An intelligent frequency conversion control method for the circulating fan in the descending intensive curing barn during tobacco leaf curing

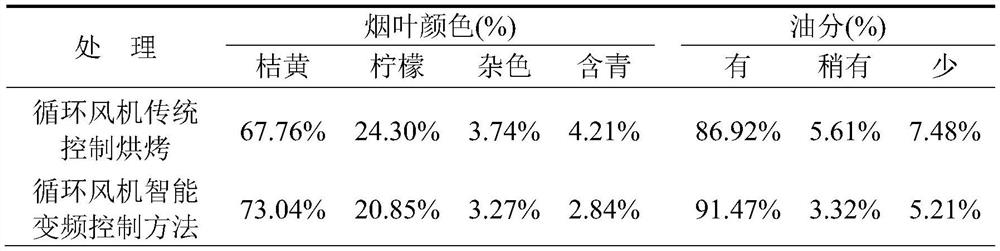

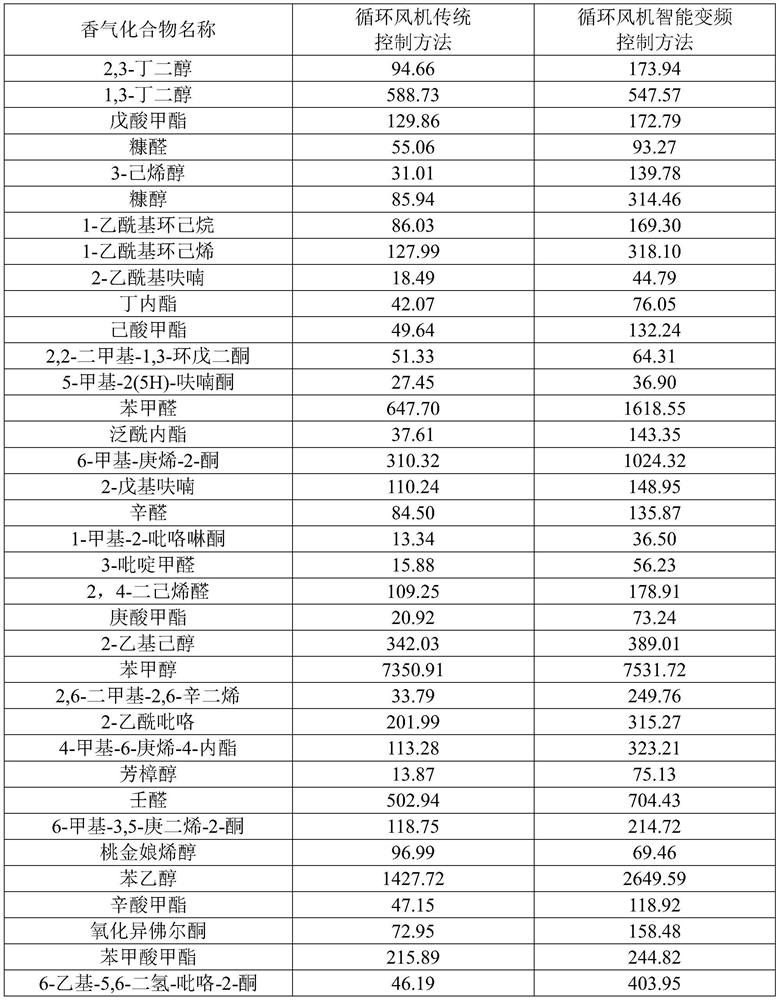

A circulating fan and frequency conversion control technology, which is applied in the field of flue-cured tobacco curing, can solve the problems of reduced aroma, light color of cured tobacco leaves, and reduced oil content, and achieve the effects of improving softness, avoiding stiffness, and enhancing chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] With existing roast equipment, the total power of the circulating fan is 2.2kW, and the conventional method (control) and circulating fan according to the invention are set, and the intelligent variable frequency control (processing) is performed, and the specific operation is as follows:

[0060] Control: When the target temperature is ≤ 40 ° C, the circulating fan is set to a low-grade control; when the target temperature is ≤ 54 ° C, the circulating fan is set to high-grade control; when the target temperature is 54 ° C; the circulating fan is set to the low-end control ( Remarks, high-grade fan speed is 1440 rpm, and the low-grade fan speed is 960 rpm.).

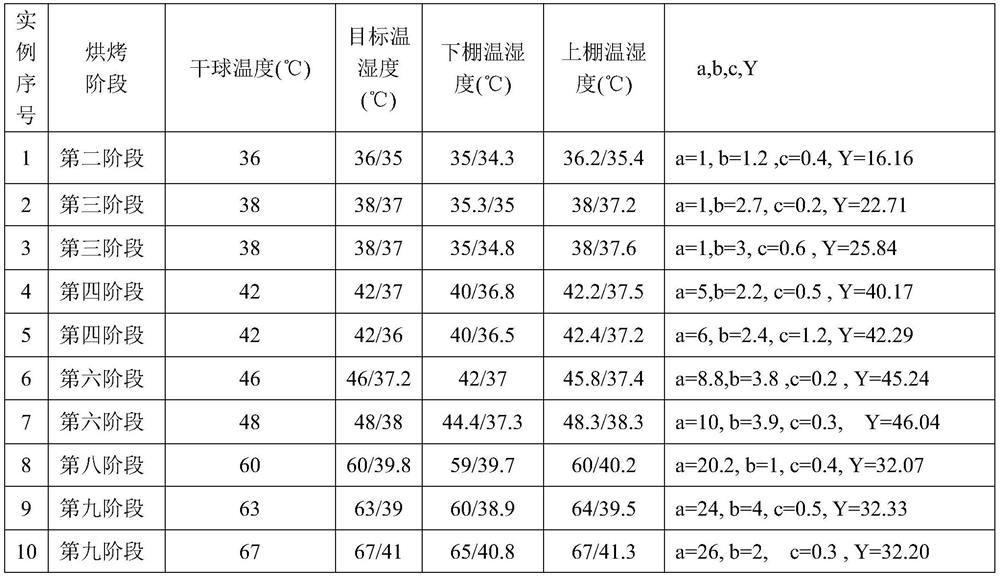

[0061] Processing: According to the method of the present invention, after the tobacco leaves are loaded into the roast room, the intelligent variable frequency regression equation is constructed in order, each stage cycle fan frequency is adjusted according to the intelligent frequency conversion regression equation:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com