Milk static and dynamic high-pressure combined sterilization process and application thereof

A technology of milk and technology, which is applied in the field of fruit juice processing and food processing, can solve the problems of high energy consumption and great influence on the taste of milk, and achieve the effects of low energy consumption, unique flavor and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

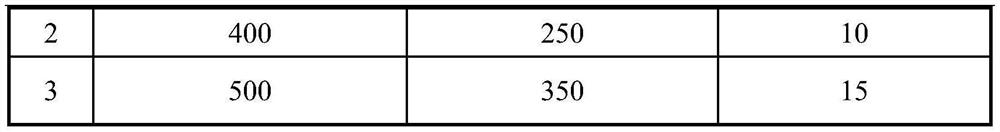

Examples

Embodiment 1

[0021] The invention provides a static and dynamic high-pressure combined sterilization process for milk, the sterilization process comprising the following steps:

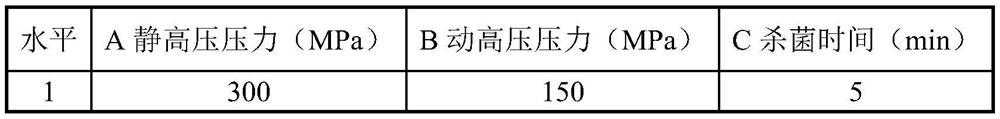

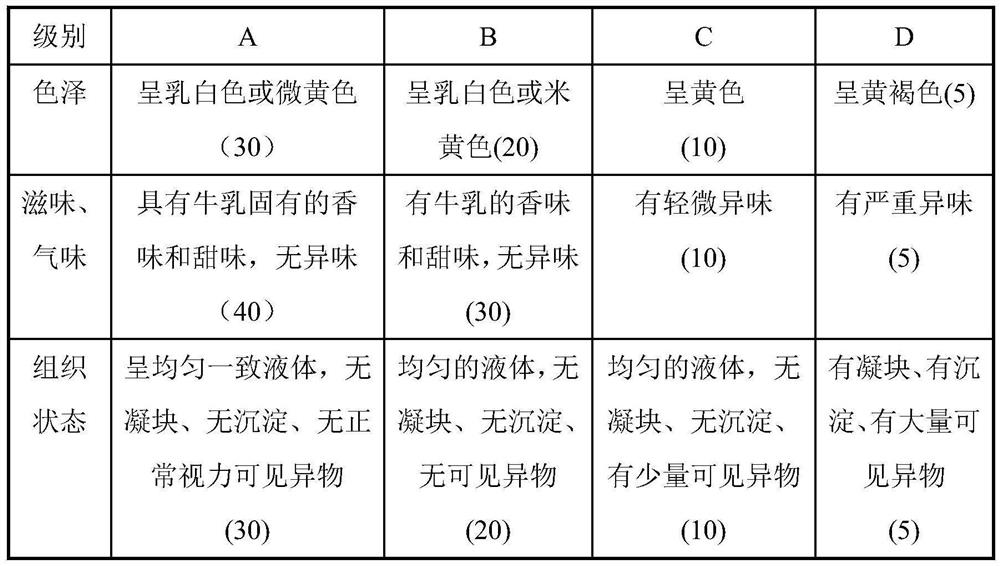

[0022] The milk is centrifugally purified or filtered with 200-400-mesh nylon cloth to remove mechanical impurities visible to the naked eye; the purified milk is homogenized at room temperature at 16MPa-22MPa normal pressure; the prepared homogenized milk is prepared at 300MPa- Sterilize under 600MPa static pressure for 5min-20min, then carry out high-pressure homogeneous sterilization under 150MPa-400MPa pressure; immediately cool down to below 10°C, fill in sterilized packaging containers and store in 2- Store in a refrigerator at 8°C.

[0023] The application of a static and dynamic high-pressure combined sterilization process for fresh milk provided by the invention.

[0024] Furthermore, the present application also provides a non-vegetable protein beverage prepared by a milk static-dynamic high-pressure co...

Embodiment 2

[0026] On the basis of Example 1, this embodiment provides a static and dynamic high-pressure joint sterilization process for milk, wherein the milk is centrifugally purified or filtered with 200-400-mesh nylon cloth to remove mechanical impurities visible to the naked eye; The milk is homogenized under 16MPa and normal pressure at room temperature; after being sterilized under the static pressure of 300MPa for 5 minutes, and then subjected to high-pressure homogenization and sterilization under the pressure of 150MPa; the temperature is immediately lowered to below 10°C, and filled in sterilized containers. Store in a cold storage at 2-8° C. in a packaging container to obtain sterilized milk.

Embodiment 3

[0028] On the basis of Example 1, this embodiment provides a static and dynamic high-pressure joint sterilization process for milk, wherein the milk is centrifugally purified or filtered with 200-400-mesh nylon cloth to remove mechanical impurities visible to the naked eye; The milk is homogenized under 18MPa and normal pressure at room temperature, sterilized under the static pressure of 400MPa for 10 minutes, and then subjected to high-pressure homogenization and sterilization under the pressure of 250MPa; Store in a cold storage at 2-8° C. in a packaging container to obtain sterilized milk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com