Punching device for building fastener production

A technology for punching devices and fasteners, which is applied in the direction of stripping devices, metal processing equipment, manufacturing tools, etc., can solve problems such as not easy to fall, affect the continuity of punching holes, reduce the production efficiency of building fasteners, etc., and achieve a smooth downward movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

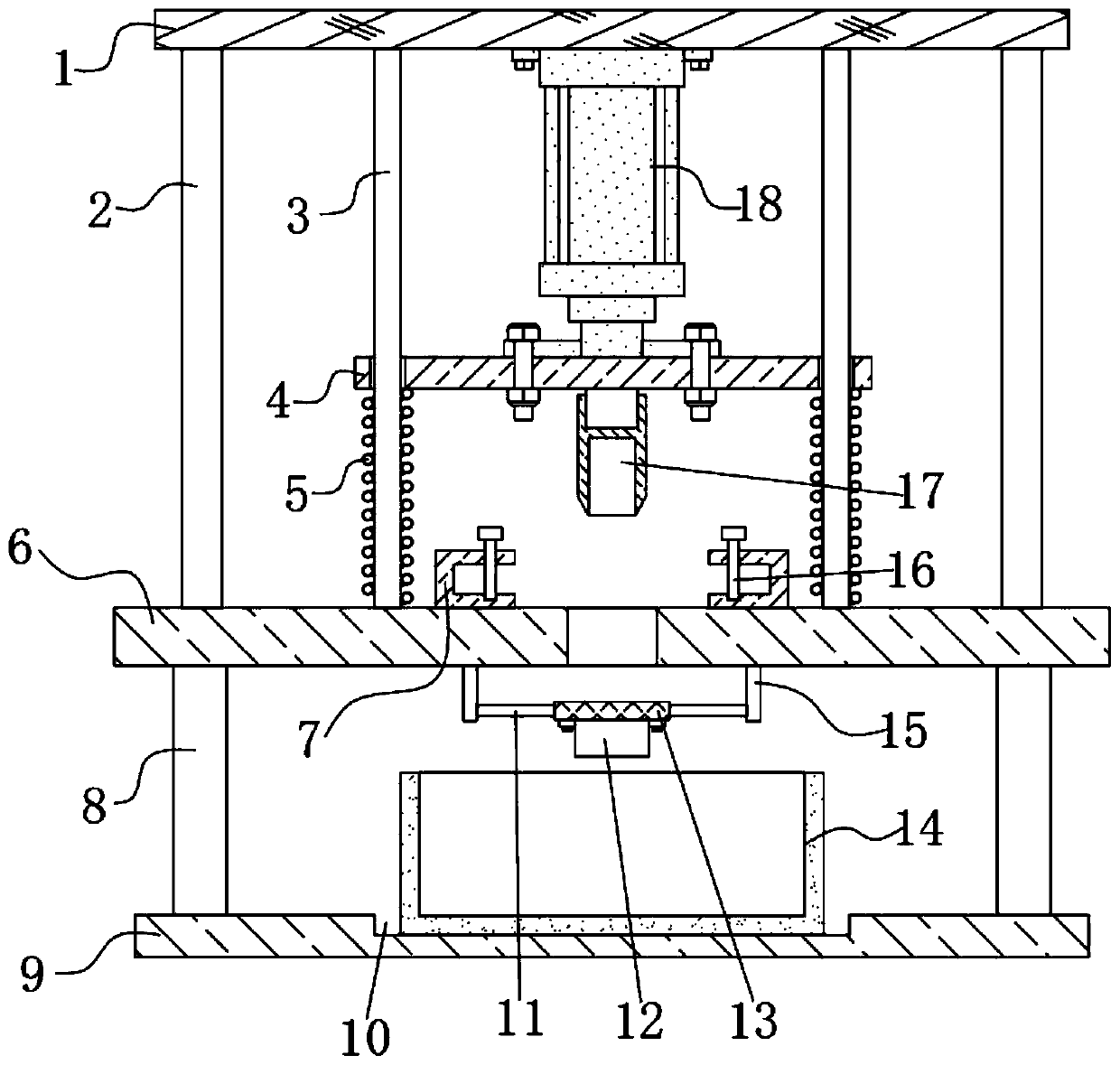

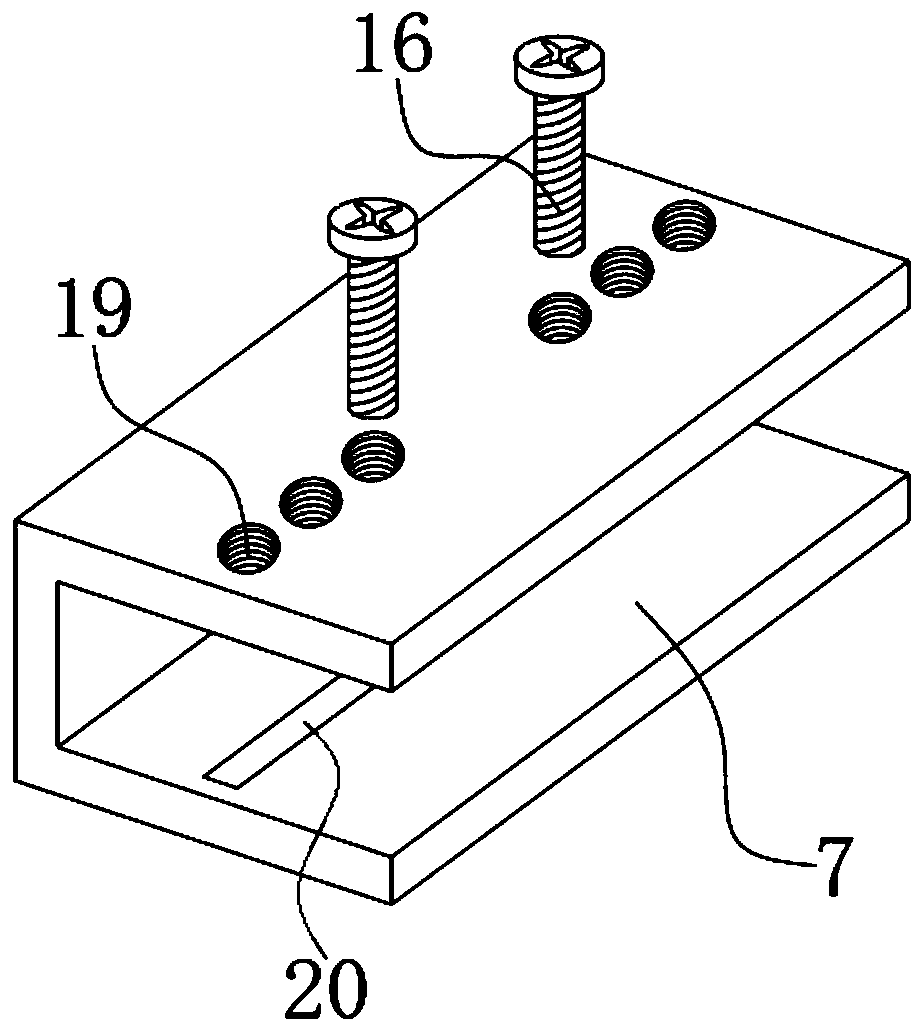

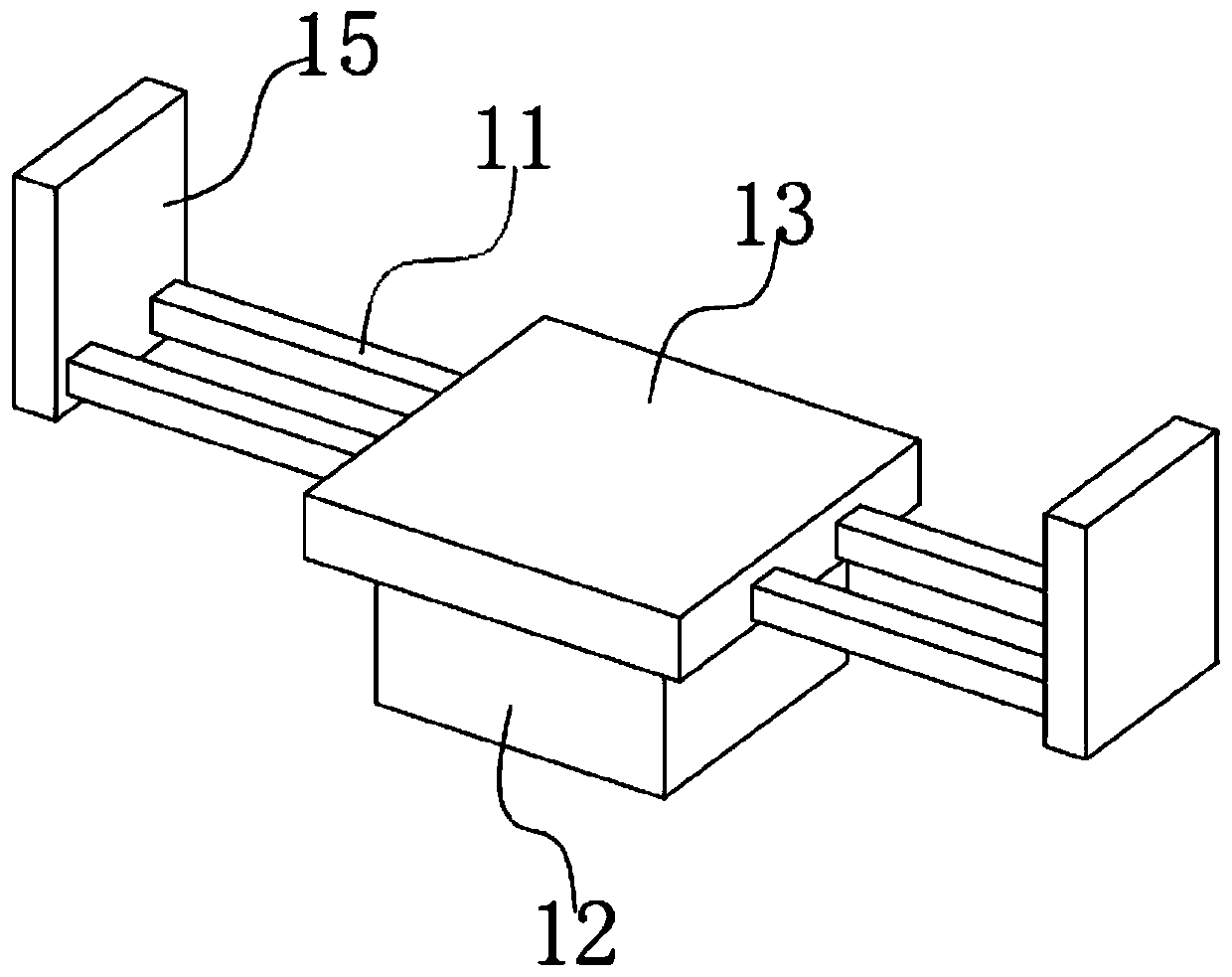

[0025] refer to Figure 1-3 , a punching device for the production of building fasteners, including a platen 6 and a punching mechanism, the top outer wall of the platen 6 is provided with a blanking hole, and the top outer wall of the platen 6 is fixed with two U-shaped seats 7 by bolts, There are two sets of threaded holes 19 on the top of the U-shaped seat 7, and the screw rods 16 are inserted into the internal threads of the two sets of threaded holes 19. Before punching, insert the two ends of the sheet into the two U-shaped seats 7 respectively. According to the size of the sheet, insert the screw 16 into the threaded hole 19 at a suitable position, and use the screw 16 to press the sheet tightly, thus completing the fixing of the sheet, so that the subsequent more accurate punching, the platen The outer wall of the bottom of 6 is welded with two vertical plates 15, and the outer wall of the opposite side of the two vertical plates 15 is welded with two cross bars 11, an...

Embodiment 2

[0034] refer to Figure 4 , a punching device for the production of building fasteners. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, the inner wall of the bottom of the groove 10 is welded with a plurality of pads 21 with a semicircular end structure.

[0035] Working principle: when in use, the pad 21 with a semicircular end surface structure can reduce the contact area with the bottom of the material receiving box 14, so that the staff can take out the material receiving box 14 more labor-saving in the later stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com