Mechanical continuous mining method for hard rock

A mining method and hard rock technology, which is applied in the field of mechanized continuous mining of hard rock, can solve problems such as low efficiency, small scale, and sensitive mining costs, and achieve the effects of high mining safety, large production capacity, and small stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Xunyang County Zhongbao Mining Co., Ltd. Gangou lead-zinc mine is a typical gently inclined thin ore body in China. The shape of the ore body is mainly layered. Zinc ore, the average zinc grade of the ore body is 3.93%; the ore body is generally inclined to the northeast, with a dip angle of 10°-35°, and the thickness of the ore body is 1.00-2.00m, with an average thickness of 1.64m. In order to realize the economic benefits of the mine, a hard rock mechanized continuous mining method according to the present invention was tested in the middle section of 500m. The panel production capacity is 450-500t / d, and the mining cost is 8.45 yuan / t, and the effect is good. A specific implementation of a hard rock mechanized continuous mining method in Gangou lead-zinc mine is as follows:

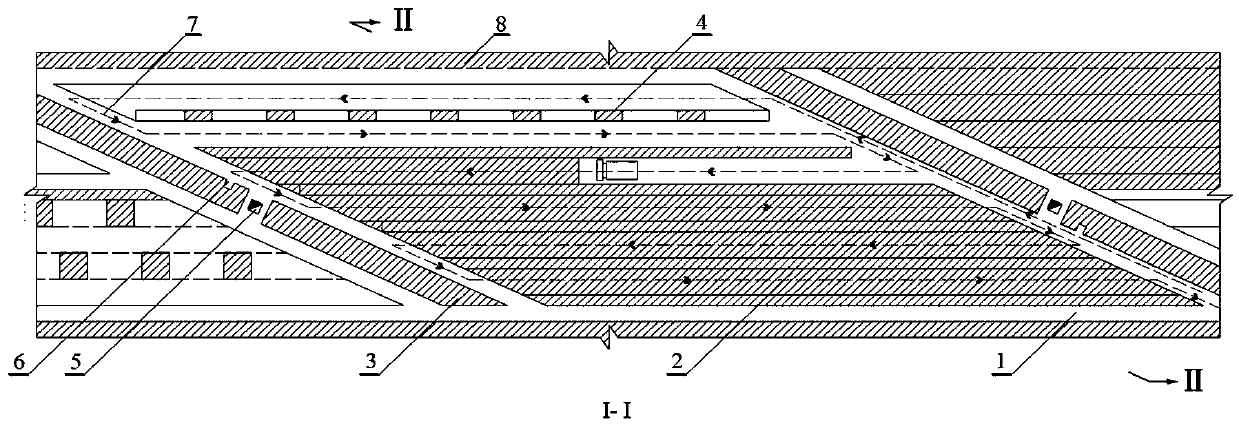

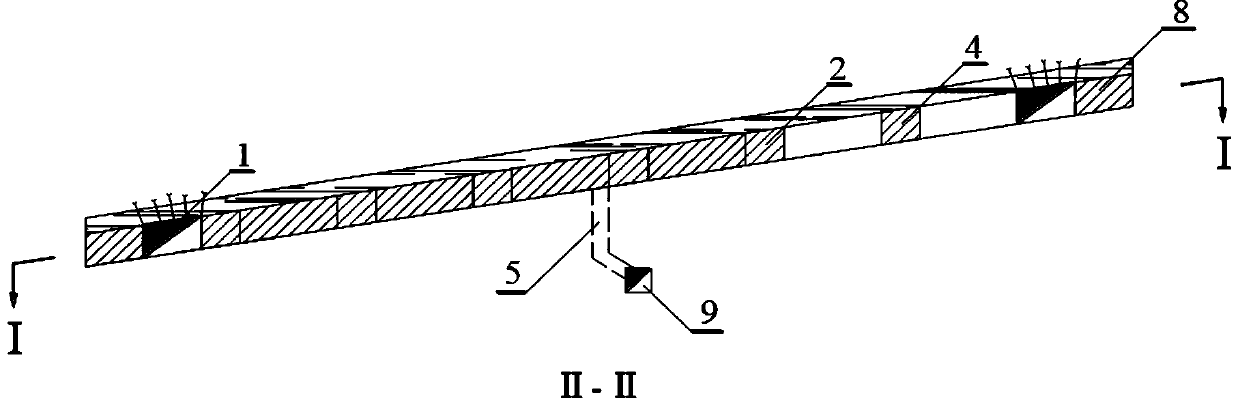

[0019] Such as Figure 1-2 Shown, a kind of hard rock mechanized continuous mining method comprises the following steps:

[0020] 1) Structural parameter division: Arrange the panel along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com