Performance Evaluation Method of Two-Machine Pipeline Considering Sleep Strategy

An assembly line and machine technology, applied in the direction of instruments, data processing applications, calculations, etc., can solve the problem of less research on buffer control strategies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

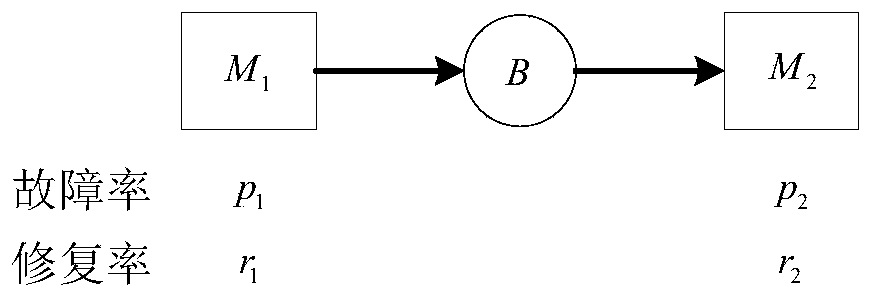

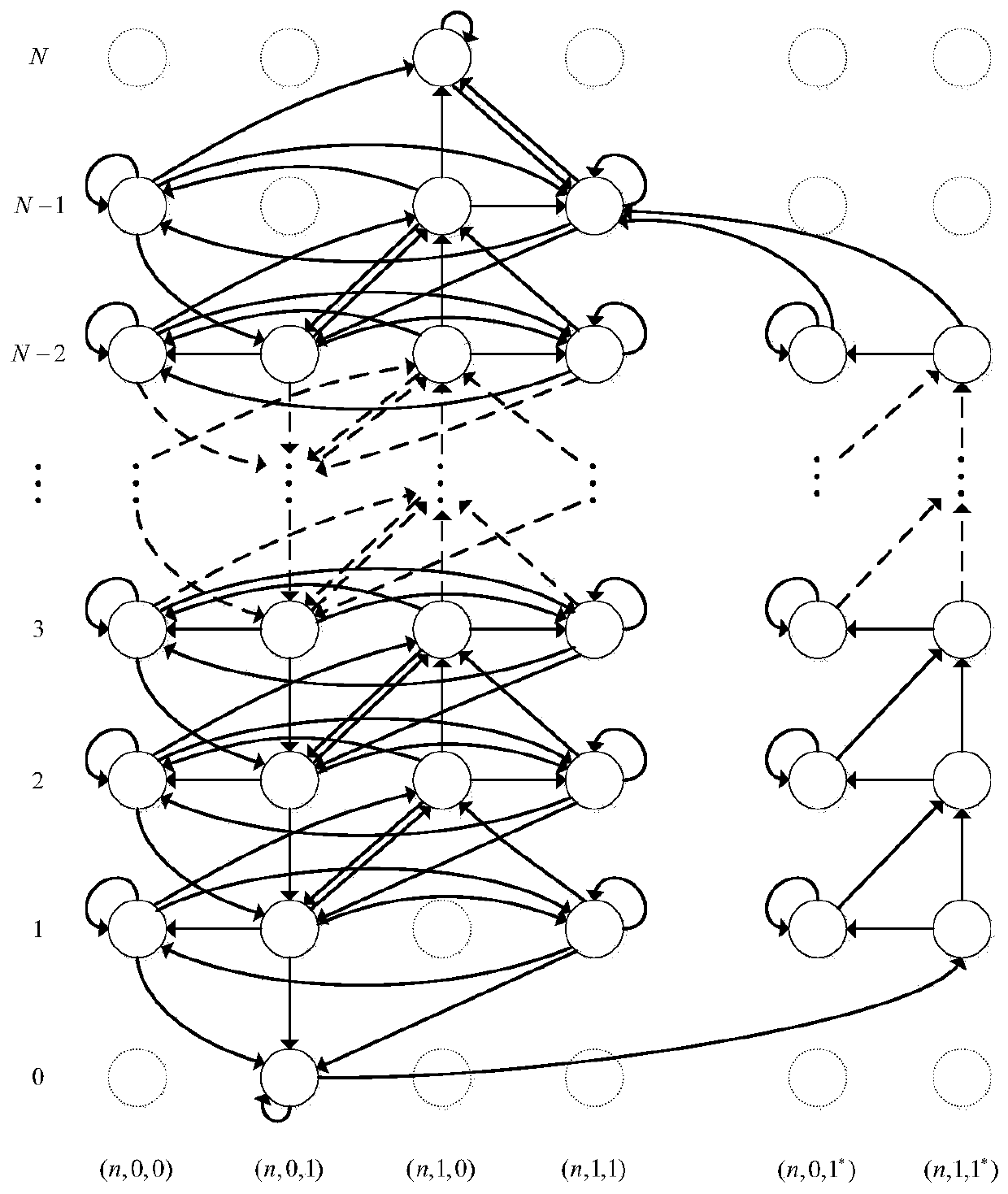

[0090] This embodiment gives the applicant's specific research process: firstly, the dormancy strategy is given, and the analytical method is used to model the two-machine assembly line considering the dormancy strategy, and the flow conservation of the analytical model is proved; secondly, the established The analytical model of the two-machine assembly line considering the dormancy strategy was solved, and performance indicators such as production line efficiency, effective efficiency, and downtime rate were obtained; finally, the effectiveness of the analytical model was analyzed through comparative experiments, and the effectiveness of the patented method was verified. rationality.

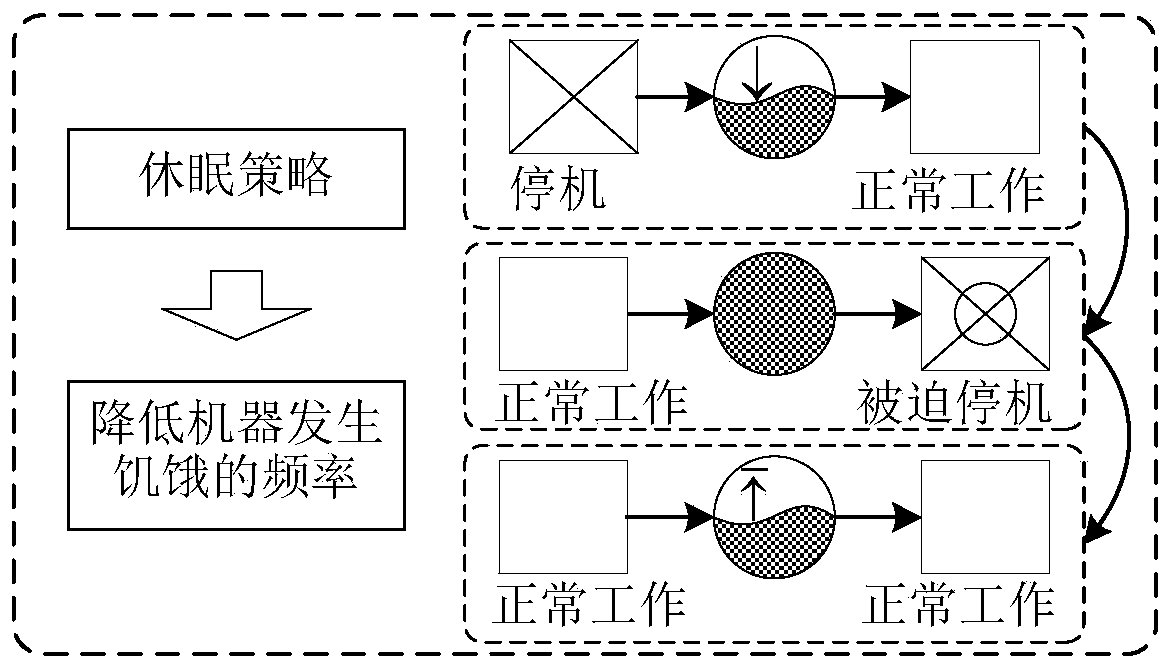

[0091] (1) Dormancy policy definition

[0092] Dormancy strategy: When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com