A Reliability Test Method of Meta-action Assembly Unit

A technology of assembly unit and test method, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as heavy workload, small realizability, and inaccurate results, and achieve precise reliability Analysis, improved accuracy, and easy storage of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

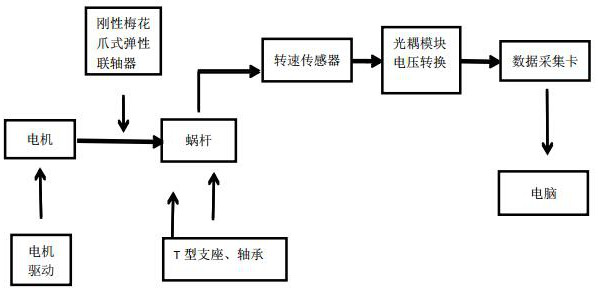

[0027] A method for reliability testing of a meta-action assembly unit (worm screw meta-action assembly unit), comprising the following steps:

[0028] (1) The mechanical and electrical products to be tested are directly decomposed into meta-action assembly units according to the structural decomposition method.

[0029] (2) Determine the specific composition of the meta-action assembly unit according to the requirements of the electromechanical product and the definition of the meta-action assembly unit.

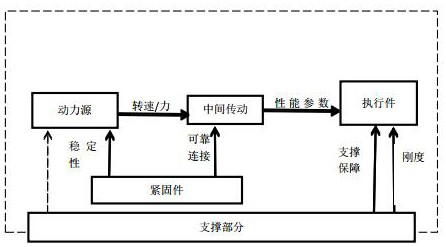

[0030] The concrete composition of described meta-action assembly unit (referring to figure 1 ), including five parts: power source, support, executive, intermediate transmission and fasteners. And the functions of the five parts are: the power source is used to provide the power of the meta-action movement, including the motor directly providing power and the power output by the meta-action movement; the support is used to support the parts of the actuator; The actuator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com