Machine tool workpiece demagnetization control device and method

A control device and demagnetization technology, which is applied in the field of demagnetization, can solve the problems of reduced efficiency and duty cycle, and achieve the effects of reducing the risk of component damage, improving demagnetization efficiency, and reducing the difficulty of equipment operation and setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

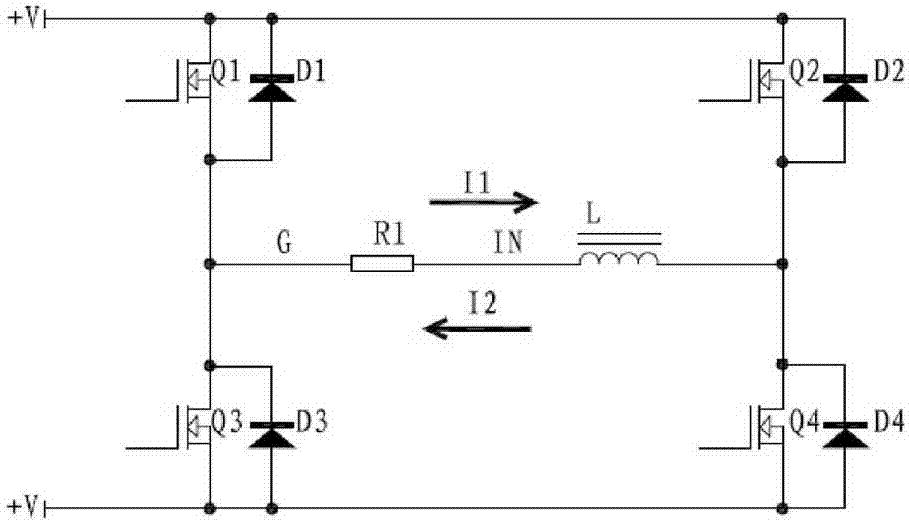

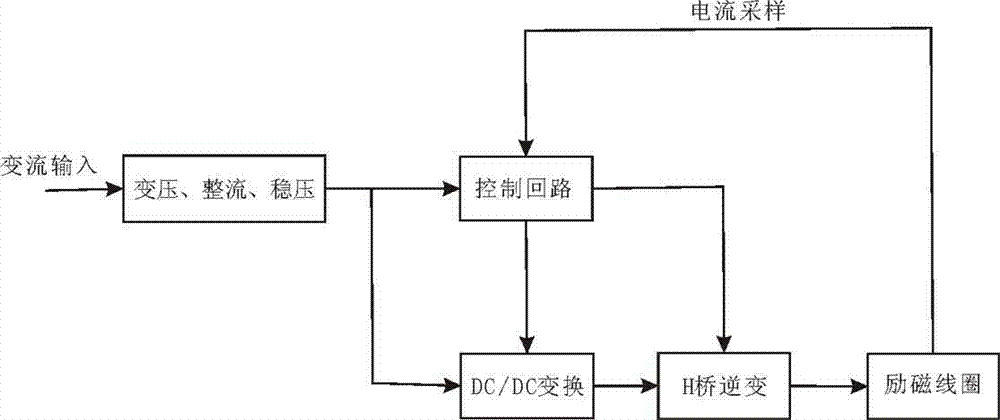

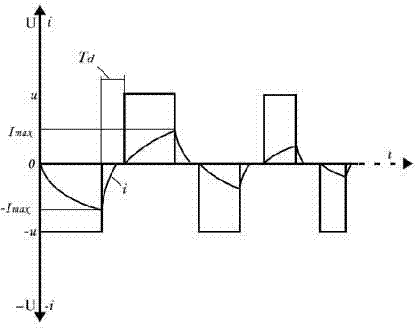

[0017] The present invention is further illustrated by taking the electromagnetic chuck controller of a grinder as an example. The invention introduces parameter identification technology and DC / DC conversion technology into the design of electromagnetic chuck controller, such as figure 2 As shown, the power supply input terminal and the power supply output terminal are included. The power supply input terminal is electrically connected to the voltage transformation rectification and voltage stabilization circuit. The output terminal of the voltage transformation rectification and voltage stabilization circuit outputs a DC voltage to the H-bridge inverter circuit through the DC / DC conversion circuit. It also includes a control loop composed of a digital signal processor; the control loop collects the information of the excitation coil through the AD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com