hole drilling machine

A technology of cross hole and drilling machine, which is applied in the direction of boring/drilling, drilling/drilling equipment, clamping, etc. It can solve the problems of complex structure, collision of two drills, cumbersome operation process, etc., to achieve accurate position and improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

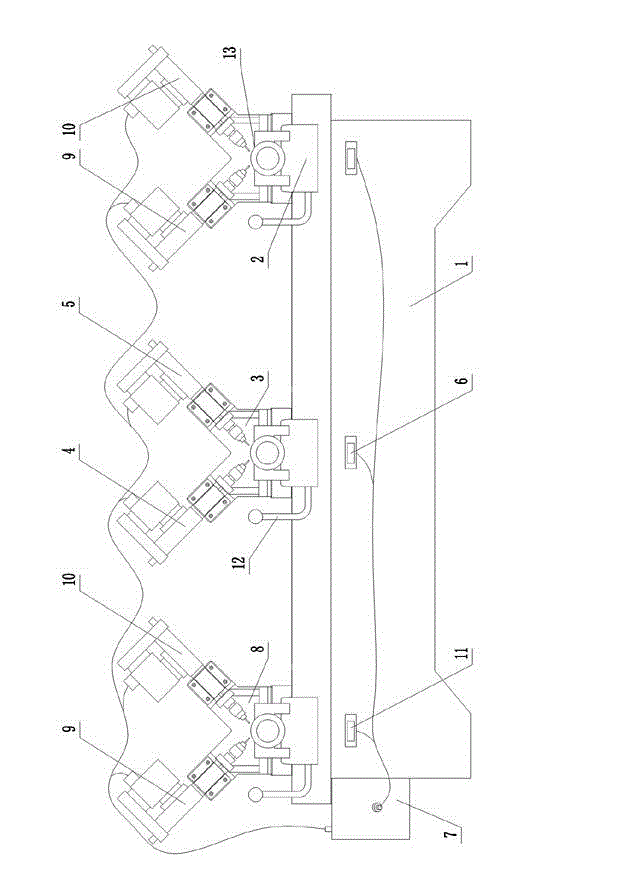

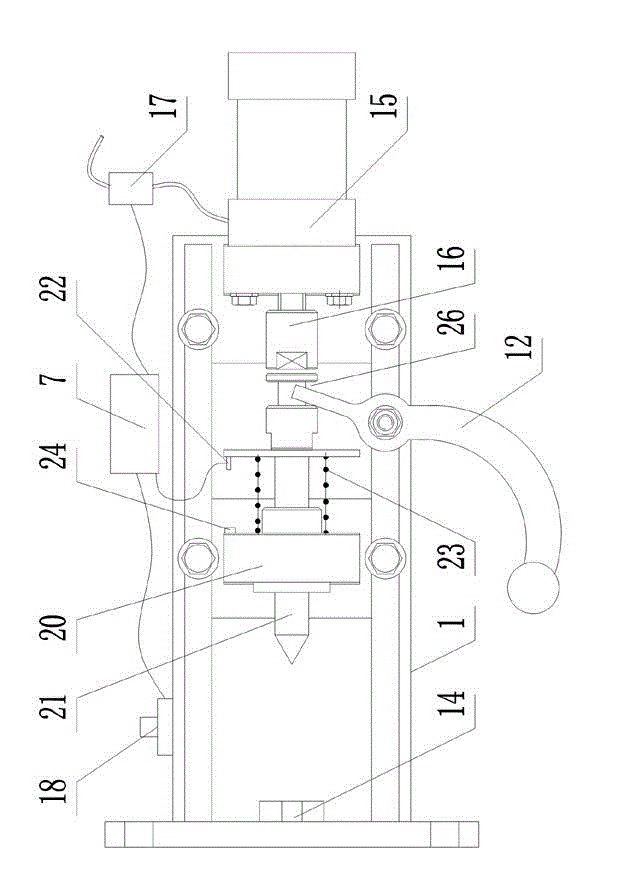

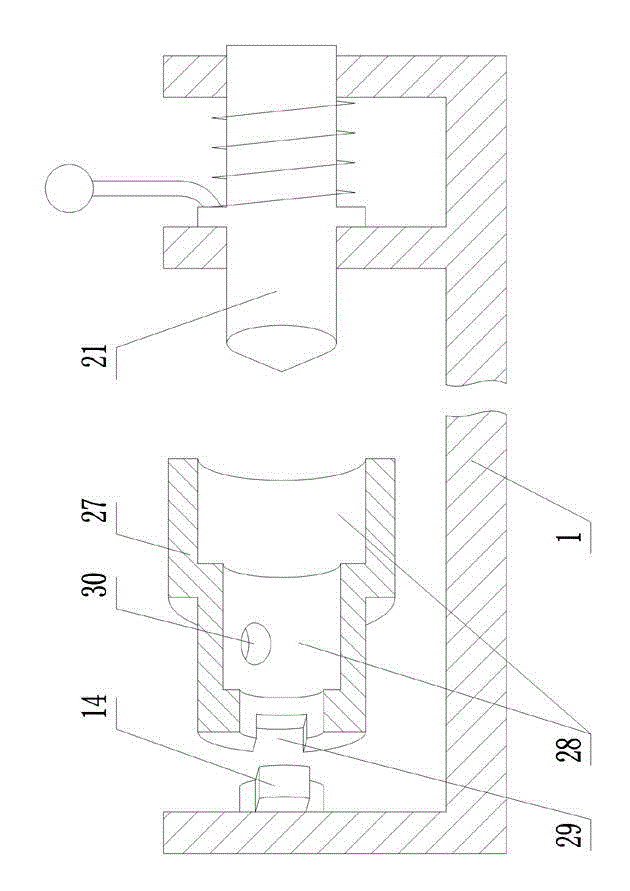

[0027] Such as figure 1 As shown, the cross-hole drilling machine includes a bed body 1 on which a main support 3 and a clamping device 2 and a fixing device 13 used in conjunction with the main support 3 are installed. A push-pull rod 12 is installed on the clamping device 2 , and the loosening and clamping of the clamping device 2 can be controlled by pushing and pulling the push-pull rod 12 . The main functions of the clamping device 2 and the fixing device 13 are to clamp and position the workpiece to be processed on the table surface of the bed body 1 corresponding to the main support 3, so as to facilitate processing and drilling.

[0028]The main bracket 3 is equipped with a main electric drill 4 and an auxiliary electric drill 5 through a feed mechanism, the axis of the main electric drill 4 and the axis of the auxiliary electric drill 5 are vertically arranged, and the axes of the two electric drills are located in the same plane, so that the processed The vertical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com