Hydraulic cylinder and tunnel boring machine

A technology of hydraulic cylinders and cylinders, applied in tunnels, fluid pressure actuation devices, mining equipment, etc., can solve the problems of low degree of freedom of the sensor body and the long time required for sensor replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

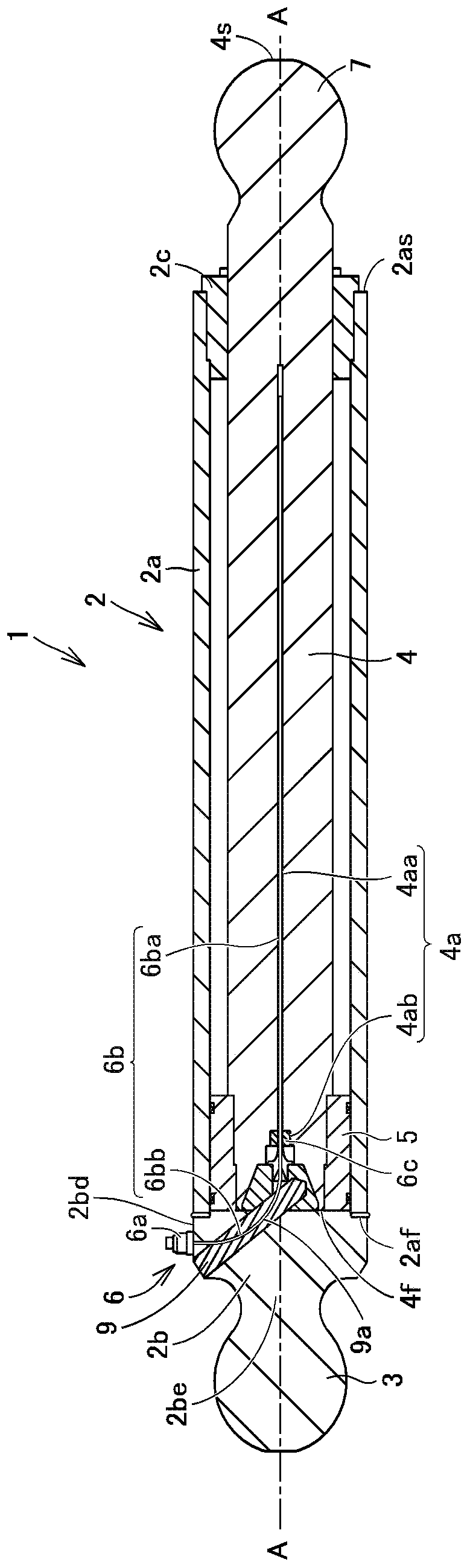

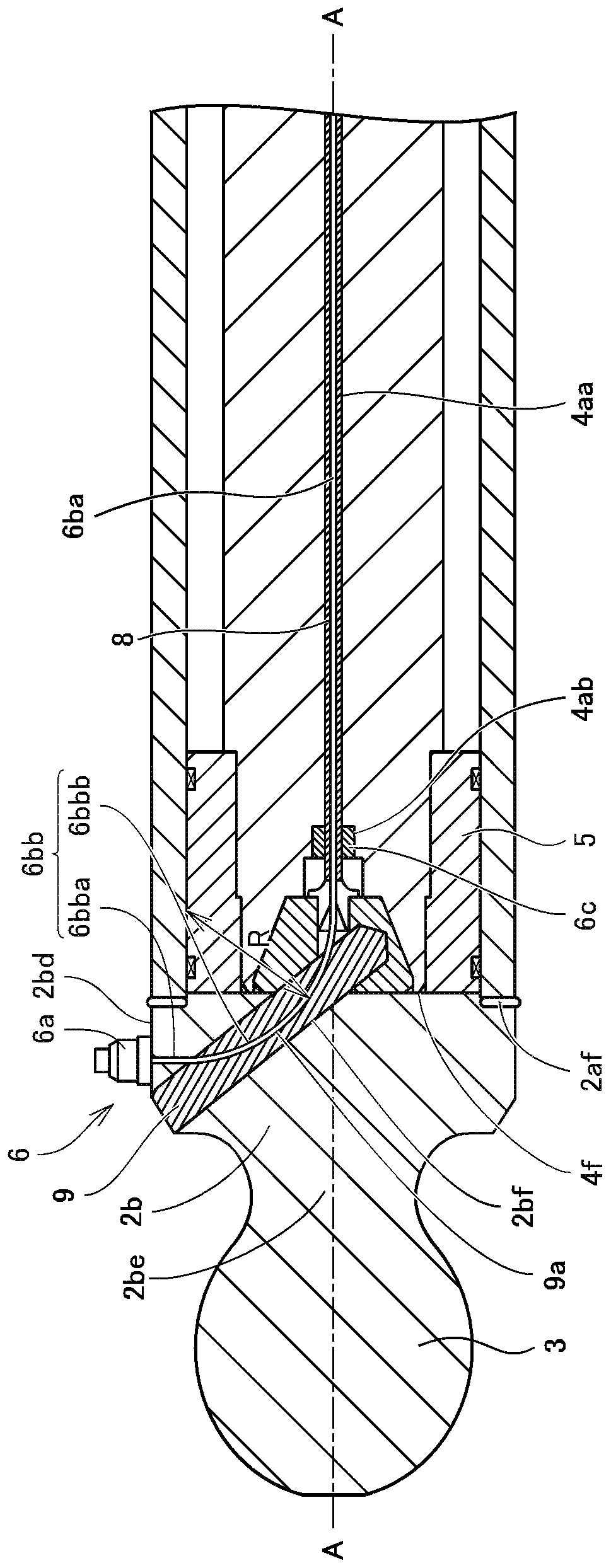

[0012] Hereinafter, embodiments of the present invention will be described based on the drawings. It should be noted that, in the specification and the drawings, the same constituent elements or corresponding constituent elements are assigned the same reference numerals, and repeated descriptions are not repeated. In addition, in the drawings, the structure may be omitted or simplified for convenience of description.

[0013] (Structure of tunnel boring machine)

[0014] First, the structure of a tunnel boring machine to which the hydraulic cylinder of the present invention can be applied will be described.

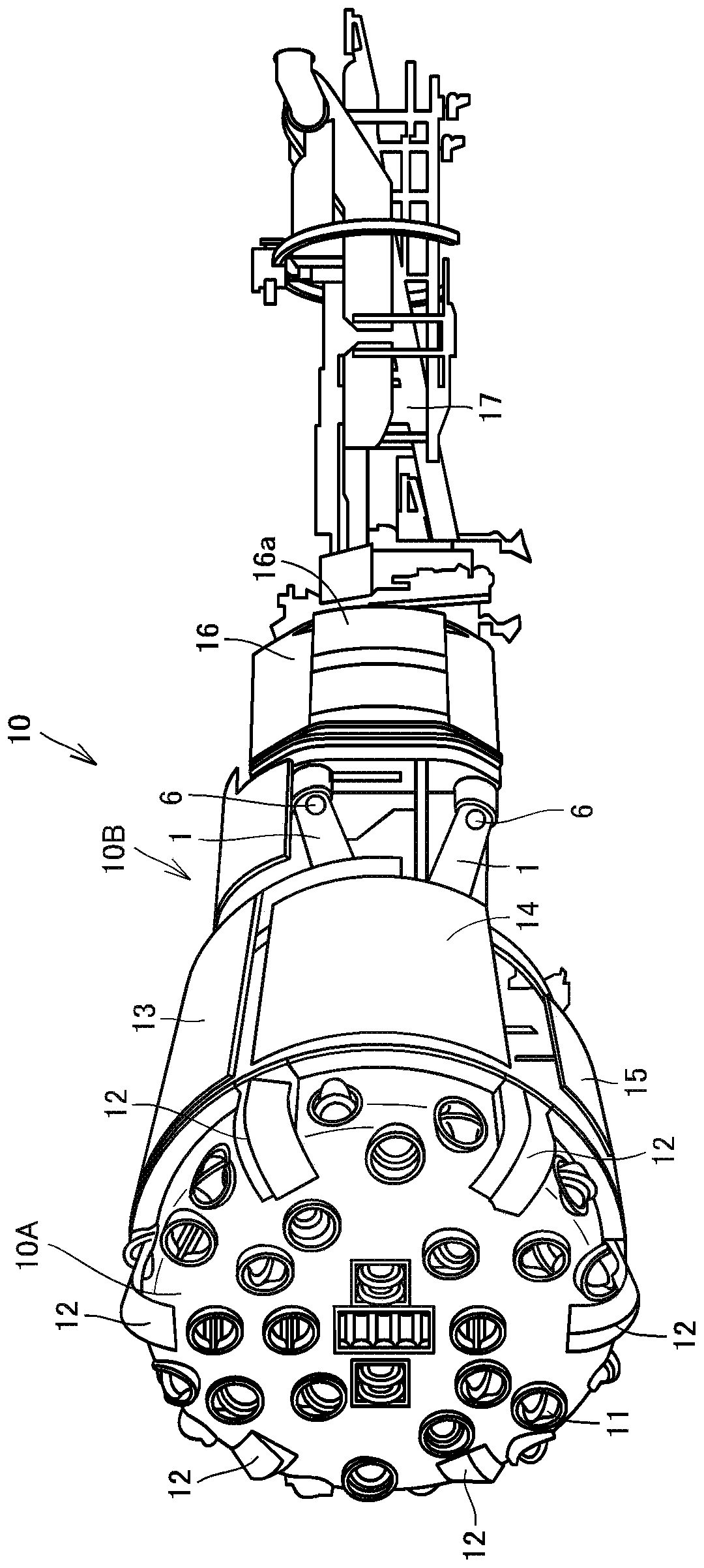

[0015] figure 1 It is a perspective view schematically showing the structure of the tunnel boring machine 10 in one embodiment. Such as figure 1 As shown, the tunnel boring machine 10 excavates underground by rotating the cutter head 10A in a state supported by the main shoe 16 (a shoe) on the tunnel wall in the ground. The tunnel boring machine 10 has a cutter head ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap