Feeding structure of filter

A filter and feeding technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of reduced filtration capacity, affecting product quality, uneven distribution of solids in the half-moon tank, etc., to improve filtration capacity, The effect of high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

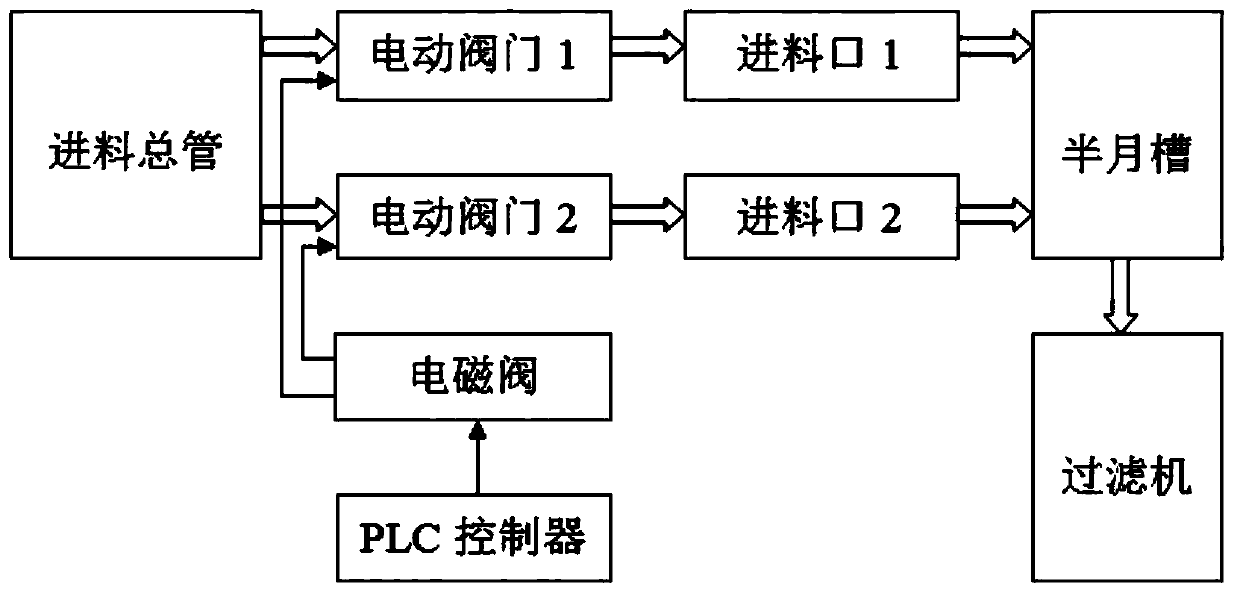

[0009] Such as figure 1 As shown, a filter feeding structure of the present invention includes a feed main pipe, and is characterized in that: the feed main pipe is connected to the electric valve 1 and the electric valve 2 through pipelines, and the electric valve 1 and the electric valve 2 are respectively It is connected to the half-moon tank through the feed port 1 and the feed port 2, and the half-moon tank is connected to the filter through the pipeline; the electric valve 1 and the electric valve 2 are electrically connected to the solenoid valve, and the solenoid valve is electrically connected to the PLC control device.

[0010] Compared with the prior art, the beneficial effects of the present invention are:

[0011] In the feed structure of a filter of the present invention, the previously used manual valve is improved into an electric valve, and the valve opening is uniformly controlled by a solenoid valve, and the solenoid valve is intelligently controlled by PLC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com