Method and pump pressure protection system for preventing misoperation of drilling pump in petroleum drilling engineering

A technology for oil drilling and protection systems, applied in pump control, pump testing, liquid displacement machinery, etc., can solve problems such as suffocation of pumps, inability to judge whether high-pressure valves are closed, etc., to prevent misoperation accidents of drilling pumps , Realize the effect of pump pressure safety protection and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The method for preventing the misoperation of the drilling pump in the petroleum drilling engineering of the present invention, the realization process is as follows:

[0025] 1) Install a pressure sensor on the standpipe to detect the mud pressure P0 in the standpipe;

[0026] Install a pressure sensor Ⅰ on the pipeline at the outlet of the drilling pump Ⅰ to detect the pressure P1 of the drilling pump Ⅰ;

[0027] Install a pressure sensor II on the pipeline at the outlet of the drilling pump II to detect the pressure P2 of the drilling pump II;

[0028] 2) Set the average value of the mud pressure difference in the upstream and downstream pipelines of the high pressure valve as n under normal working conditions, and set the parameter N in combination with the parameters of the drilling equipment used, and the parameter N satisfies: 1≤N-n≤3;

[0029] When the drilling pump is started, the controller compares the pressure P0 in the standpipe, the pressure P1 of the dri...

Embodiment 2

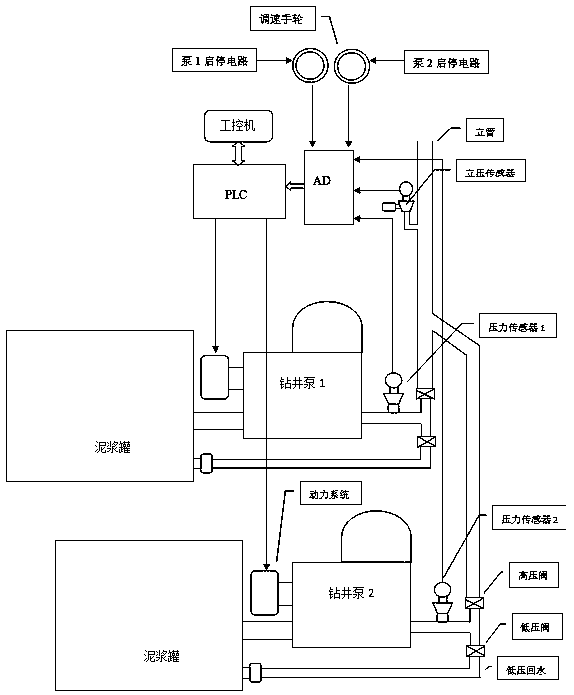

[0036] The pump pressure protection system for preventing the misoperation of the drilling pump in the petroleum drilling engineering of the present invention includes a standpipe pressure sensor, a controller and an actuator, corresponding to the drilling pump I and the drilling pump II as the common drilling pump and the standby drilling pump, respectively setting the pump pressure The detection sensor, the output signals of the standpipe pressure sensor and the pump pressure detection sensor are respectively connected to the controller through the AD analog-to-digital converter, and are connected to the controller with two control mechanism outputs to control and connect the drilling pump I and the drilling pump II respectively. According to the monitoring and judging method described in claim 1, the controller recognizes the misoperation of the drilling pump, and controls the starting and stopping of the drilling pump I or the drilling pump II through the corresponding contr...

Embodiment 3

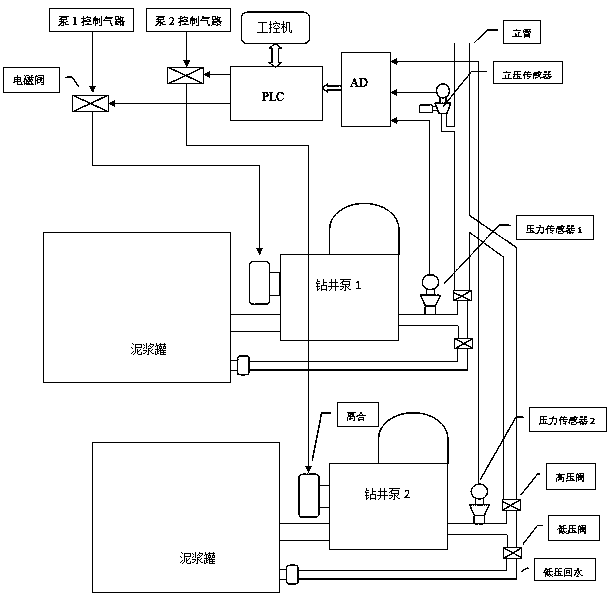

[0038] see figure 1 , the pump pressure protection system for oil drilling engineering in this embodiment to prevent misoperation of drilling pumps is different from Embodiment 2 in that further, for mechanical drilling pumps, the actuator adopts a pneumatic control system, and the controller outputs two control signals The control solenoid valve of the drilling pump I and the control solenoid valve of the drilling pump II are respectively connected, and the clutch controller of the drilling pump is connected through the solenoid valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com