The method for removing magnetic substance from lithium carbonate slurry

A technology of lithium carbonate and magnetic substances, which is applied in the direction of separation methods, chemical instruments and methods, lithium carbonate; Effects of reduced demagnetization pressure and high demagnetization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

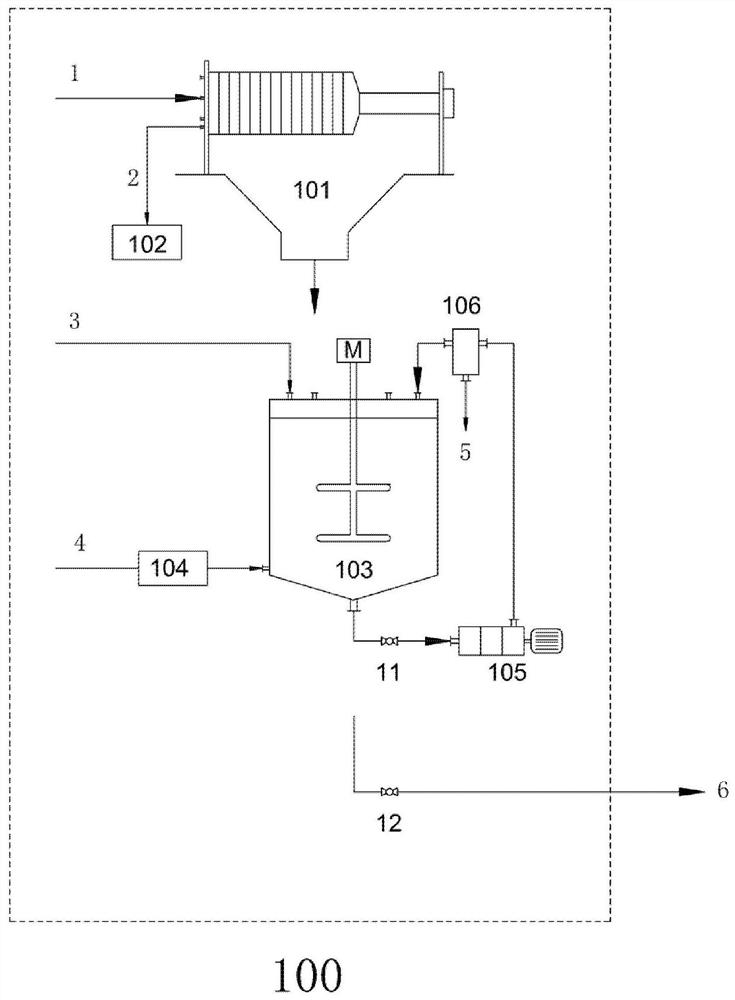

[0065] figure 1 Shown is a process flow according to one embodiment of the present invention, and the lithium carbonate demagnetization device used in the process flow includes a first-stage slurry washing demagnetization system.

[0066] Such as figure 1 As shown, the starch washing and demagnetization system 100 includes a filter mechanism 101 , a filter recovery mechanism 102 , a starch washing mechanism 103 , a steam filter mechanism 104 , a crushing mechanism 105 and a demagnetization mechanism 106 .

[0067] The filter mechanism 101 may mainly include a plate and frame filter press. It is used in the first stage of pulp washing to separate the lithium carbonate slurry generated in the conversion lithium precipitation section from solid to liquid to obtain a filter cake and filtrate containing impurities, wherein the filter cake enters the pulp washing mechanism 103 of this stage, and the impurity-containing filtrate is obtained. The filtrate of impurities enters the fi...

no. 2 approach

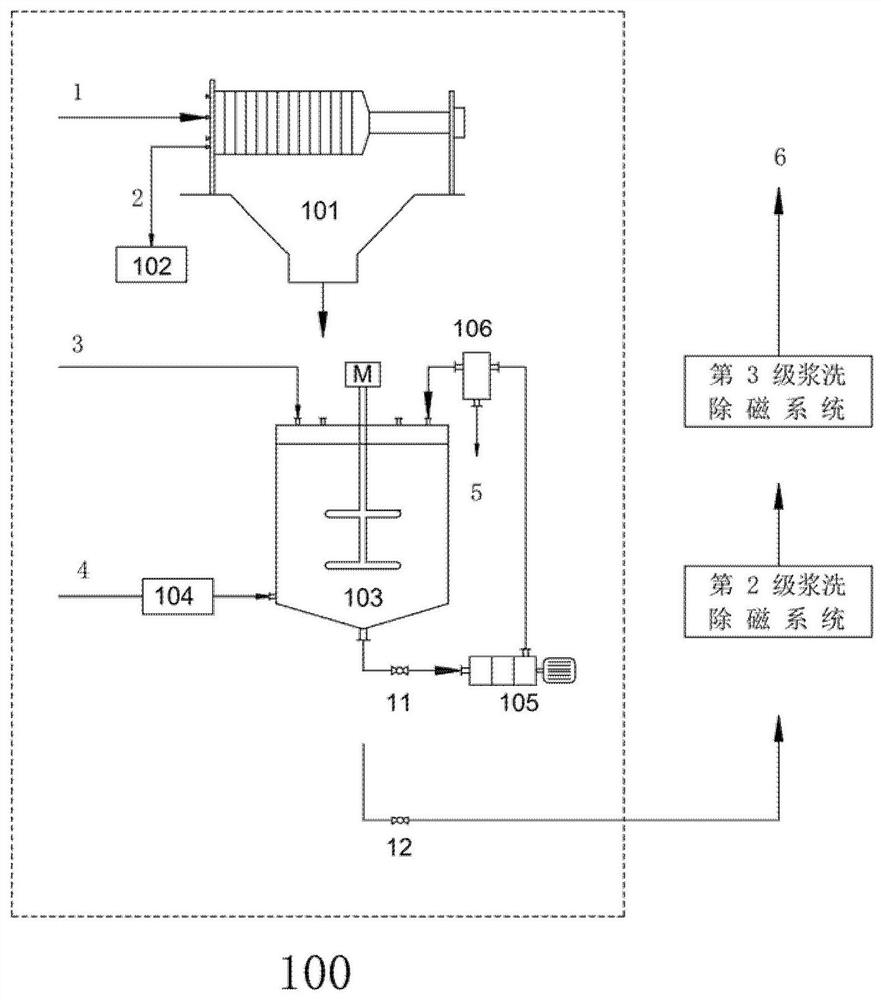

[0078] figure 2 Shown is a process flow according to another embodiment of the present invention, the lithium carbonate demagnetization device used in the process flow comprises a three-stage slurry washing demagnetization system.

[0079] exist figure 2 Among them, the 2nd and 3rd stage washing and demagnetizing systems are the same as the 1st stage washing and demagnetizing system, and the technological process adopted is also the same, and the process parameters can be the same or different. Among them, the filter mechanism of the second stage and the third stage is connected to the lithium carbonate slurry processed by the previous stage of starch washing and demagnetization system, and the same treatment as in the first stage of starch washing and demagnetization system (filtering, starch washing, crushing, demagnetization), realize three-stage demagnetization by pulp washing, and obtain the final demagnetization product 6 (lithium carbonate slurry demagnetized by pulp...

Embodiment

[0082] Hereinafter, the present invention will be described in detail with reference to Examples to specifically describe the present invention. However, the embodiments of the present invention may be modified into various other forms and the scope of the present invention should not be construed as being limited to the embodiments described below. The embodiments of the present invention are provided so as to more fully describe the present invention to those skilled in the art.

[0083] Unless otherwise specified, the equipment or raw materials in the following examples can be obtained from commercial channels such as general markets or can be easily obtained by self-made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com