Novel four-channel full-automatic handkerchief paper production line

A four-channel, fully automatic technology, applied in the direction of machining/deformation, can solve problems affecting people's work efficiency, achieve the effect of moving down stably and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

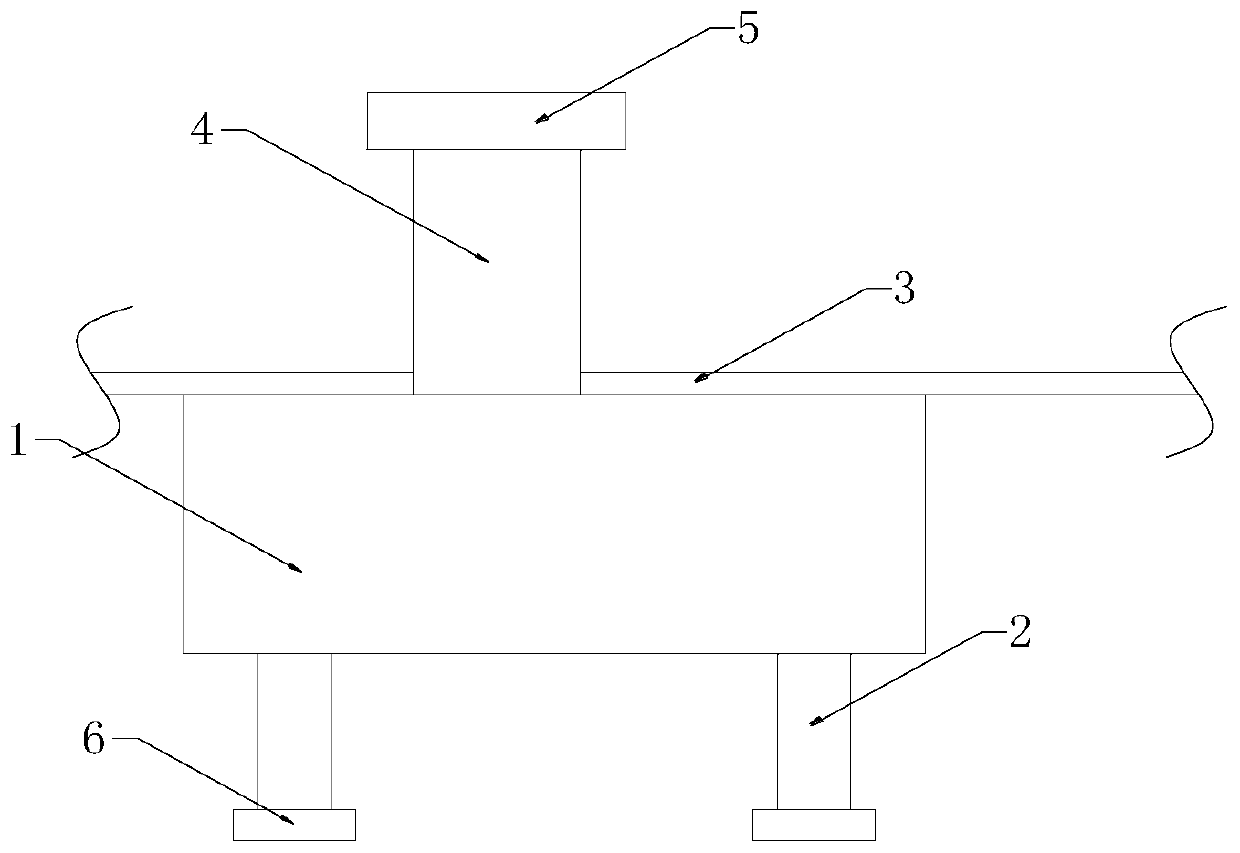

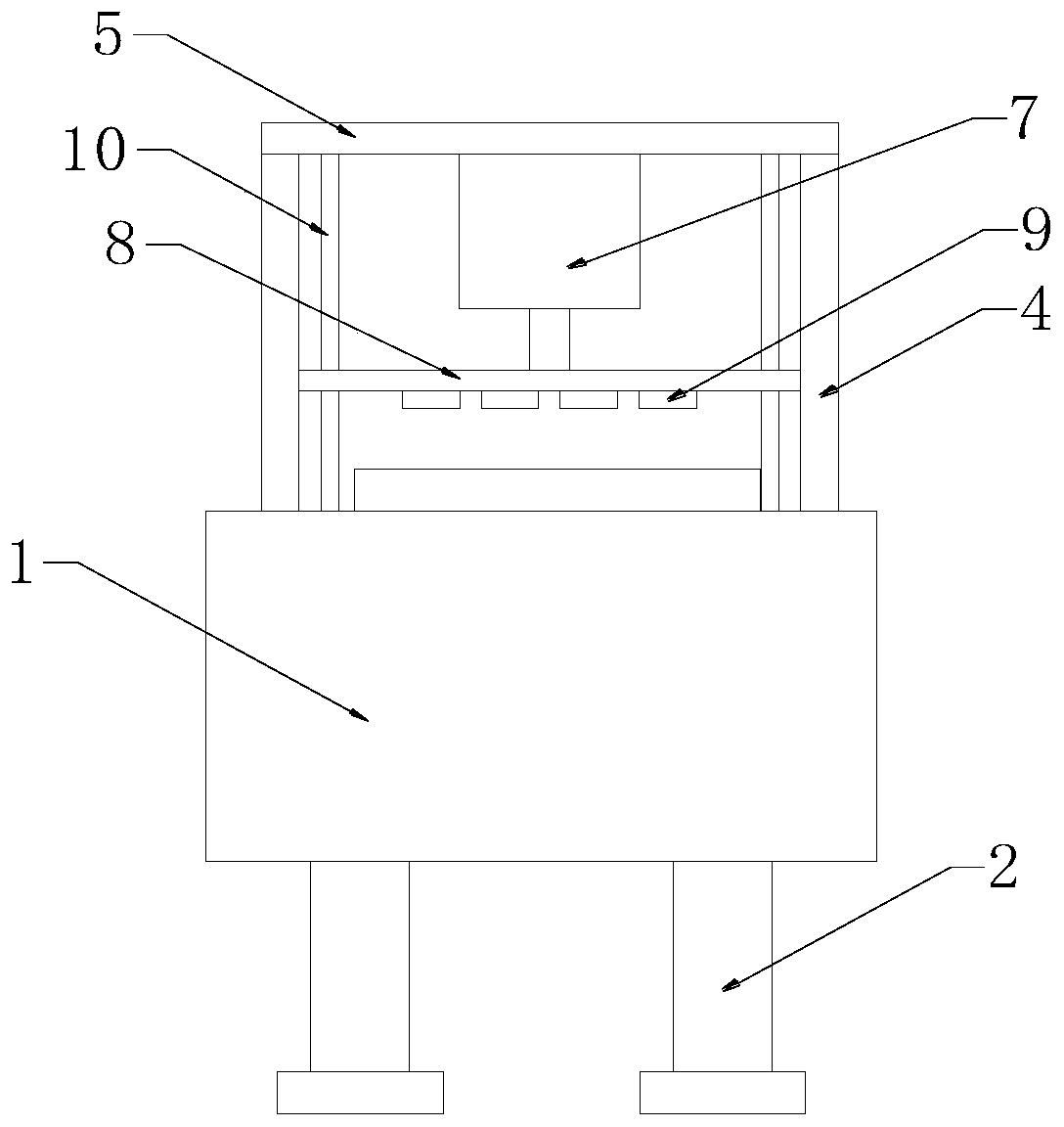

[0015] Example: such as figure 1 with figure 2 As shown, a novel four-channel automatic handkerchief paper production line of the present invention comprises a table body 1 and four legs 2, and the four legs are all fixedly connected to the four corners of the bottom end of the table body 1, and the top of the table body 1 The middle part is provided with a conveyor belt 3, both sides of the top of the table body 1 are fixedly provided with support plates 4, a top plate 5 is fixedly provided between the tops of the two support plates 4, and an extrusion plate 8 is fixedly provided at the middle of the bottom of the top plate 5. , the middle part of the bottom end of the extruding plate 8 is sequentially arranged on four extruding blocks 9 from left to right, through the four extruding blocks 9 arranged, it is convenient for people to extrude a plurality of handkerchief paper extruding papers at the same time, improving people's As a result, the downward movement of the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com