Multi-stage series drawer type permanent magnet magnetic substance removing device

A technology of magnetic material and magnetic device, which is applied in the field of multi-stage serial drawer type permanent magnet removing magnetic material device, can solve the problems of insufficient layers of magnetic rods, uneven distribution of iron remover, uneven material dispersion, etc., so as to increase the contact probability. , Increase equipment utilization and demagnetization efficiency, the effect of demagnetization efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described.

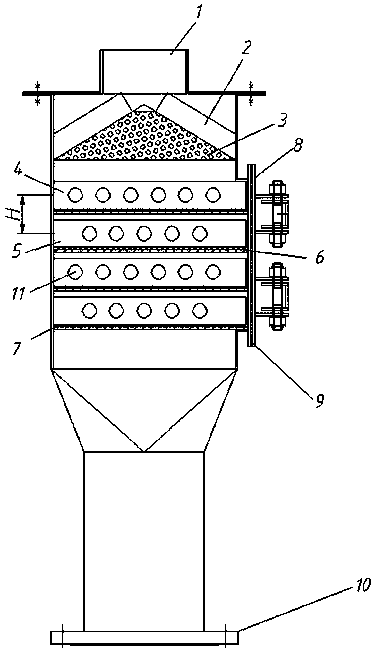

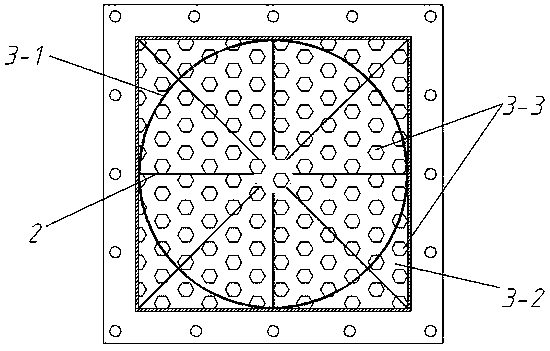

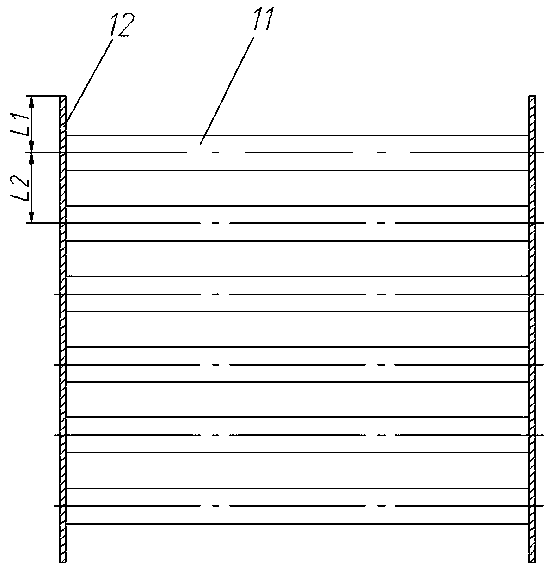

[0024] see Figure 1-4 As shown, the technical solution adopted in this specific embodiment is: it includes the iron remover housing, the uniform material device 3, the magnetic device, the quick-opening door panel 8, and the flange 10; the iron remover housing is made of a stainless steel plate with a thickness of 4 mm ; The top of the iron remover housing is provided with a material inlet 1; the uniform material device 3 is located below the material inlet 1, and the uniform material device 3 is welded with the rib 2 and fixed on the inner wall of the iron remover shell; the angle between the rib 3 is 120 °; The equalizing device 3 is composed of the top conical distributor 3-1 and the sieve plate 3-2; the conical distributor 3-1 and the sieve plate 3-2 are welded into a whole, and the conical distributor 3-1 and the sieve plate 3- 2 are evenly covered with sieve holes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com